44

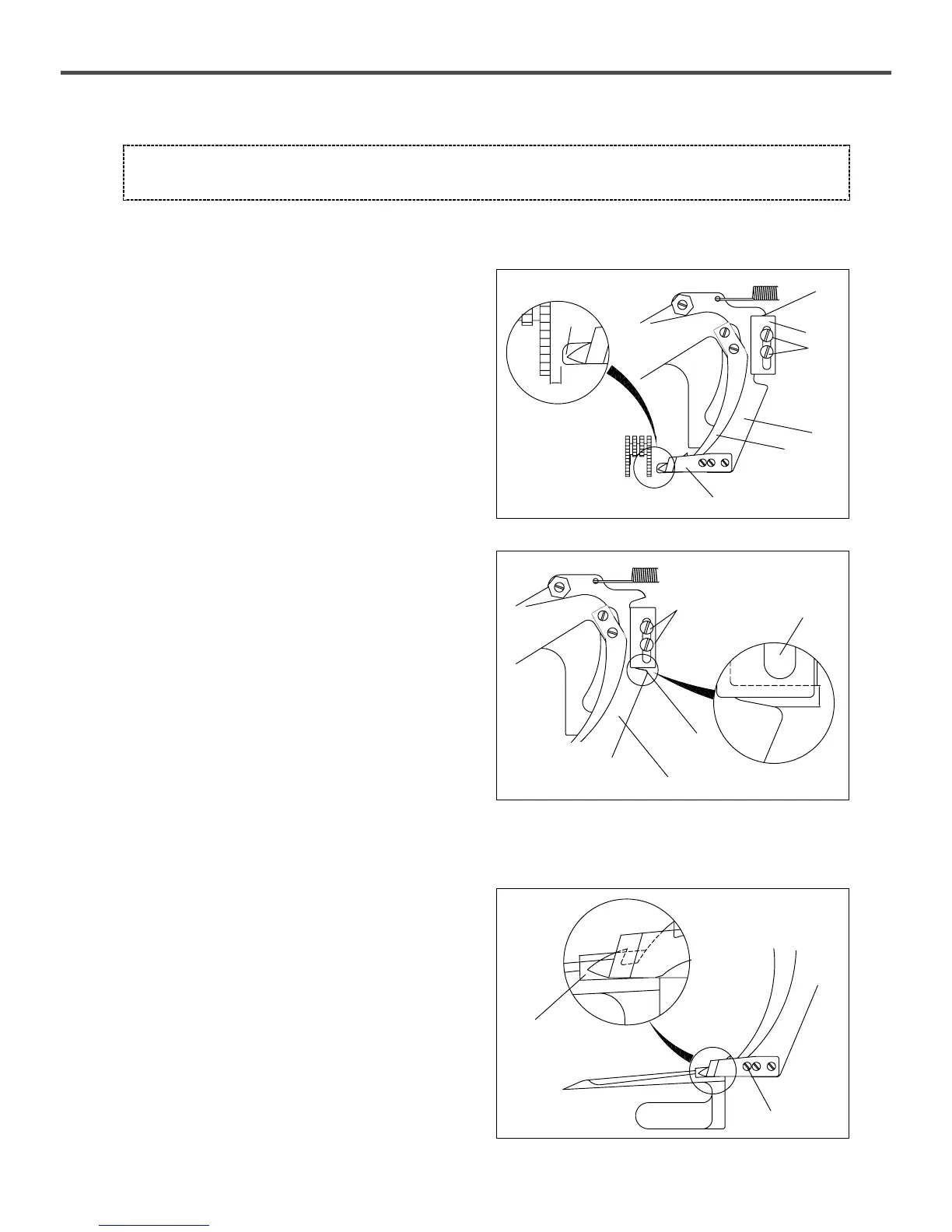

When the trimming device is in motion, the moving mes

① moves to the left and the fixed mes body④ moves to

the furthest left of the moving mes return spring.

When the distance between the tip of the clamp spring②

and the feed dog on the right side is 0~0.5mm, fasten the

screw⑦ to attach the fixed mes stopper(L)⑤ to a part of

the fixed mes body⑥.

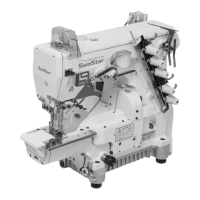

The moving mes① returns from the furthest left along

with the needle thread and the looper thread.

Then it is overlapped with the fixed mes③. The meses

cut the needle thread and the looper thread.

Until the threads are cut off completely, the clamp spring

② should be 0~0.5mm away from the feed dog. This

position determines the length of the remaining thread

after sewing is finished.

· To make the remaining thread shorter, locate the

clamp spring on the left side.

· To make the remaining thread longer, locate the

clamp spring on the right side.

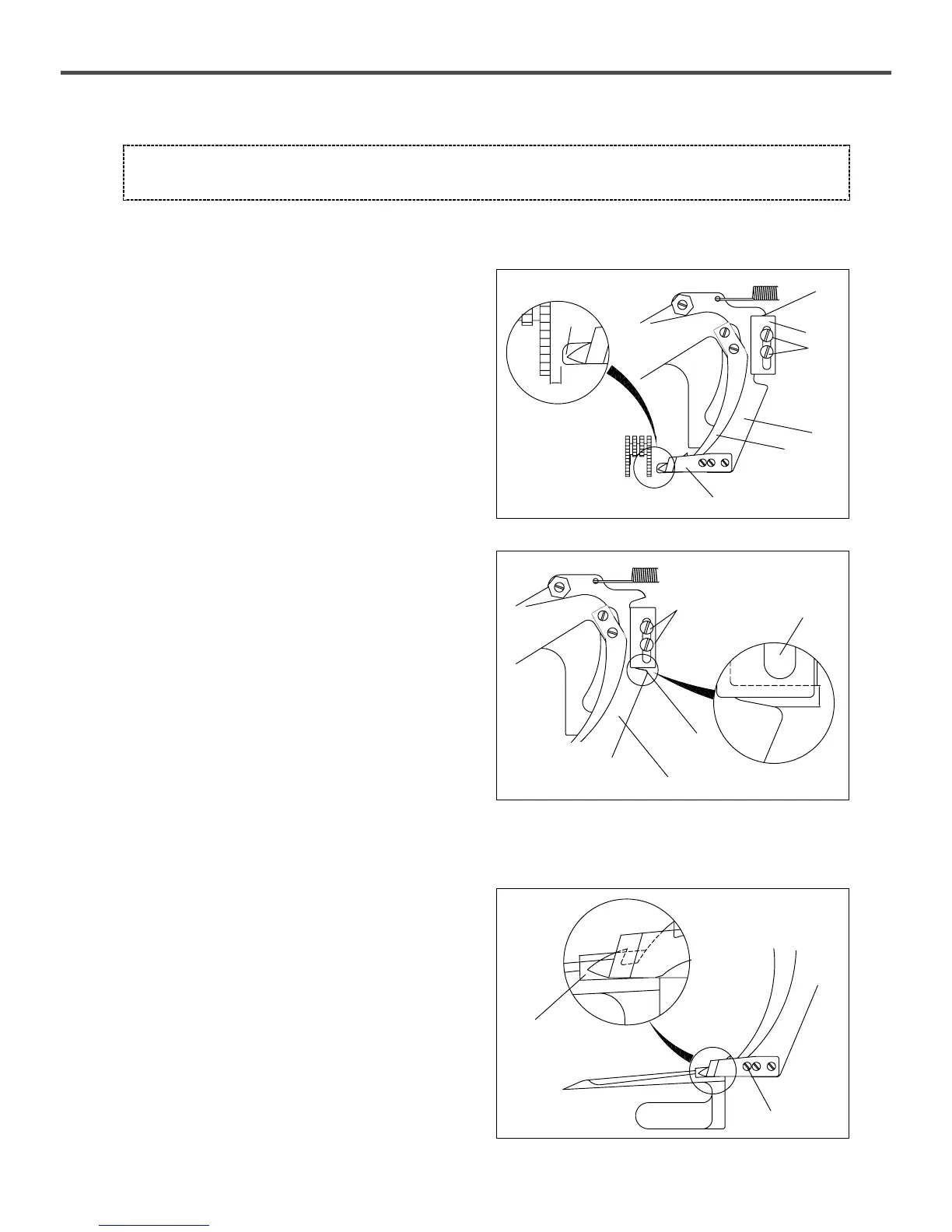

When the plunger of the cylinder is on the left side,

adjust the distance between the blade⑩ of the fixed mes

body⑧ and the fixed mes stopper(small)⑪ at

1.5~2.0mm. (If the trimming device doesn’t operate)

Loosen the screw⑨ for adjustment.

(7) Adjustment of Remaining Thread After Sewing Is Finished

[ Figure 82 ]

[ Figure 83 ]

0~0.5mm

1.5~

2.0mm

④

⑤

⑦

⑪

⑨

⑩

⑧

①

③

②

⑥

The clamp spring holds the looper thread after it cuts the

looper thread. Loosen the screw⑫ for pressure

adjustment.

· To increase pressure, turn the screw clockwise.

· To reduce pressure, turn the screw counter-clockwise.

Maintain pressure at the smallest level as long as the

clamp spring can hold the looper thread.

(8) Adjustment of Clamp Spring Pressure

[ Figure 84 ]

②

⑫

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

Loading...

Loading...