43

[ Warning ]

Before adjustments, always turn off the motor switch and check to make sure that the motor is in stop mode.

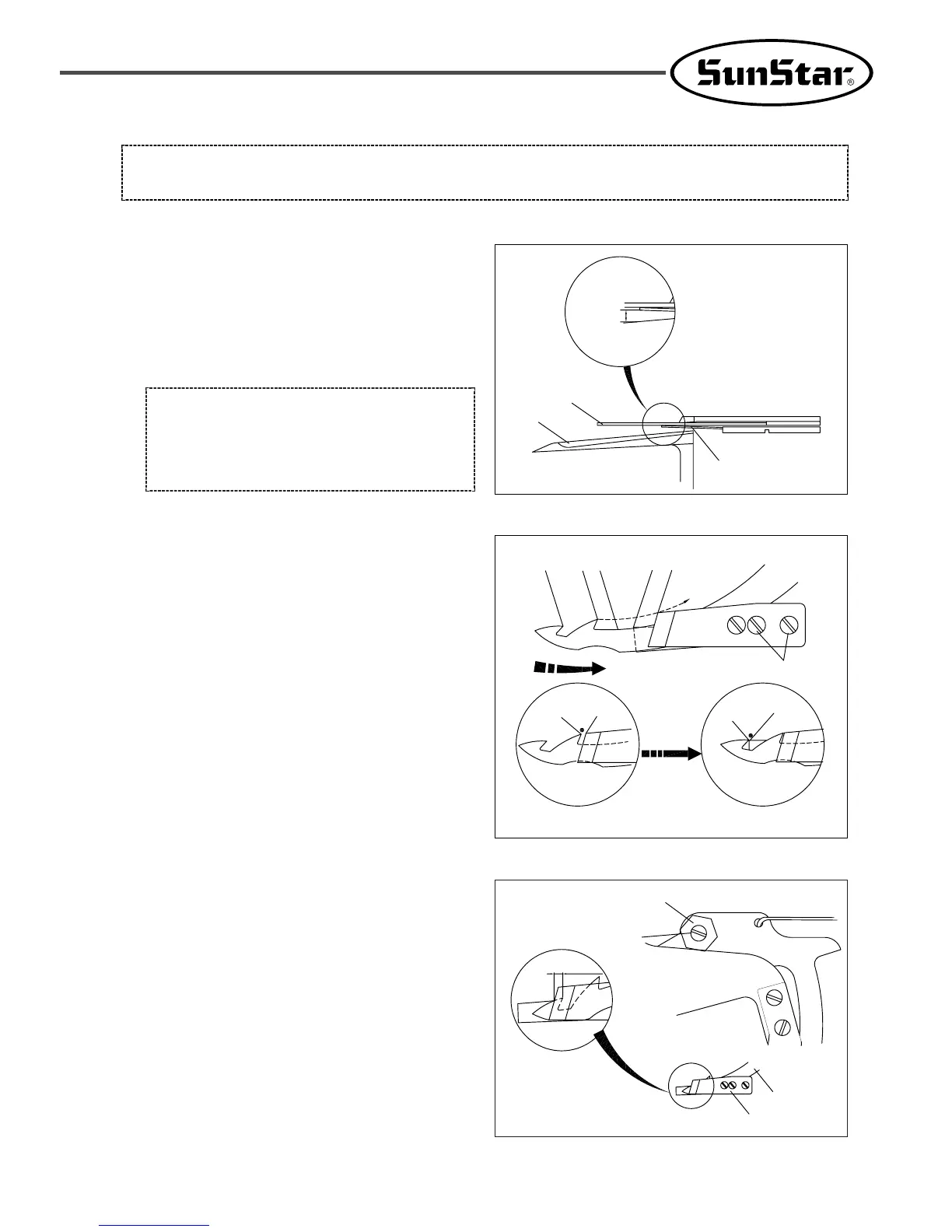

When the moving mes① is in motion, the front face of

the looper② should be 0.1~0.3mm distant from the rear

face of the clamp spring③.

If the distance is inappropriate, the fixed mes might be

bent.

If it happens, please straighten it out. .

(4) Adjustment of Moving Mes and Looper

[ Figure 79 ]

②

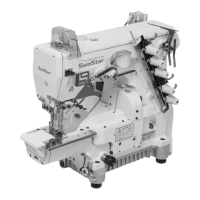

To make the tip of the hook for needle thread④ pass by

the rim⑤(I) of the fixed mes, adjust the tip of the hook

for looper thread⑥ to pass by the rim⑦ of the clamp

spring. And adjust the inner side of the moving mes to

pass by the rim⑦ of the clamp spring.

Loosen the screw⑨ for adjustment.

(5) Adjustment of Moving Mes, Fixed Mes and Clamp Spring

[ Figure 80 ]

④

④

⑤

ⅠⅠ ⅡⅡ

⑤

⑥

⑥

⑧

⑦

⑦

⑨

③

①

0.1~

0.3mm

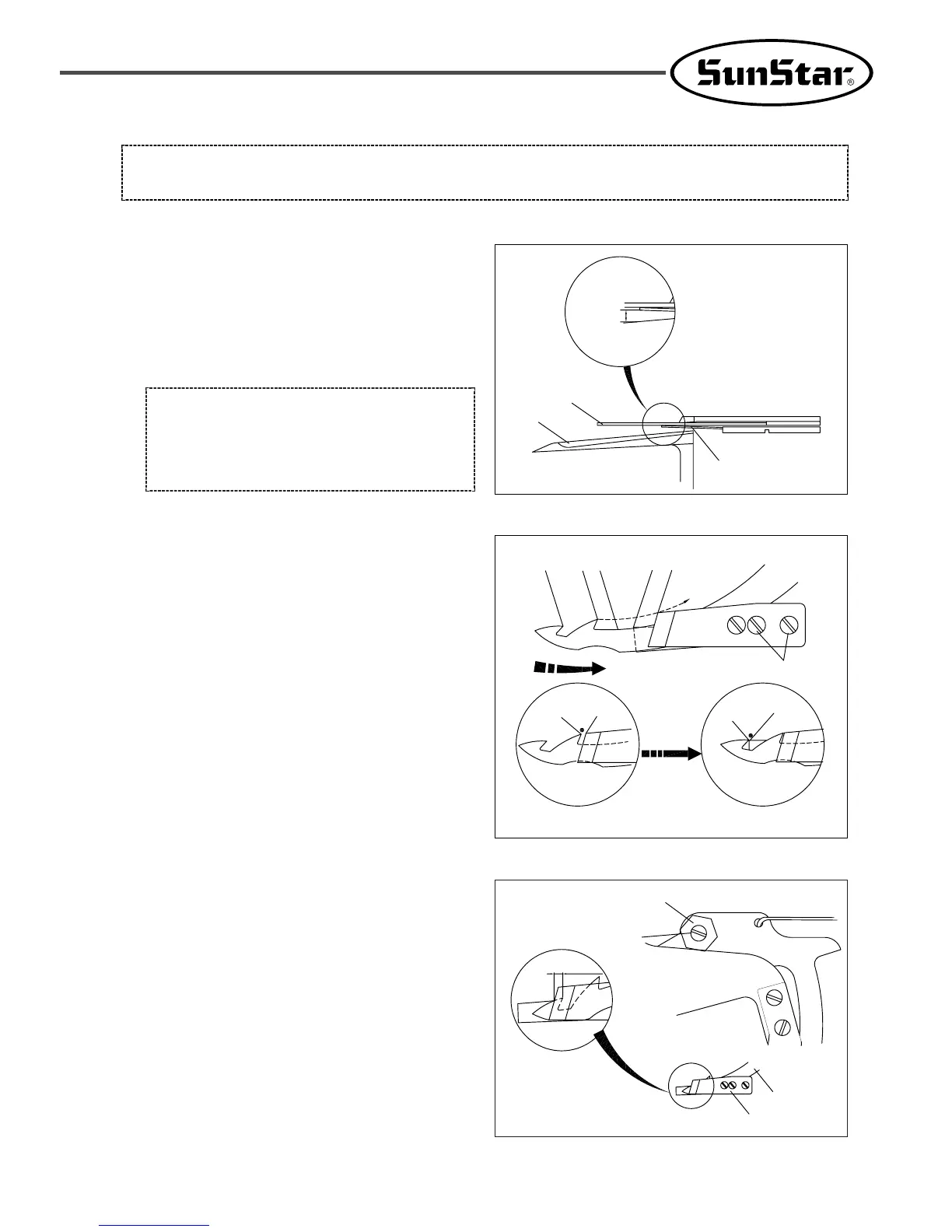

The fixed mes⑪ and the moving mes⑩ overlap around

0.2~0.5mm.

When the moving mes moves to the right in full, loosen

the screw⑬ and move the hexagonal stopper plate⑫ for

overlap adjustment.

(6) Overlapping of Moving Mes and Fixed Mes

[ Figure 81 ]

⑪

⑩

⑬

⑫

0.2~0.5mm

[ Caution ]

When adjusting the distance, don’t make any

changes in the height of the looper.

Any change in the height of the looper might cause

stitch skips.

Loading...

Loading...