MS 194 T

English

28

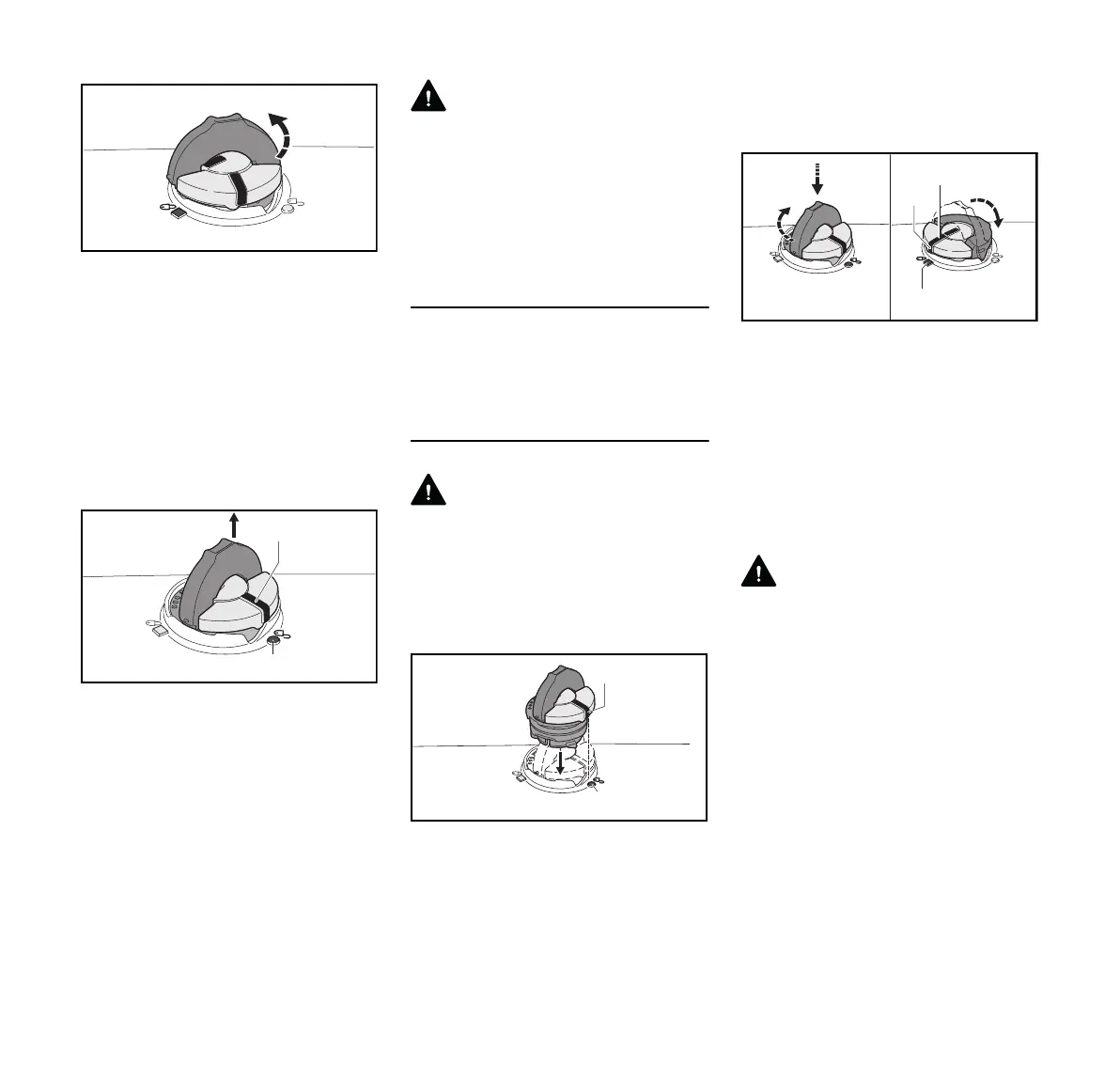

N While maintaining steady,

downward pressure, turn the cap

slowly counter-clockwise to the vent

position (2), approximately a

1/8 turn of the cap.

N If any significant venting occurs,

immediately re-seal the tank by

turning the cap clockwise to the

closed position. Allow the saw to

cool further before attempting to

open the tank.

N Turn the cap to the open position (3)

only after the contents of the tank

are no longer under pressure. In the

open position, the exterior

positioning mark (4) on the cap will

line up with the "unlocked"

symbol (5) on the fuel tank housing.

N Remove the fuel filler cap.

WARNING

Never remove the cap by turning it

directly to the open position. First allow

the saw to cool adequately and then

release any residual pressure at the vent

position (2). Never attempt to remove

the cap while the engine is still hot or

running.

Refueling

Take care not to spill fuel while fueling

and do not overfill the tank – leave

approximately 1/2" (13 mm) air space.

Closing

WARNING

An improperly tightened fuel filler cap

can loosen or come off and spill

quantities of fuel. To reduce the risk of

fuel spillage and fire from an improperly

installed fuel cap, correctly position and

tighten the cap in the fuel tank opening:

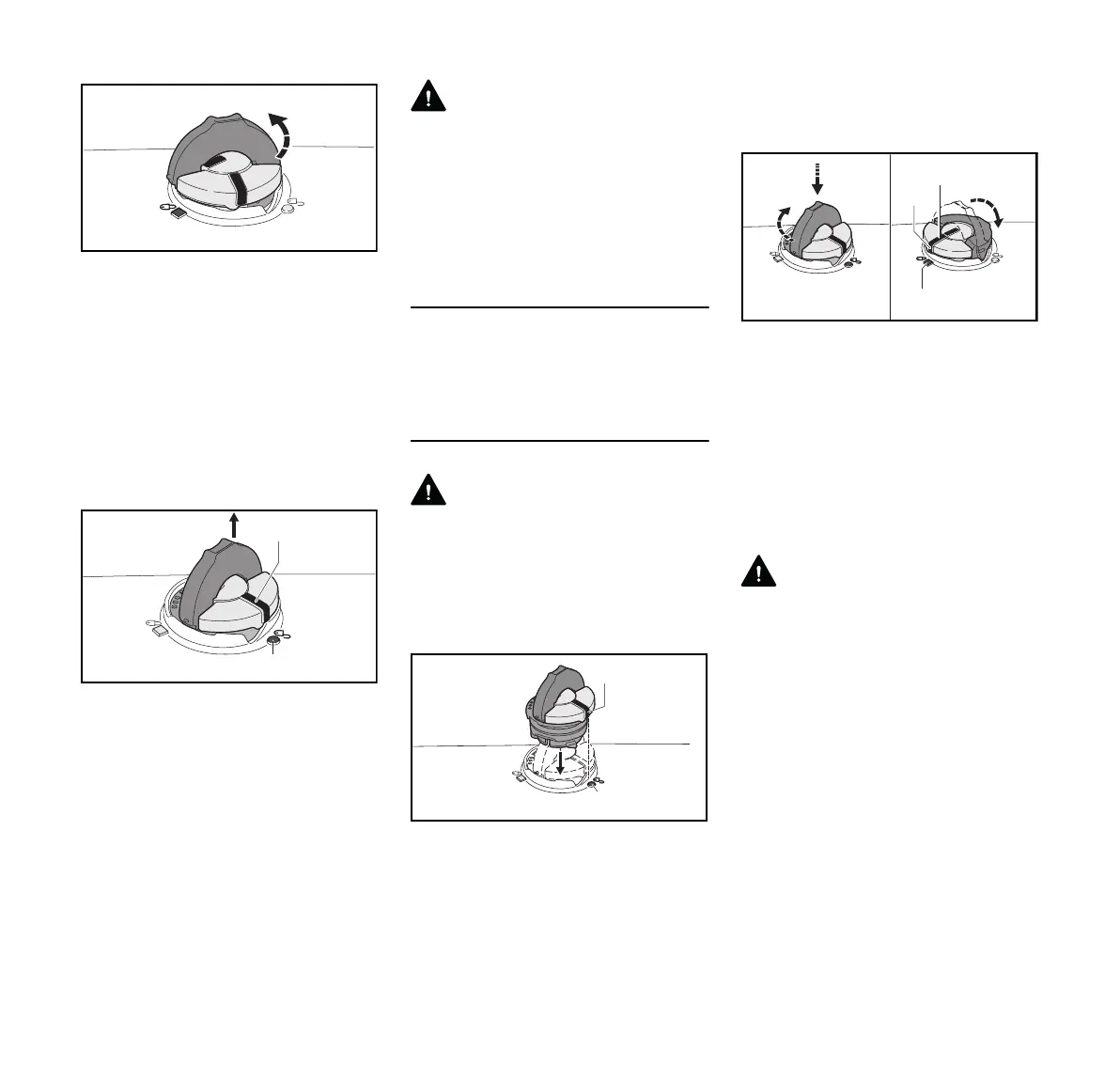

N Raise the grip on the top of the cap

until it is upright at a 90° angle.

Insert the cap in the fuel tank

opening with the exterior positioning

mark (1) lined up with the

"unlocked" symbol (2) on the fuel

tank housing.

N Using the grip, press the cap down

firmly while turning it clockwise to

the closed position (approximately

1/4 turn). In the closed position, the

interior (4) and exterior (1)

positioning marks will align with the

"locked" symbol (3) on the fuel tank

housing.

N Fold the grip flush with the top of the

cap and check for tightness.

WARNING

If the grip does not lie completely flush

with the cap or the detent on the grip

does not fit in the corresponding recess

in the tank opening, or if the cap is loose,

the cap is not properly seated and you

must repeat the above steps. Also refer

to the procedure below for returning the

base of the cap to the proper starting

position for installation.

3

4

5

0000-GXX-6425-A0

3

1

4

0000-GXX-6427-A0

Loading...

Loading...