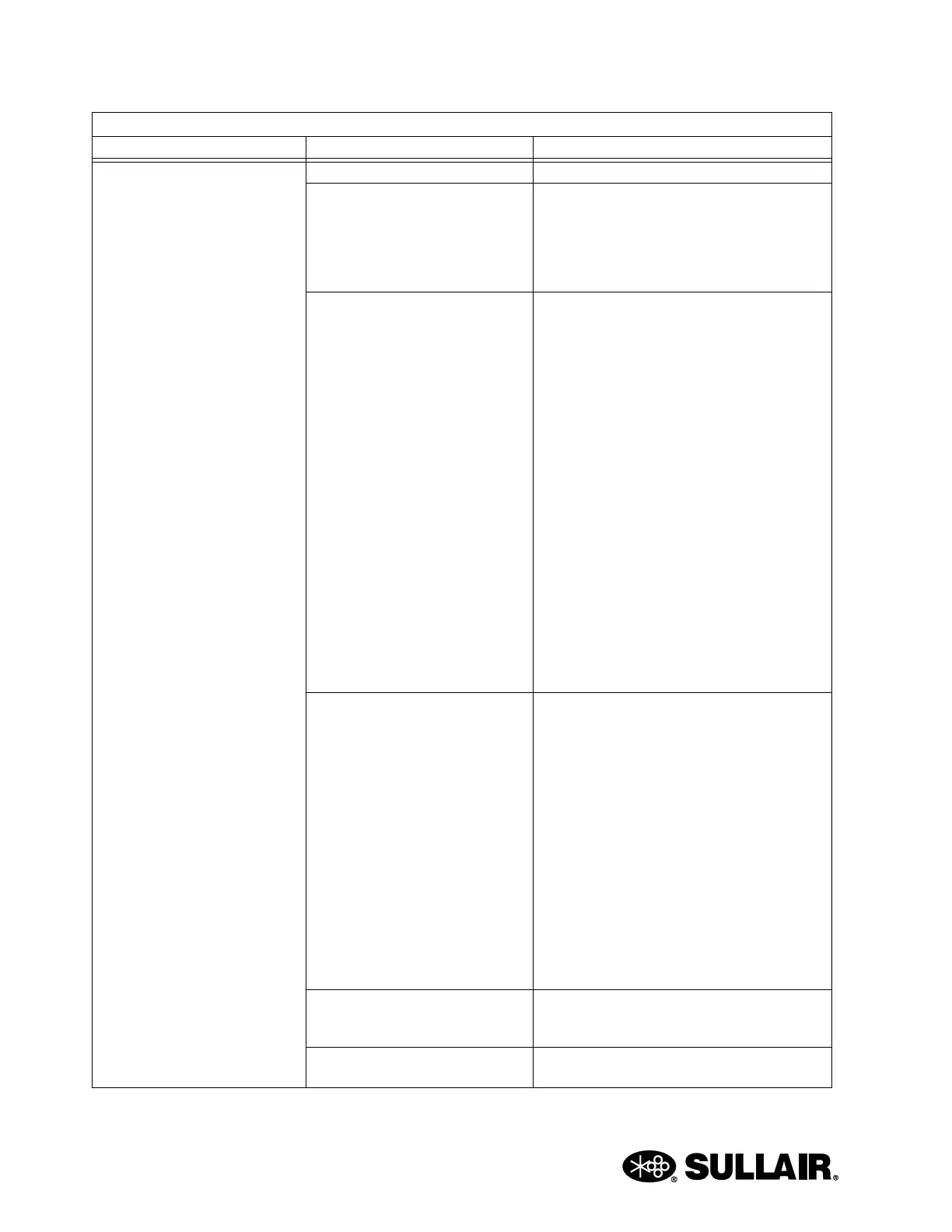

TS20C USER MANUAL SECTION 7

120

Compressor Shuts Down With

Air Demand Present

Loss of control voltage Check incoming power

Low incoming voltage Check control fuses and wiring. Consult power

company. The Sulliar Supervisor™ will provide

indication of most maintenance problems if

control power has not been lost. Shutdowns

will occur upon a faulty condition or a bad

sender condition.

Excessive operating pressure Check maximum P2 pressure setting.

HIGH PRESS P1 display; Max P1 pressure

may be set too low. Consult factory for

recalibration.

Defective solenoid valve; solenoid valve

should cause Sullicon Control lever to move to

unload stop when the unload pressure setting

P2A is exceeded. Repair if defective.

Defective blowdown valve; blowdown valve

should exhaust sump pressure to 30 psig (2.1

bar) for integrated coolers; 50 psig (3.4 bar) for

remote coolers when maximum operating

pressure is reached. Repair if defective.

Open or shorted P1, P2, P3 or P4 sender

message; replace sender indicated.

Operating lever of inlet butterfly valve is loose

on valve shaft. Reposition the valve plate and

tighten lever set screw.

HIGH TEMP T1 or T3 Message

Displayed

Cooling air flow restricted; clean cooler and

check for proper ventilation.

Ambient temperature is too high; provide

sufficient ventilation.

Low fluid level; add fluid.

Clogged fluid filter; change the fluid filter

element as indicated by Supervisor™ control.

Thermal valve not functioning properly; replace

element.

Open or shorted T1 or T2 sender; check for a

short or open circuit to probe and correct

wiring.

Low fluid pressure (LOW

PRESSURE P3 DISPLAY)

Check fluid level.

Check for clogged fluid filter.

Cooling fan motor (FAN OL

display)

Check the cooling fan motor.

Table 7-1: Troubleshooting Guide

SYMPTOM PROBABLE CAUSE REMEDY

Loading...

Loading...