Section 6

MAINTENANCE

22

6.1 GENERAL

Asyouproceed inreading thissection, itwill beeasy

to see that the Maintenance Program for the air

compressor is quite minimal. The use of the service

indicators provided forthe bearing filter, air filter and

fluid separator, will alert you when service mainte-

nance is required. When the maintenance gauge

shows red, maintenance for that specific item is re-

quir ed. S ee instr u c tions f or eac h item in S ec tion 6 . 7 ,

Parts Replacement and Adjustment Procedures.

6.2 DAILY OPERATION

Prior to starting the compressor, it is necessary to

check the fluid level inthesump. Should the level be

low, simply add the necessary amount. If the addi-

tionoffluid becomes too frequent, asimple problem

has developed which iscausing this excessive loss.

S ee the Tr oubl eshooting S ec tion (6 . 8 ) under Ex c es -

sive Fluid Consumption for a probable cause and

remedy.

After a routine start has been made, observe the in-

strument panel gauges and be sure they monitor

the correct reading for their particular phase of op-

eration. After the compressor has warmed up, it is

recommended that a general check on the overall

compressor and instrument panel be made to as-

sure that the compressor is running properly.

WARNING

!

DO NOT remove caps, plugs, and/or other compo-

nents when compressor is running or pressur-

ized.

Stop compressor and relieveall internalpressure

before doing so.

6.3

MAINTENANCE AFTER INITIAL 50

HOURS OF OPERATION

After the initial 50 hours of operation, a few mainte-

nance requirements areneeded toclean thesystem

ofany foreignmaterials. Performthe following main-

tenance operations to prevent unnecessary prob-

lems.

1. Clean the return line strainers.

2. Clean the return line orifices.

6.4

MAINTENANCE EVERY 4000

HOURS

After 4000 hours ofoperation, it willbe necessary to

perform the following:

1. Clean the return line strainers.

2. Lubricate the Sullicon Control linkage.

3. Replace the fluid filter element and gasket.

4.

ST ANDARD COMPRESSORS ONLY!

Drain the

sump and change the compressor fluid.

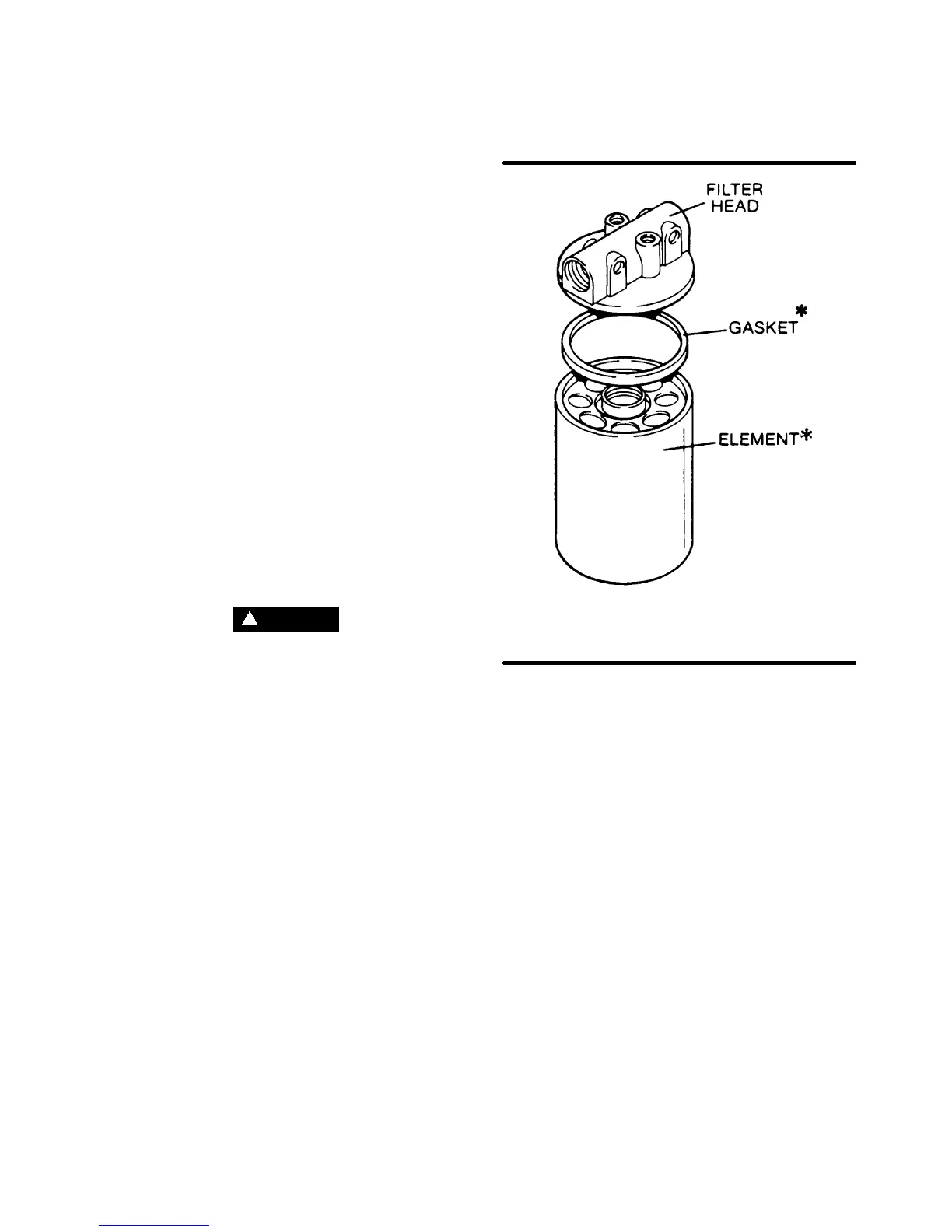

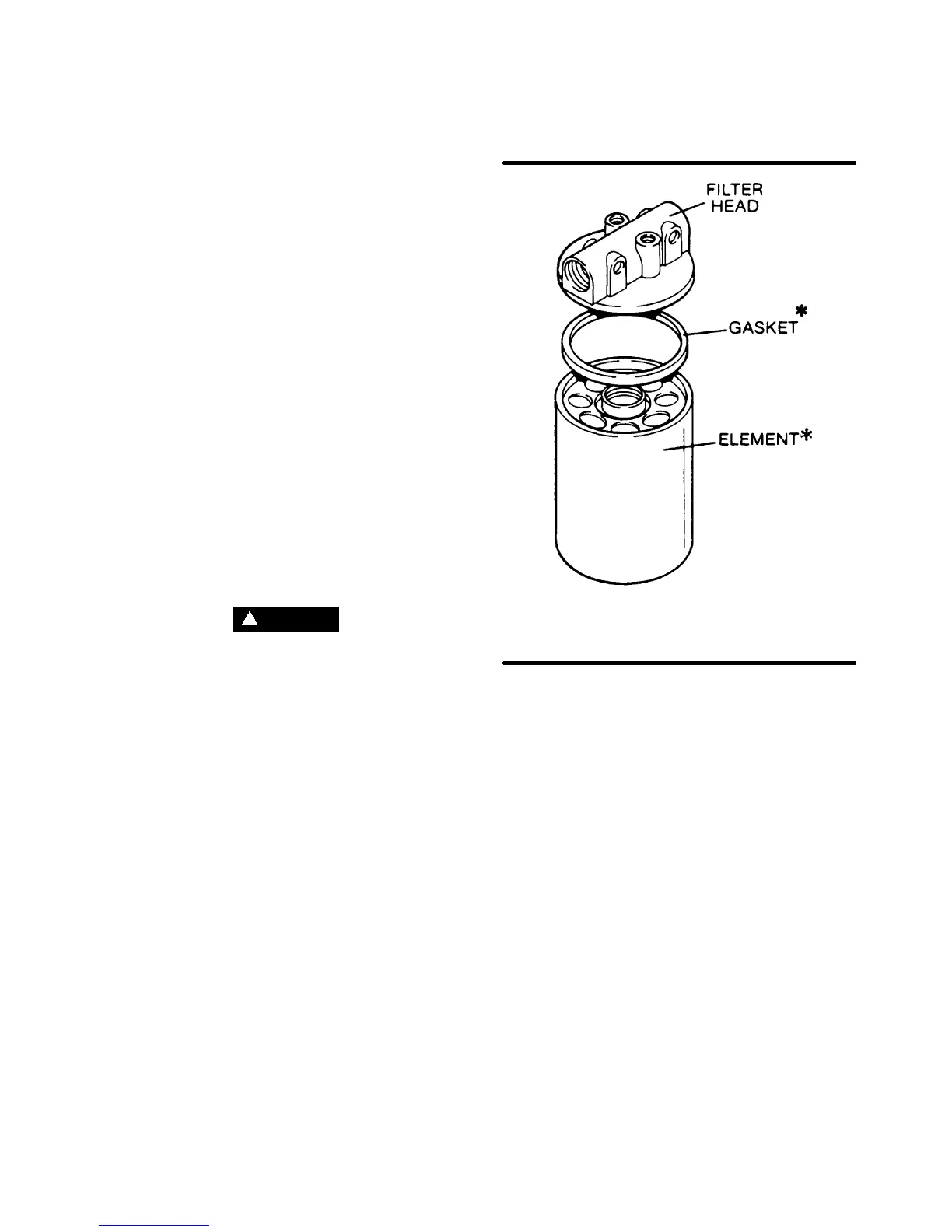

* Repair Kit P/N 250025---526 (40---75HP)

Figure 6---1 Fluid Filter (P/N 250025---522)

Repair Kit P/N 250025---524 (100HP)

6.5 FILTER MAINTENANCE

Replace your fluid filter element and the gasket un-

der any of the following conditions, whichever oc-

curs first:

1. As indicated by the maintenance gauge.

2. Every 1000 hours.

3. Every 6 months.

4.

ST ANDARD COMPRESSORS ONLY!

Every

fluid change.

6.6 SEPARATOR MAINTENANCE

Replace the separator elements when your separa-

tor maintenance gauge shows red or after one (1)

year, whichever comes first. The separator ele-

ments must bereplaced.

DONOT

clean thesepara-

tor elements.

6.7 PARTS REPLACEMENT AND ADJUSTMENT

PROCEDURES

FLUID FILTER ELEMENT REPLACEMENT

R e f e r t o F i g u r e 6 --- 1 .

1. Using a strap wrench, remove the old element

and gasket.

2. Clean gasket seating surface.

3. Apply a light film of fluid to the new gasket.

4. Hand---tighten new element until new gasket is

seated in the gasket groove. Avoid any nicks,

cuts or pinches to the gasket.

Loading...

Loading...