10 Installation, Operating and Maintenance Instructions (Original Instructions)

VMS Vertical Multistage Pumps

10

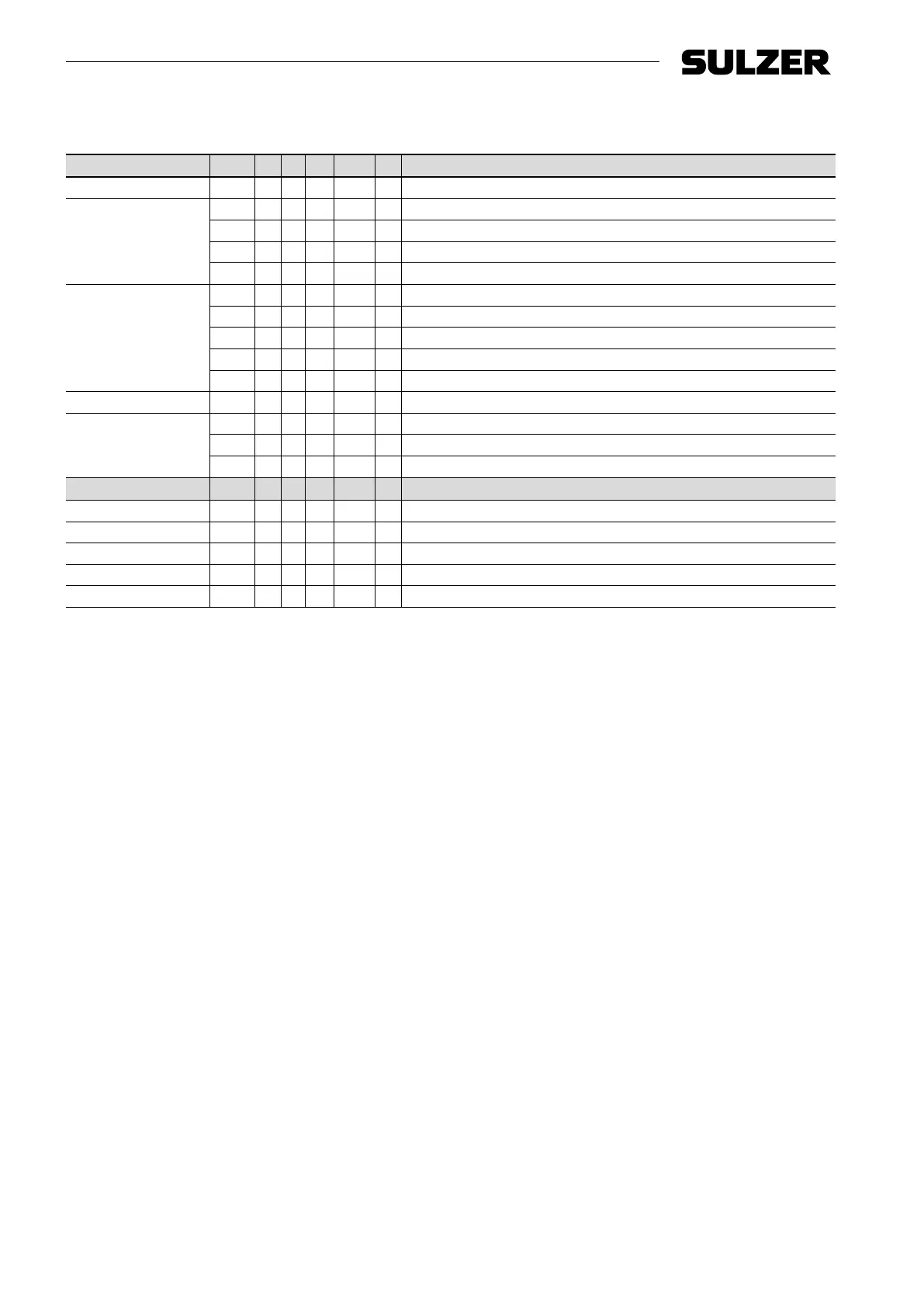

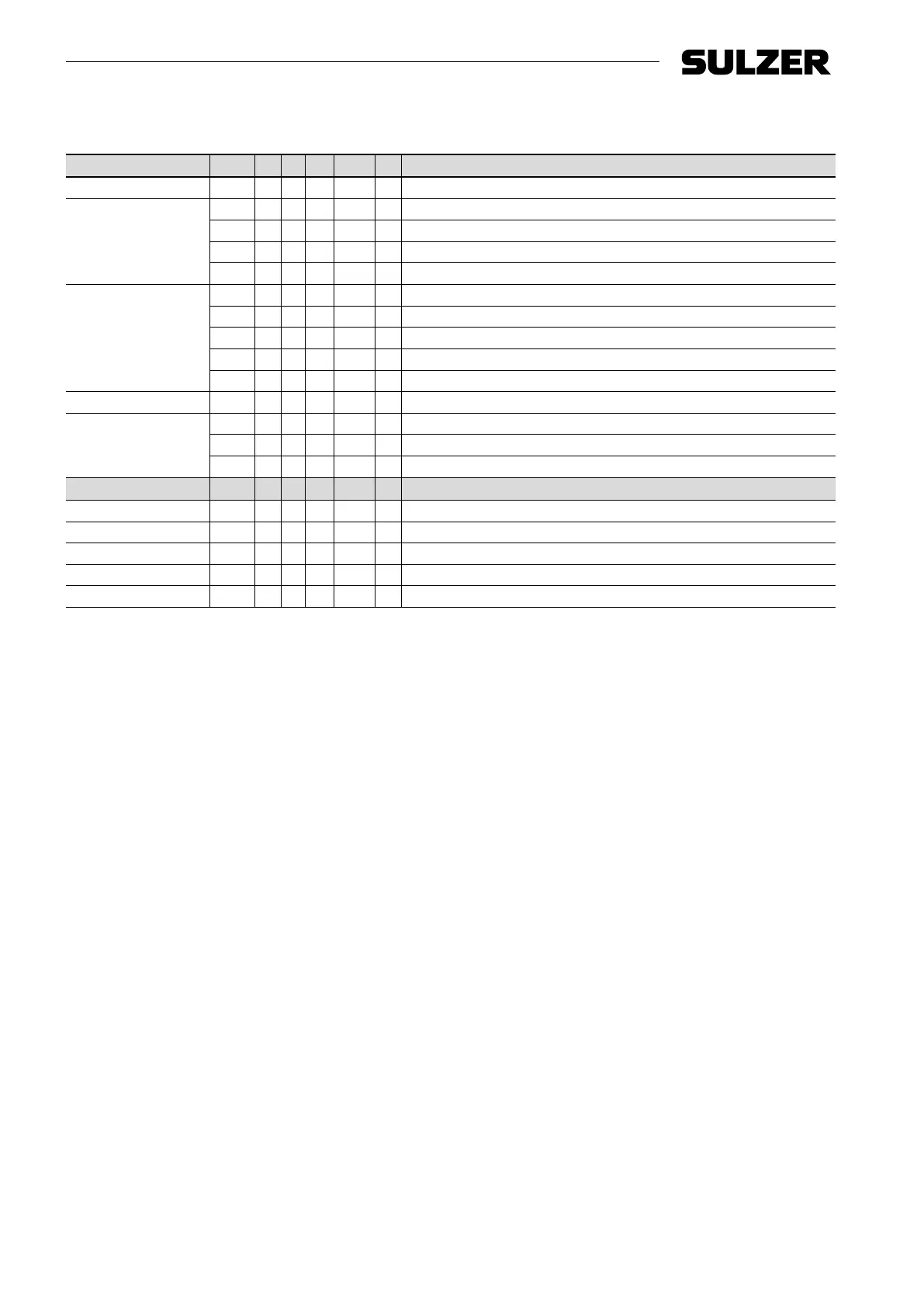

5.2 Model key

Table 4. Model key example

VMS S F 40 /10 -L

Label VMS Product label

Material / Construction C Cast iron pump foot and top bracket hydraulics; 1.4301 / AISI 304

All wetted parts; stainless steel 1.4301 / AISI 304

M All wetted parts;stainless steel 1.4301 / AISI 304 with closed coupled motor

S All wetted parts; stainless steel 1.4401 / AISI 316

Connections E Male thread (with non-return valve insert)

Oval ange with female thread

F Round ange

V Victaulic connections

T Tri-clamp connections

Size 40 Size (capacity in m

3

/h at Q

opt

)

Stages /10 Number of stages

/10 -2 Number of stages of which one stage with reduced head

/10 -L Number of stages of which the rst stage has a “Low NPSHr” impeller

VMS H 6 -200

Label VMS

H Vertical pump in superior grade AISI 316 (1.4401) 40 Bar

Connections Round anges DIN or ASME

6 Size (capacity in m

3

/h at Q

opt

)

-200 Number of stages (x10)

5.3 Ecodesign

Product information according to Regulation 547/2012 and Directive 2009/125/EC ”Ecodesign Directive” (water

pumps with maximum shaft power rating of 150 kW, applies only to water pumps marked with the Minimum

Eciency Index MEI, see pump nameplate):

• Minimum Eciency Index: see nameplate, legend for nameplate. See Table 1, “Nameplate description”.

• The reference value MEI of a water pump with the best eciency is 0.70.

• Year built: see nameplate, legend for nameplate. See Table1, “Nameplate description”.

• Manufacturer’s name or trademark, ocial registration number and place of production: See manual or order

documentation.

• Information about type and size of the item: see Table 1, “Nameplate description”.

• Performance curves of the pump, including eciency characteristics: see documented curve.

• The eciency of a pump with a corrected impeller is usually lower than that of a pump impeller with a full

diameter. A pump with a corrected impeller is adapted to a certain duty point, thereby reducing the energy

consumption. Minimum Eciency Index (MEI) refers to the full impeller diameter.

• The operation of this water pump at dierent operating points can be more ecient and more economical

when it is controlled, for example using a variable speed controller which adjusts the pump operation to the

system.

• Information for disassembly, recycling or disposal after the nal shutdown: see sub chapter 4.5.2,

“Dismantling”.

• Information about the eciency reference value or MEI = 0.7 (0.4) benchmark index for the pump on the basis

of the pattern in the picture, please visit: http://www.europump.org/eciencycharts.

5.4 Intended use

VMS pumps are suited for the transport and increase of pressure of cold and hot water without wear to parts

when used within the indicated working range. The transport of liquids with a dierent viscosity or density than

water is possible as well. Please take into account the possible adjusted motor power which might be required

for this. Ask Sulzer or your distributor for advice.

Loading...

Loading...