Installation, Operating and Maintenance Instructions (Original Instructions) 11

VMS Vertical Multistage Pumps

11

Any other or further use of the pump is not in conformity with its intended use. Sulzer does not accept any

liability for any damage or injury that results from this. The pump is produced in accordance with the current

standards and guidelines. Use the pump only in a perfect technical state, in conformance with the intended use

described below.

The ”intended use” as laid down in ISO 12100:2010 is the use for which the technical product is intended

according to the specications of the manufacturer. The use of the product has been described in the sales

brochure and in the user manual. Always observe the instructions given in the user manual. When in doubt the

product must be used as becomes evident from its construction, version and function.

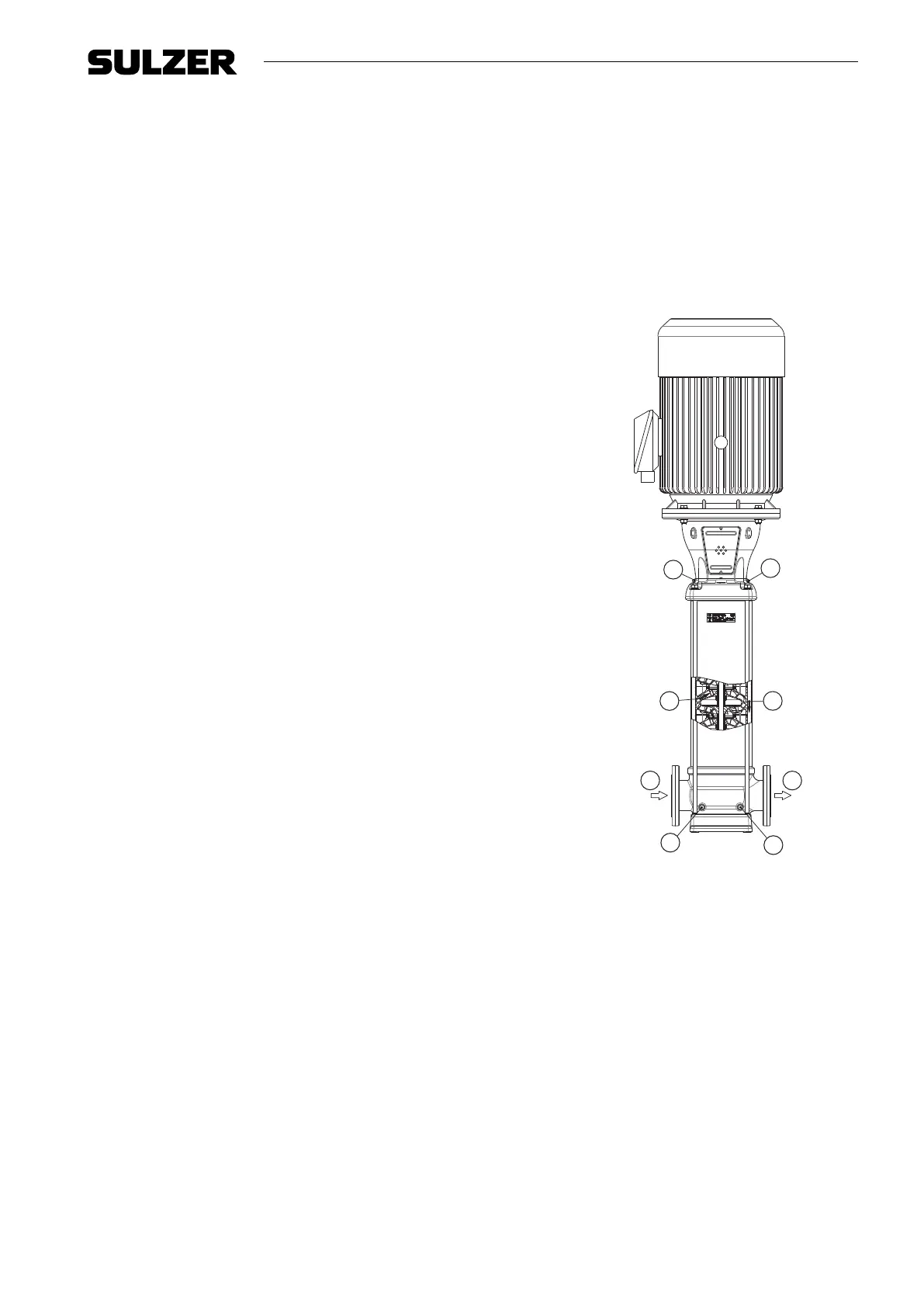

5.5 Operation

The rotating impeller causes the pressure at the inlet of the impeller to

drop. This decrease in pressure creates the ow through the suction

connection (A). Every stage (B) consists of an impeller and a diusor.

The capacity of the pump is determined by the size of the passageway of

the stage. The pressure of the stage is determined by the diameter of the

impeller.

Because of the modular type of construction it is possible to choose the

number of impellers most suited to the required duty point. After leaving

the last impeller the medium ows between the pump stages and the outer

sleeve (C), and exits the pump at the discharge connection (D).

5.6 Measuring, draining and venting

The pump is provided with plugs for measuring, draining and venting.

Connection (E) is meant to drain the inlet part of the pump, or to measure

the inlet / suction pressure using a G ¼" connection.

Connection (F) is meant to drain the outlet part of the pump, or to measure

the discharge pressure using a G ¼" connection.

Connections (G) are meant to vent the pump system when the pump is not

in operation, or to measure the discharge pressure of the pump using a

G

3

/8" connection.

D

A

E

F

G

G

B

C

1561-00

Figure 4. VMSF 85

5.7 Modular selection

For an optimal match with the application, the pump is assembled out of modules which are selected depending

on their specications.

The basic modules are:

• Basic pump model: denes the capacity and head, the basic material and allowable pressures and

temperatures.

• Connections: denes the connection size, pressure class and allowable temperatures.

• Sealings: denes material of the elastomers, shaft seal type and allowable pressures and temperatures.

• Electric motor: denes all requirements of the motor such as size, power, supply voltage, frequency and

possible motor accessories.

Loading...

Loading...