Section 2

DESCRIPTION

12

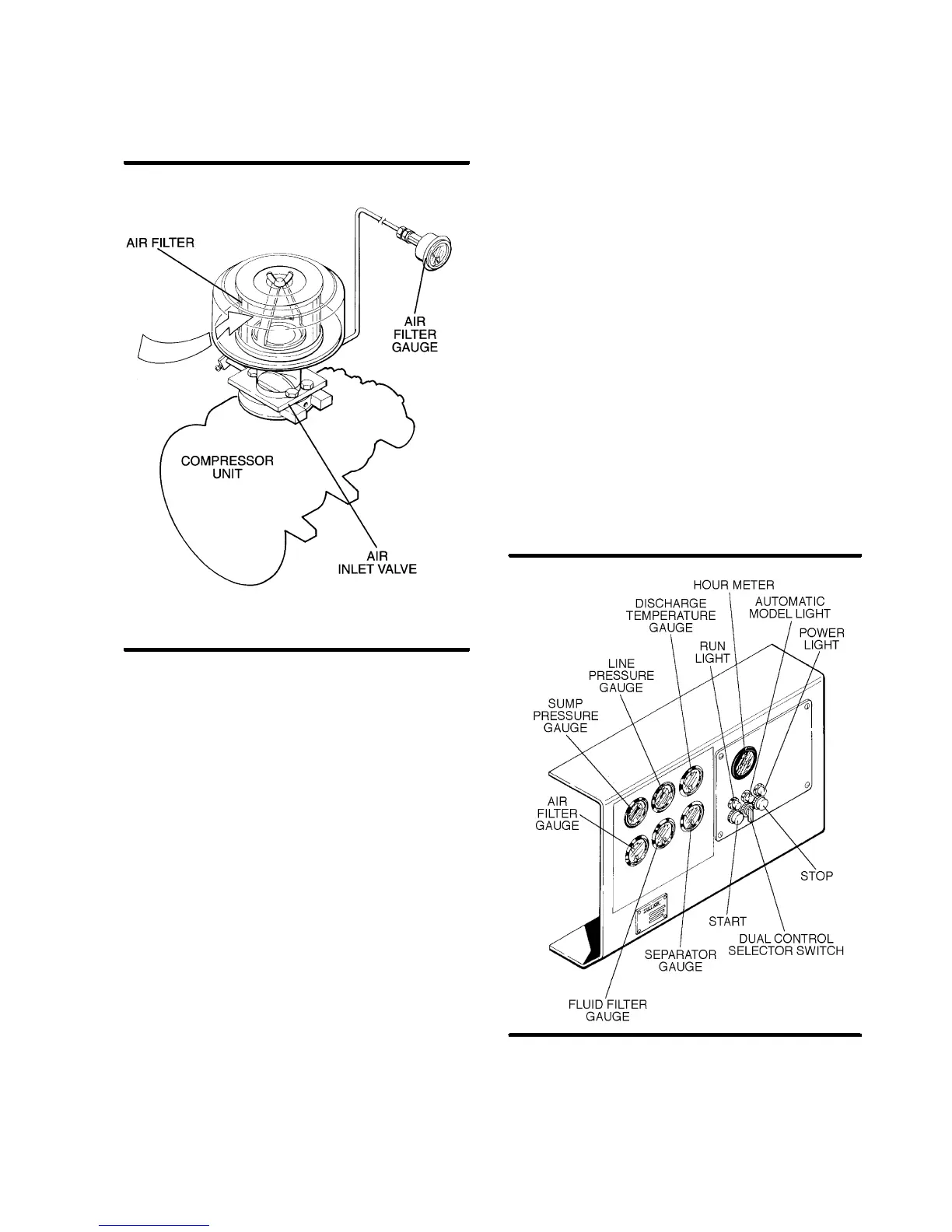

Figure 2---6 Compressor Air Inlet System

restriction gauges

,alongwith

ST ART

and

STOP

pushbuttons and an

hourmeter

.

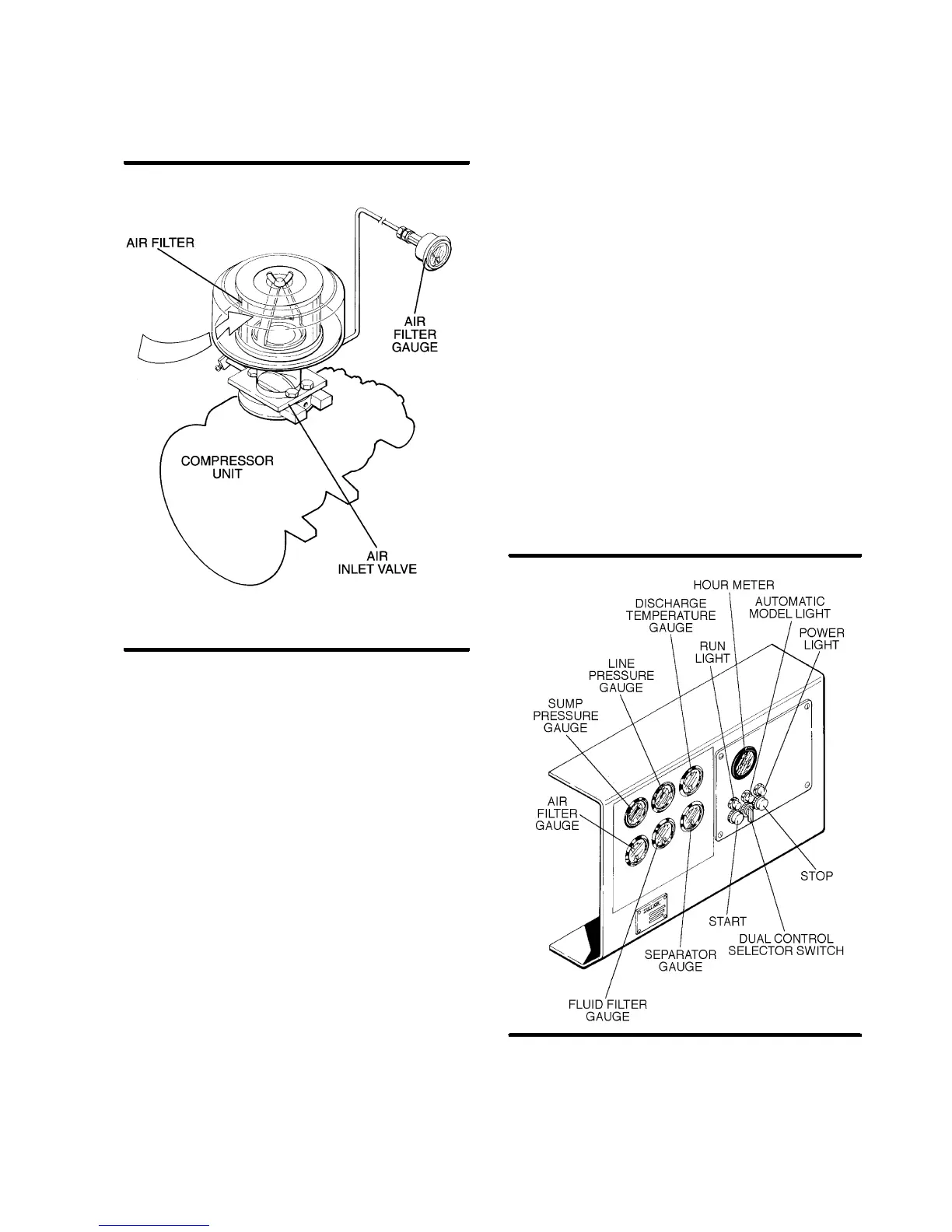

Refer to Figur e 2 --- 7 f or l oc a tions of the fol l owing in -

dicators and controls:

S

and 100HP

The

line (terminal) pressure gauge

is connected to the dry side of the receiver down-

stream from the check valve and continually moni-

tors the air pressure.

S

The

sump pressure gauge

continually monitors

the sump pressure at the various load and/or un-

load conditions.

S

The

discharge temperature gauge

monitors

the temperature of the air leaving the compressor

unit. For both air---cooled and water---cooled com-

pressors the normal reading is approximately

180

_

F(82

_

C) when the ambient temperature is

less than 80

_

F(27

_

C).

S

The

air filter restriction gauge

monitors the con-

dition of the air intake filter and shows in the red

zone(20”to30”water[51to76cm])when filterser-

v ic e is r equir ed ( s ee Figur e 2 --- 6 ) .

S

The

ST ART

pushbutton turns the compressor on.

S

The

STOP

pushbutton turns the compressor off.

S

The

hourmeter

records cumulative hours of op-

eration for the compressor and is useful for plan-

ning and logging service operations.

S

The

separator maintenance gauge

monitors

the condition of the separator elements and shows

in the red zone when the element restriction is ex-

cessive.

S

The

fluid filter maintenance gauge

monitors

the condition of the bearing filter element and

shows in the red zonewhen the element should be

changed.

S

The

red light

on the instrument panel indicates

when power to the compressor is supplied.

S

The

greenlight

indicates whenthe compressor is

running.

S

The optional

dual control package

is supplied

with an amber auto mode indicator light to indicate

that the unit is running in the automatic mode. A

position selector switch provides selection be-

tween hand operation and automatic control.

Figure 2---7 Instrument Panel Group

Loading...

Loading...