24 Installation, Operating and Maintenance Instructions (Original Instructions)

VMS Vertical Multistage Pumps

24

7.4 Commissioning

Thepumpmustbeswitchedowhenitisnotcompletelylledup.

ATTENTION! Vent the pump and suction line. Fill the pump and suction line with the medium.

ATTENTION! Seen from the top of the motor the pump should rotate clockwise. See § 7.1.1,

Indicators (B). In case of a 3-phase motor the rotating direction can be changed by

exchanging two of the three phases.

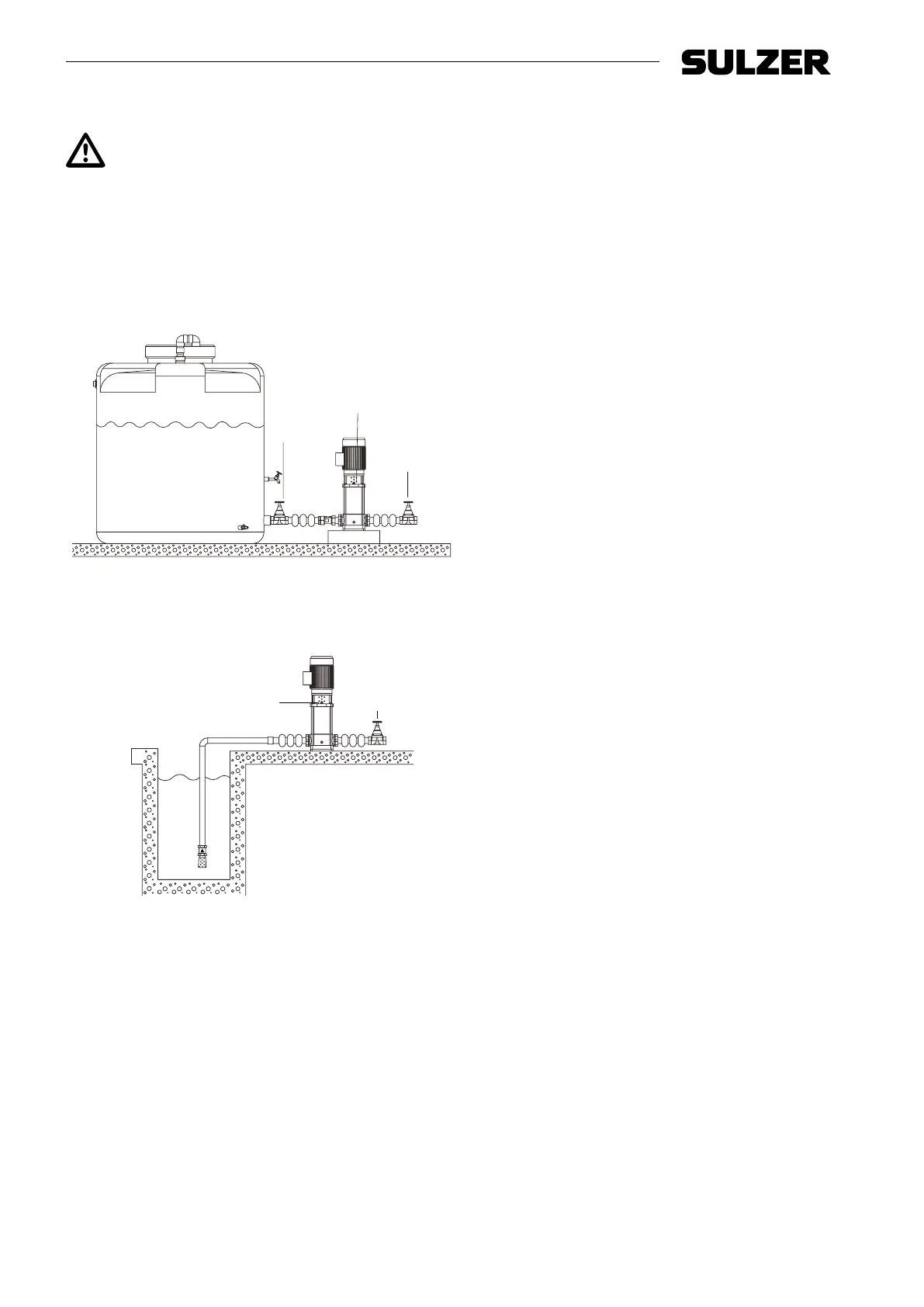

7.4.1 Inanopenorclosedcircuitwithsucientsupplypressure

B

C

A

1572-00

1. Close the suction shut-o valve (C) and

the outlet shut-o valve (A).

2. Open the ll plug (B).

3. Gradually open the suction shut-o valve

until the liquid ows from the ll plug (B).

4. Close the ll plug.

5. Fully open the suction shut-o valve.

6. Check the rotational direction of the pump.

7. Fully open the outlet shut-o valve (A).

Figure 15. Example: pump with open or closed circuit

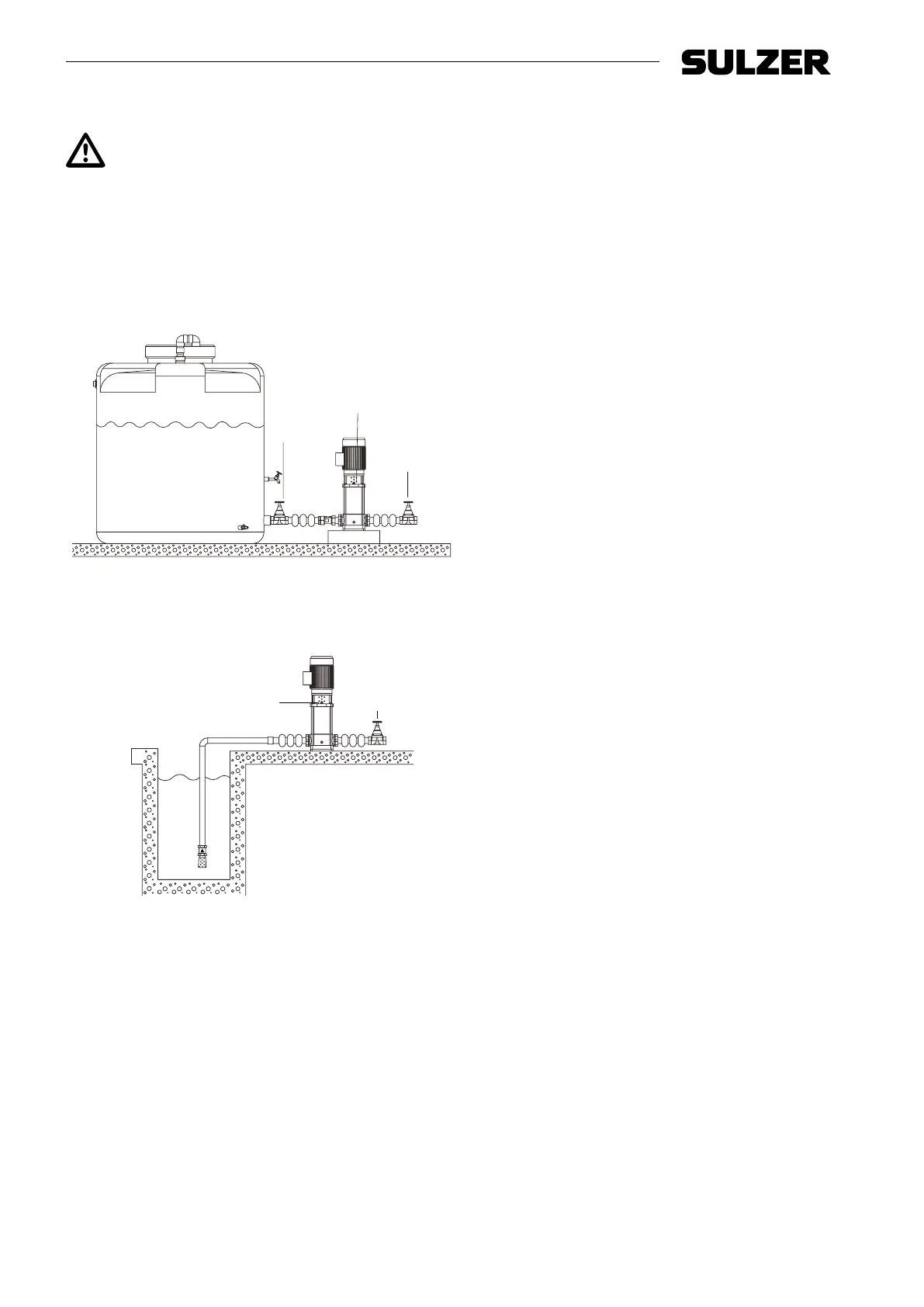

7.4.2 In an open circuit with a liquid level lower than the pump

A

B

1573-00

1. Remove the ll plug (B) from the top

bracket.

2. Close the outlet shut-o valve (A).

3. Fill the pump housing to the maximum

through the ll plug with the liquid that is to

be pumped.

4. Insert the ll plug (B) in the top bracket.

5. Check the rotational direction of the pump.

6. Open the outlet shut-o valve (A).

Figure 16. Example: liquid level lower than pump

7.4.3 After an extended period of non-operation or storage

During rst start-up, check the mechanical seals for leakage due to seizure or dehydration of the lubricating

lm. If so, please proceed as follows:

1. Turn shaft manually.

2. Check if the mechanical seal is still leaking.

If the mechanical seal is still leaking:

1. Disassemble the mechanical seal.

2. Thoroughly clean and degrease the running surfaces.

3. Assemble the mechanical seal again and retry start-up.

If this doesn’t solve the shaft leakage, replacement of the mechanical seal is necessary.

Loading...

Loading...