Section 6

MAINTENANCE

26

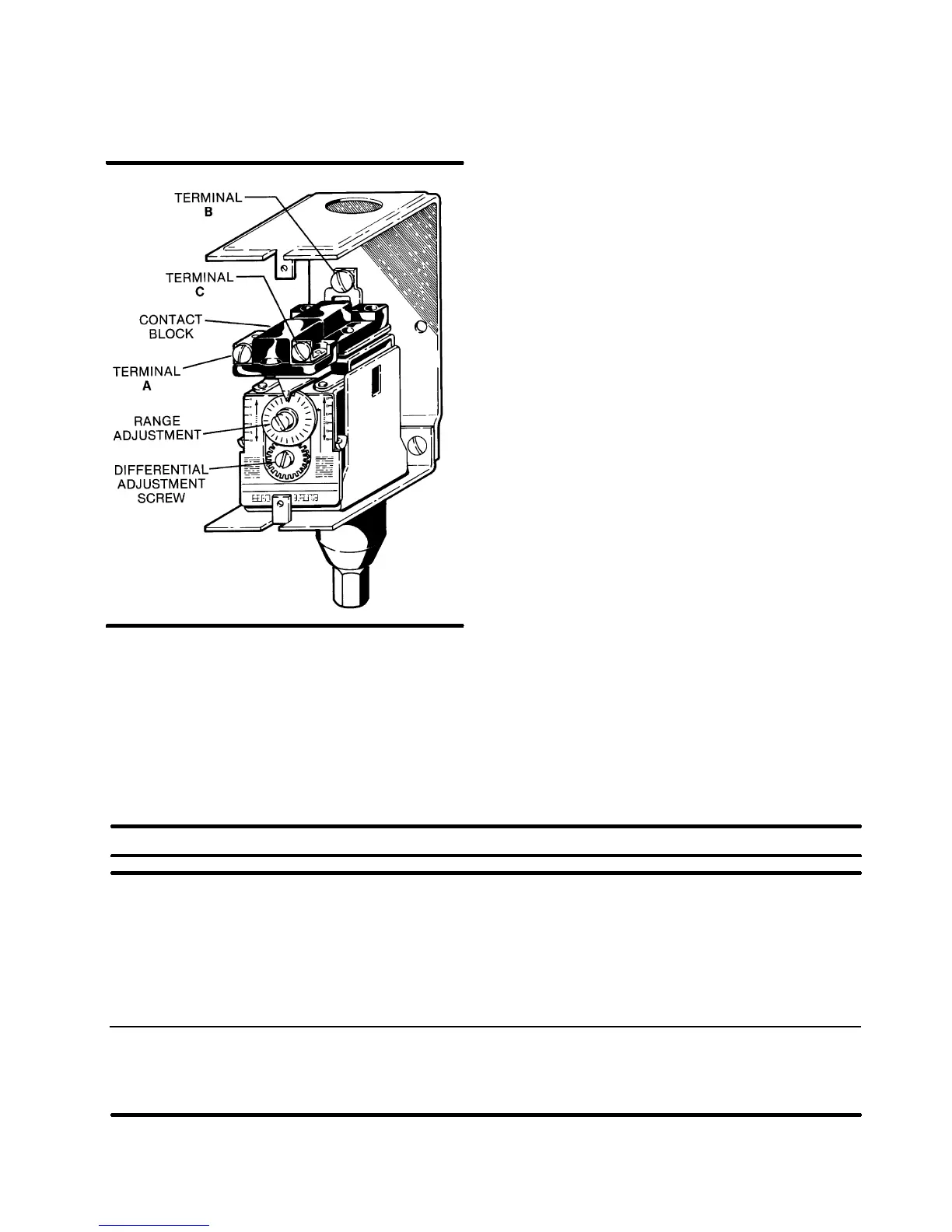

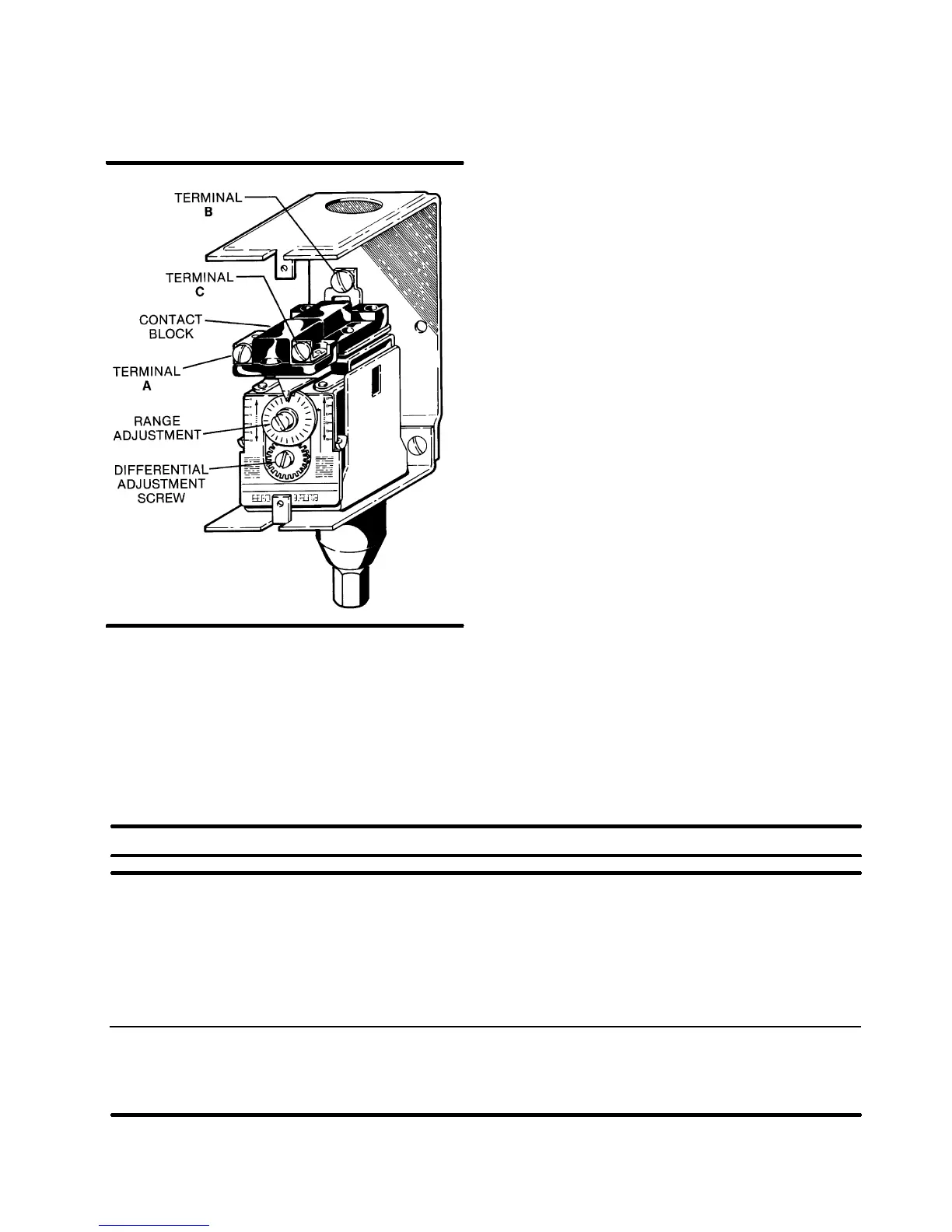

Figure 6---7 Pressure Switch (P/N 040694)

2. Turn the range adjusting screw to the high pres-

sure setting. Turning thescrewcounterclockwise

lowers both the high and low pressure equally.

FOR DIFFERENTIAL ADJUSTMENT:

Differential is the difference between the high and

low pressure settings, 10 psig (0.7 bar) is typical.

Turn the differential adjusting screw tothe lower (re-

set) setting. Turning the screw counterclockwise

widens the differential by lowering the reset (lower)

setting only.

When the pressure switch adjustment is complete,

the pressure regulator should be adjusted for the

pressure at which modulation of air delivery should

begin. In this case, that pressure will be 100 psig

(6.9 bar). The regulator isadjusted by loosening the

jam nut on the end of the cone shaped cover of the

pressure regulator. With the jam nut loose, turn the

adjusting screw clockwise to increase or counter-

clockwise to decrease the setting.

Above 100psig (6.9 bar), the regulator should allow

pressure to flow into the control chamber of the Sul-

licon Control. The Sullicon Control lever should start

to move at this time.

Cycle the control system several times and recheck

all pressure settings.

6.8 TROUBLESHOOTING

The information contained in the Troubleshooting

chart has been compiled from field report data and

factory experience. It contains symptoms and usual

causes for the described problems. However

DO

NOT

assume that these are the only problems that

may occur. All available data concerning thetrouble

should besystematically analyzed before undertak-

ing any repairs or component replacement proce-

dures.

A detailed visual inspection is worth performing for

almost all problems and may avoid unnecessary

additional damage to the compressor. Always re-

member to:

1. Check for loose wiring.

2. Check for damaged piping.

3. Check for parts damaged by heat or an electrical

short circuit, usually apparent by discoloration or

a burnt odor.

Should your problem persist after making the rec-

ommended check, consult your nearest Sullair rep-

resentative or the Sullair Corporation factory .

TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

COMPRESSOR WILL NOT START Main Disconnect Switch Open Close switch.

Line Fuse Blown Replace fuse.

Control Transformer Fuse Blown Replace fuse.

Motor Starter Overloads Tripped Reset. Should trouble persist, check

whether motor starter contacts are

functioning properly.

Low Incoming Line Voltage Check voltage. Should voltage check low,

consult power company.

COMPRESSOR SHUTS DOWN

WITH AIR DEMAND PRESENT Loss of Control Voltage Reset. If trouble persists, check that line

pressure does not exceed maximum oper---

ating pressure of the compressor (specified

on nameplate).

Loading...

Loading...