MS 194 T

English

29

If the filler cap will not engage into the

fuel tank housing

If the cap does not drop fully into the fuel

tank opening when the positioning

marks (1, 2) line up, or if it does not

tighten properly when turned, the base

of the cap may be prematurely rotated in

relation to the top. Such misalignment

can result from handling, cleaning or an

improper attempt at tightening.

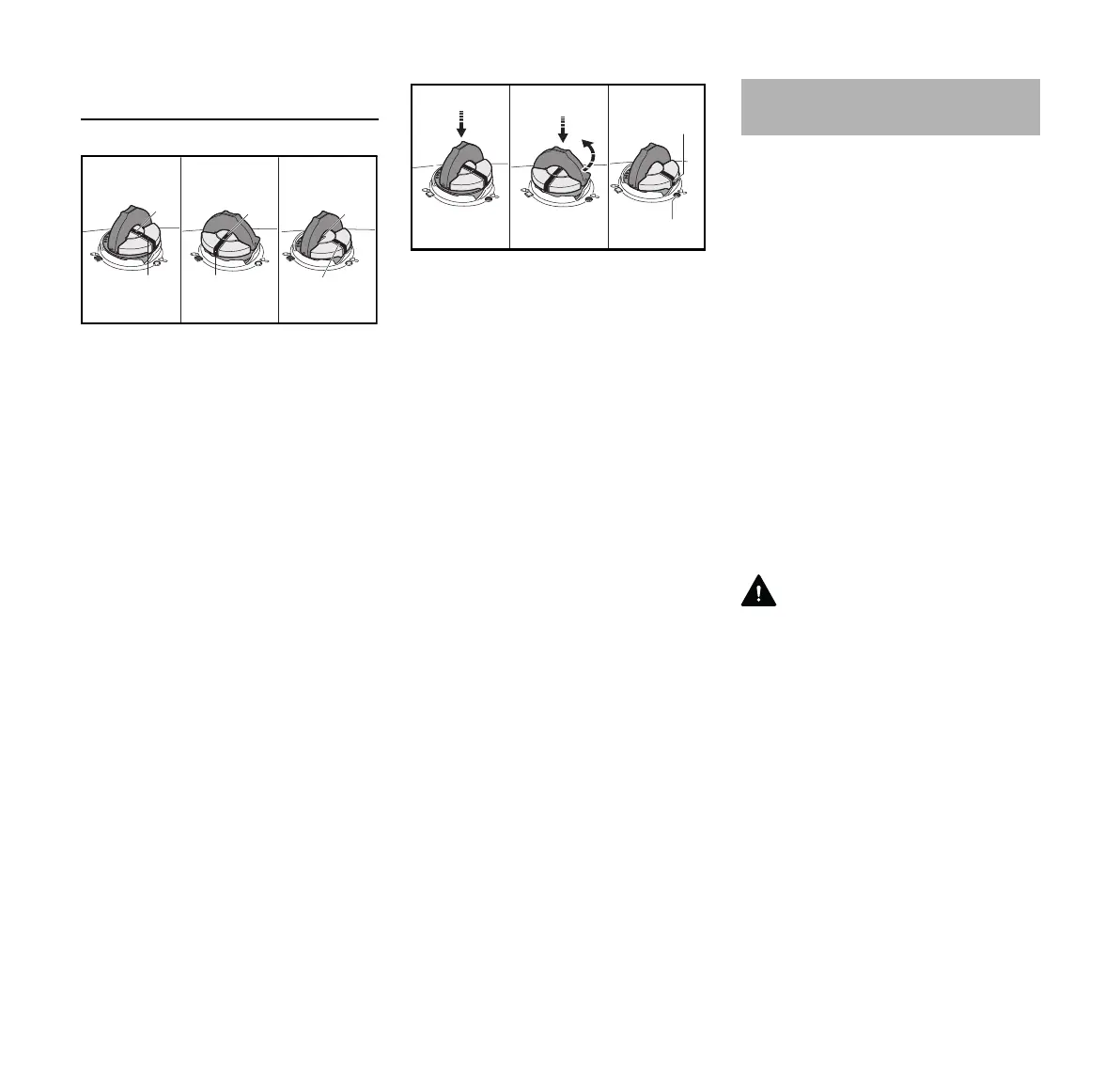

– Illustrations A and B: The base of

the cap is prematurely rotated to the

closed position and is not in the

correct starting position for

installation. The tank will not seal in

this configuration. Note: in

Illustrations A and B, the interior

positioning marks (1) are in line with

the exterior position marks (2).

– Illustration C: The bottom of the cap

is in the correct starting position for

installation. Note: In Illustration C,

the interior positioning mark (1) is

under the grip and not in line with

the outer position mark (2).

To return the base of the cap to the

proper starting position for installation:

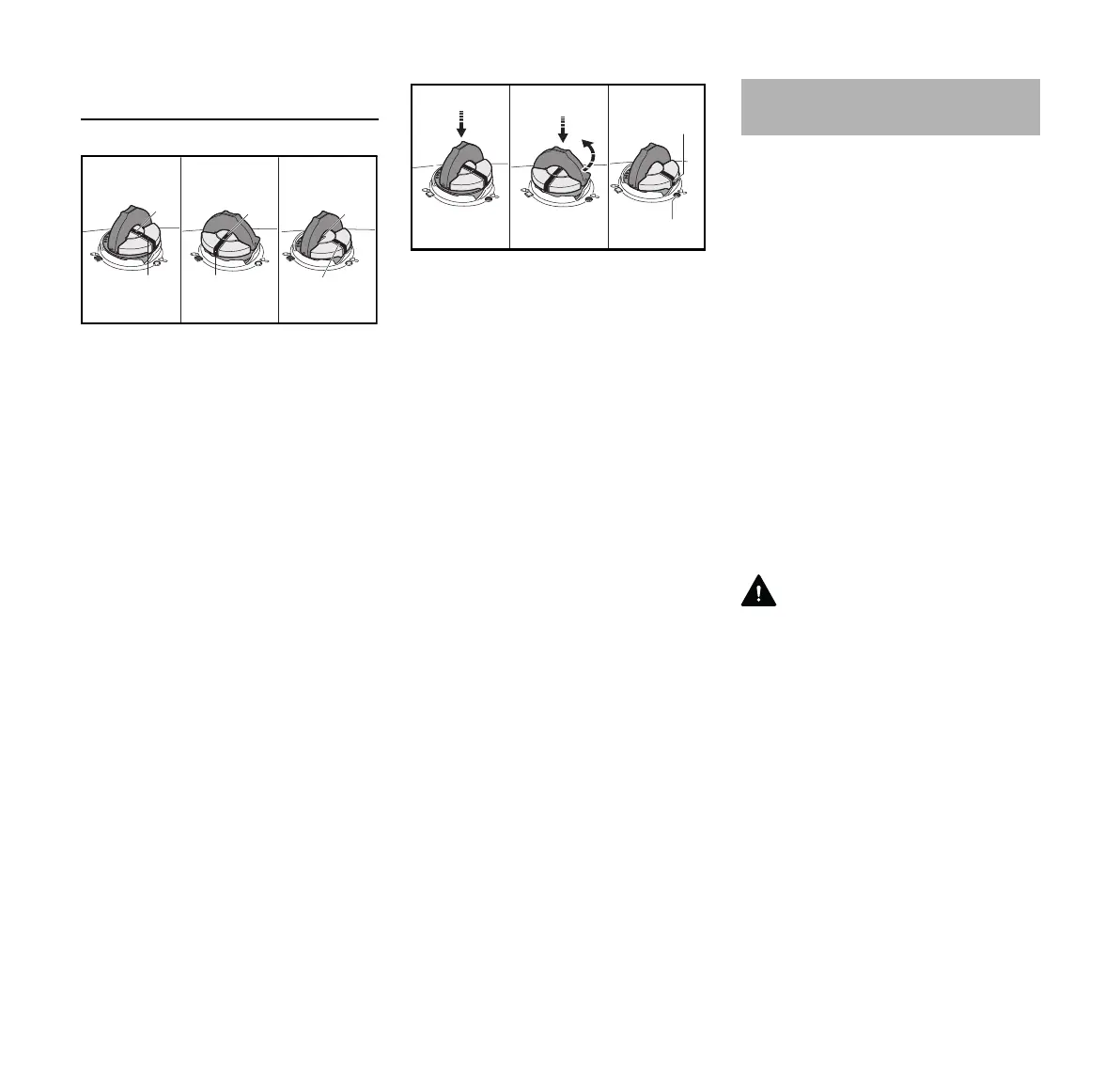

N Drop the cap into the fuel tank

opening (A).

N Next, turn the cap counter-

clockwise with slight pressure until it

drops fully into the fuel tank opening

(approximately 1/4 turn) (B). This

will rotate the base of the cap into

the correct starting position for

installation (C). The exterior

positioning mark (1) on the cap will

line up with the "unlocked"

symbol (2) on the fuel tank housing.

The interior positioning mark should

be under the grip and not in line with

the outer positioning mark (1).

N Then, turn the cap clockwise,

closing it normally.

If your fuel cap still does not tighten

properly, it may be damaged or broken.

Stop using the chain saw and take it to

your authorized STIHL dealer for repair.

For automatic and reliable lubrication of

the chain and guide bar – use only an

environmentally compatible quality

chain and bar lubricant. Rapidly

biodegradable STIHL BioPlus is

recommended.

NOTICE

Biological chain oil must be resistant to

aging (e.g. STIHL BioPlus), since it will

otherwise quickly turn to resin. This

results in hard deposits that are difficult

to remove, especially in the area of the

chain drive and chain. It may even cause

the oil pump to seize.

The service life of the chain and guide

bar depends on the quality of the

lubricant. It is therefore essential to use

only a specially formulated chain

lubricant.

WARNING

Do not use waste oil. Renewed contact

with waste oil can cause skin cancer.

Moreover, waste oil is environmentally

harmful.

NOTICE

Waste oil does not have the necessary

lubricating properties and is unsuitable

for chain lubrication.

ABC

1

2

1

2

2

1

0000-GXX-6421-A0

1

2

A

BC

0000-GXX-6422-A1

Chain Lubricant

Loading...

Loading...