STIHL TS 400 14

5.2 Leakage testing

Defective rotary shaft seals and

gaskets or cracks in the castings

cause leaks through which

supplementary air can enter and

change the composition of the

fuel/air mixture taken in.

Above all, this makes it very much

more difficult, if not impossible, to

set the correct idle speed.

In addition, it also prevents a

faultless transition from idle to full

or part-load operation.

The crankcase can be tested to

ensure it is absolutely tight with the

aid of the carburetor / crankcase

tester and the vacuum pump.

5.2.1 Preparator

steps

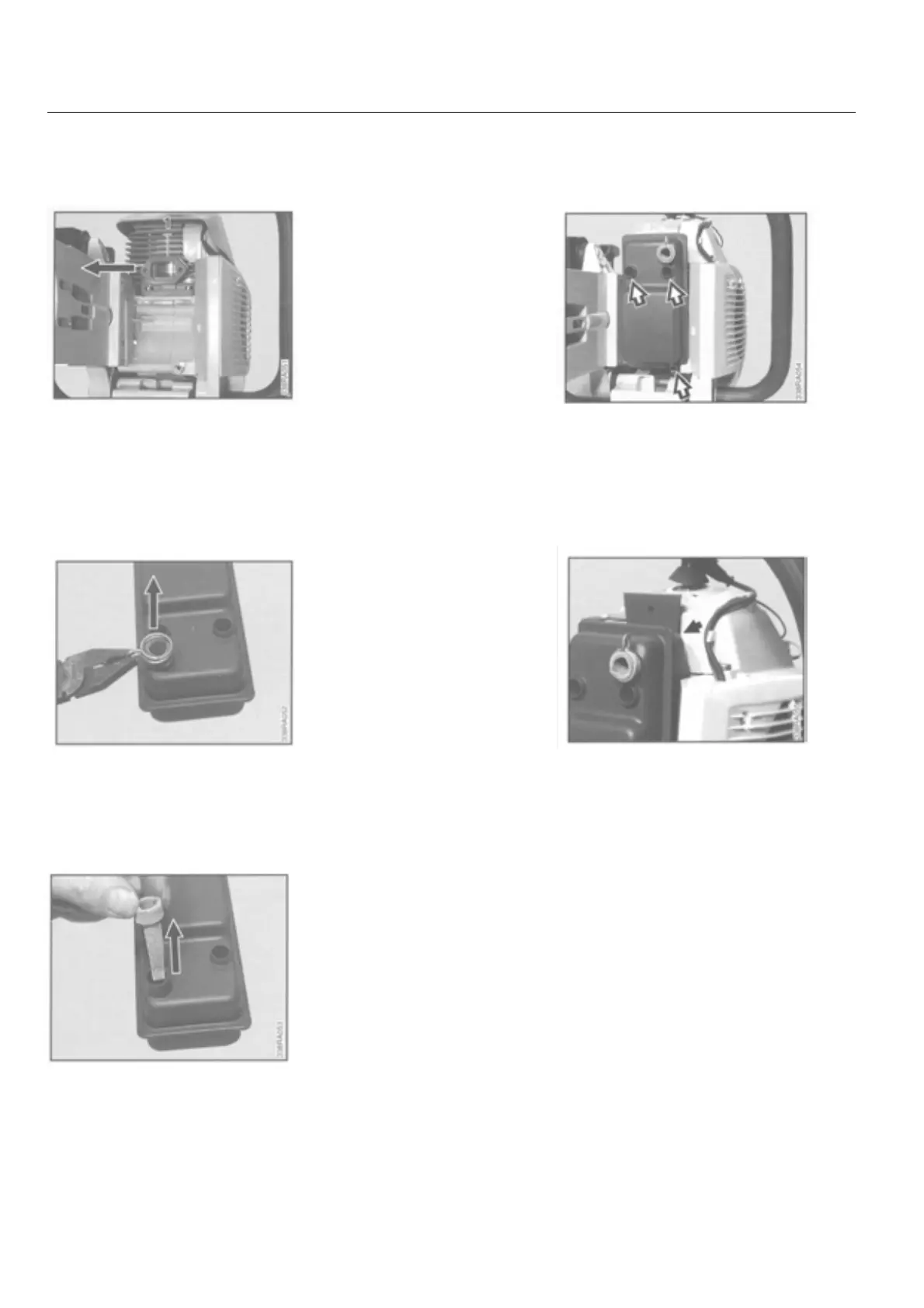

• Draw out the spark arresting

screen.

- Clean the spark arresting

screen; fit new screen if

necessary.

- Remove shroud, see chapter 5.5.

• Unscrew the muffler screws

half-way.

- Remove gasket.

Note: When fitting muffler, position

new gasket so that the bead (1)

points towards the muffler.

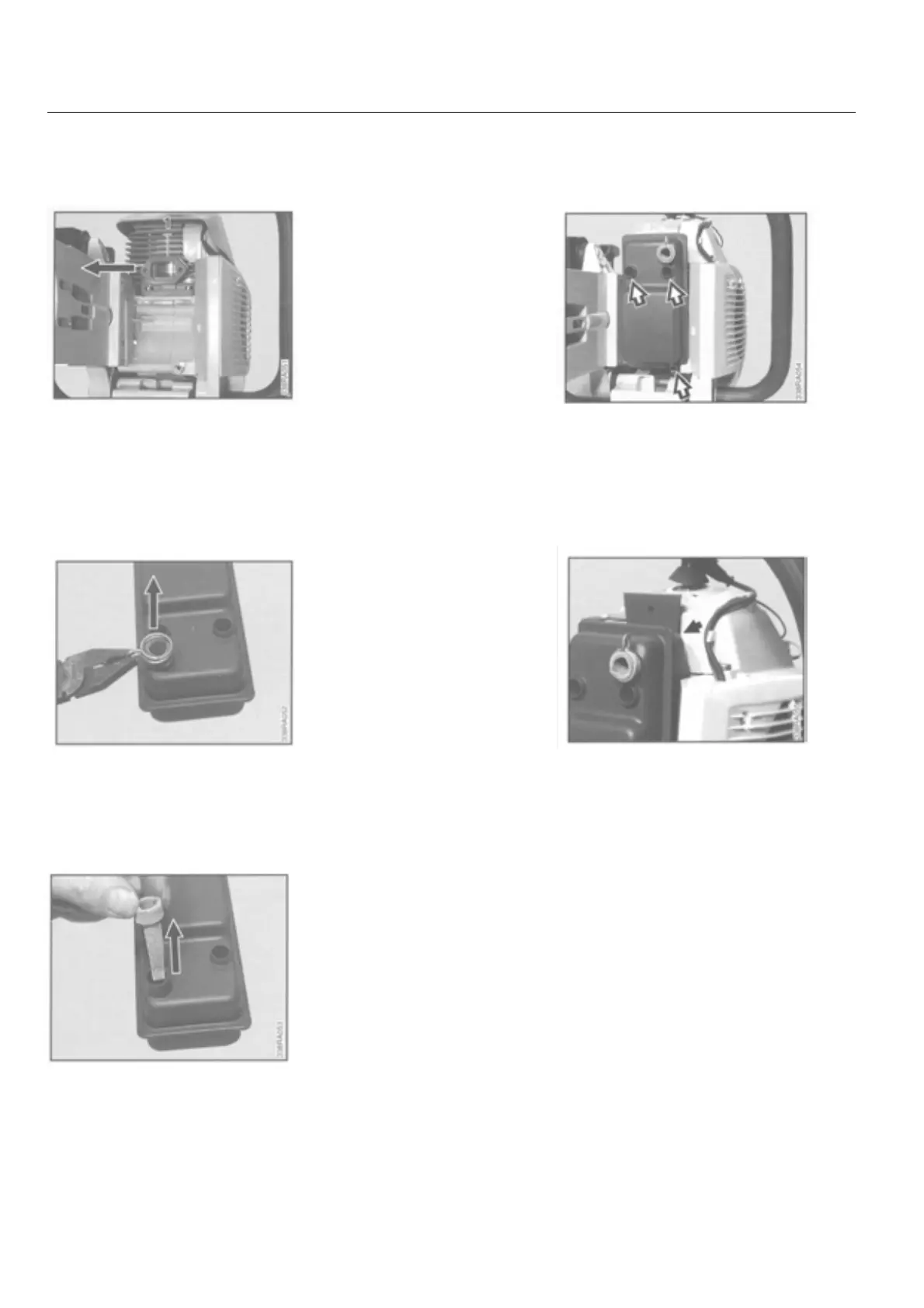

• Slide a sealing plate (1) between

muffler and cylinder exhaust port

and tighten both the upper screws.

Note: The sealing plate must fill the

full width between the screws.

- Remove carburetor,

see chapter 10.3.

- Set piston to upper dead center

(UDC) (can be seen through the

inlet port).

• Compress and remove the clip.

Loading...

Loading...