24

12.08

Strapex STB 63

7 PREVENTIVE AND CORRECTIVE MAINTENANCE

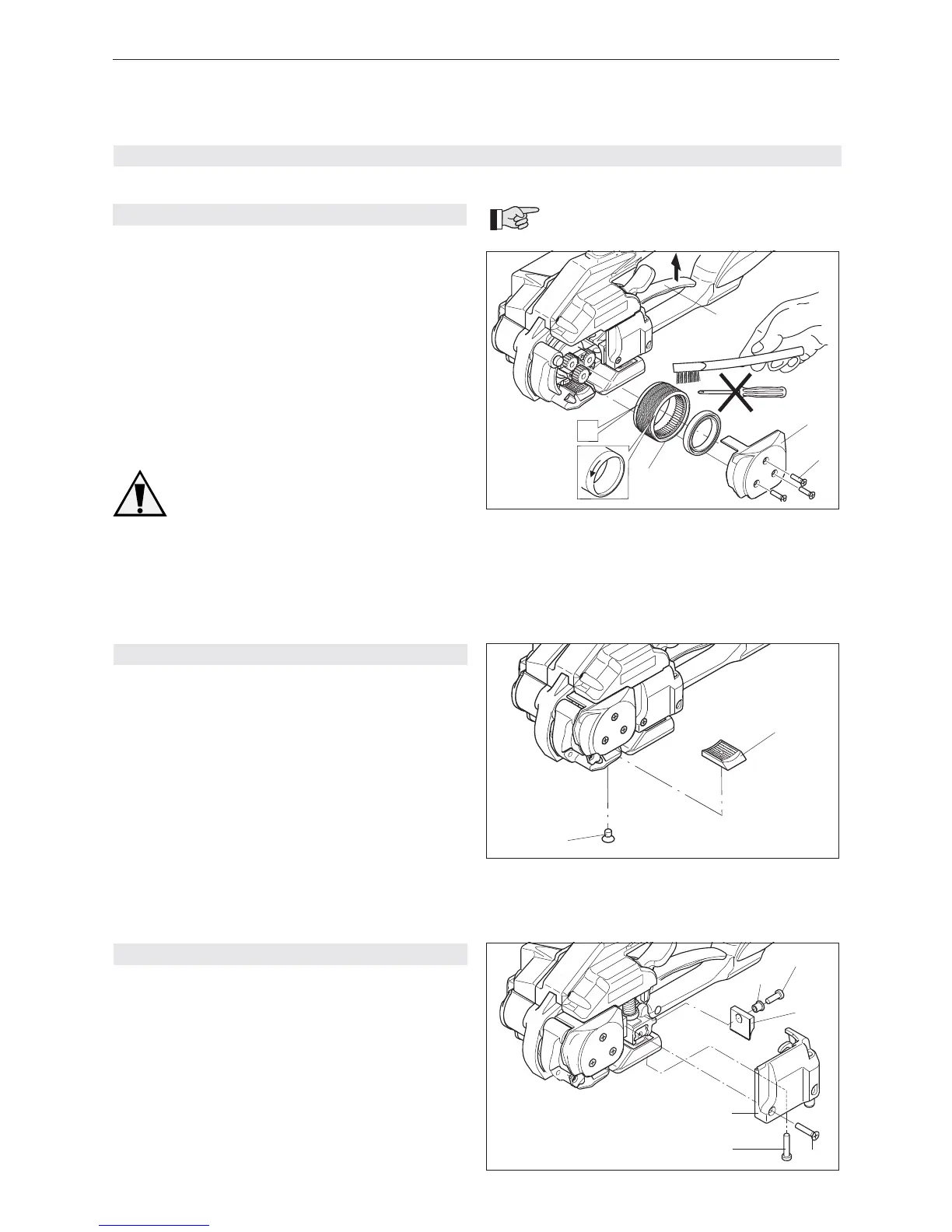

7.1 CLEANING/REPLACING TENSION WHEEL

Removal

– Remove battery from tool.

– Release three sunk screws (20/2) and remove cover

(20/3) with ball bearing.

– Lift rocker lever (20/4) and remove tension wheel

(20/1).

– Clean the tension wheel with compressed air (wear

goggles).

– If the tension wheel teeth are covered with heavy

dirt, they must be carefully cleaned with the wire

brush supplied.

– Check tension wheel for worn teeth. If a few teeth

are broken, replace tension wheel (observe rotating

direction, see arrow)

The tension wheel must not be cleaned

while it is rotating. There is a risk of

breaking teeth!

Installation

– Install the parts in reverse order.

– Grease gear teeth of tension wheel lightly with

Klüber grease GBU Y 131 (Microlube).

– When mounting tension wheel lift rocker lever.

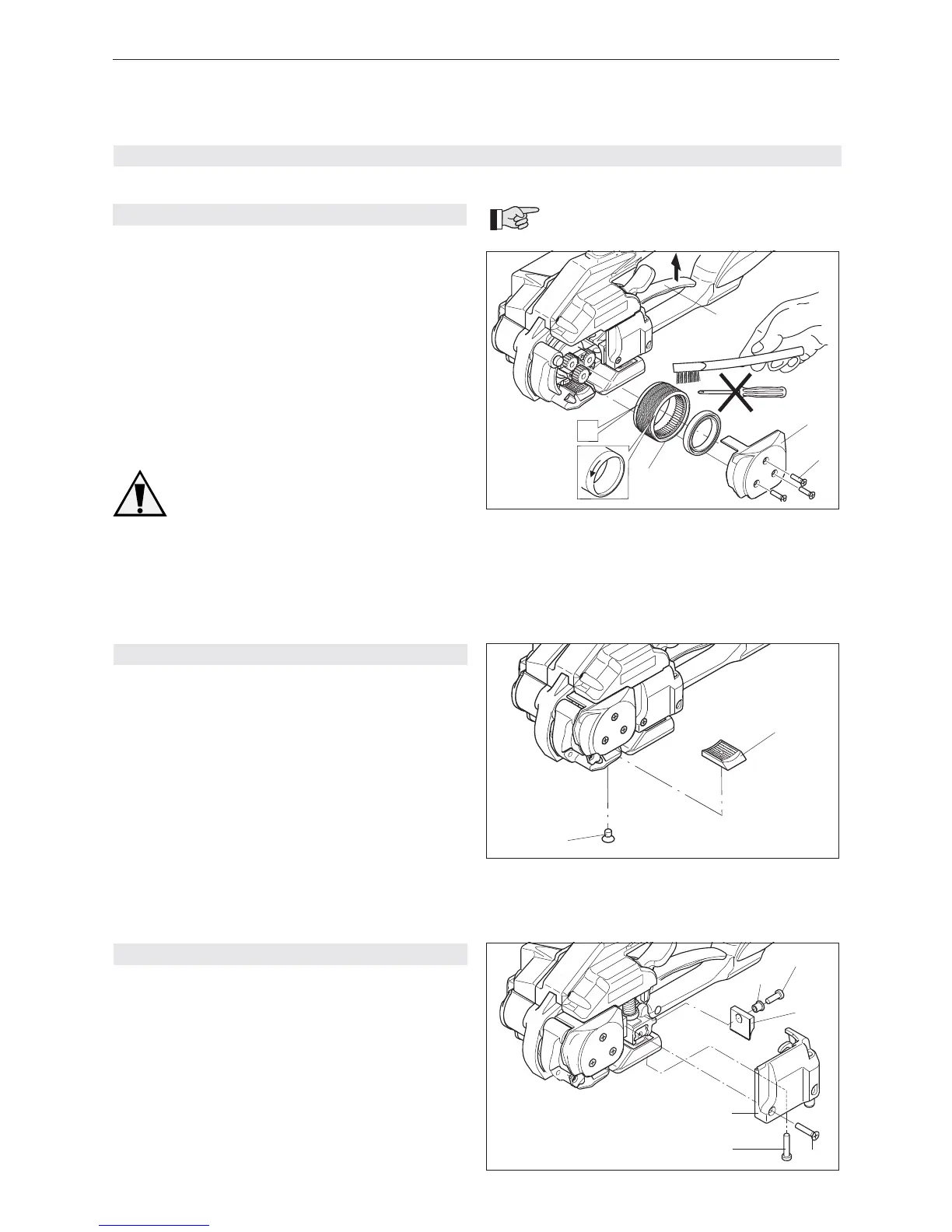

7.2 CLEANING/REPLACING TOOTH PLATE

Removal

– Remove battery from tool.

– Release sunk screw (21/1) and remove tooth plate

(21/2).

– Clean tooth plate with compressed air (wear

goggles).

– If the tooth plate teeth are covered with heavy dirt,

they must be carefully cleaned with the wire brush

supplied or a sharp tool.

– Check tooth plate for worn teeth, if necessary

replace tooth plate.

Installation

– Install the parts in reverse order.

– Secure sunk screw (21/1) with Loctite 222.

7.3 REPLACING CUTTING KNIFE

Removal

– Remove battery from tool.

– Release sunk screw (22/2) and cylinder screw

(22/1) and remove cover (22/3).

– Release cylinder screw (22/6) and remove cutting

knife (22/4) with fl anged bushing (22/5). Replace

cutting knife.

Installation

– Install the parts in reverse order.

– Before install cutting knife, check that the compres-

sing spring on top of knife is still mounted.

– Secure screw (22/1), (22/2) and (22/6) with Loctite

222.

All preventive maintenance tasks can be

performed with a Phillips screw driver!

Fig. 22

1

2

3

4

5

6

Fig. 21

1

2

Fig. 20 (2 = Tension wheel type for STB 63)

2

1

3

2

4

Loading...

Loading...