28

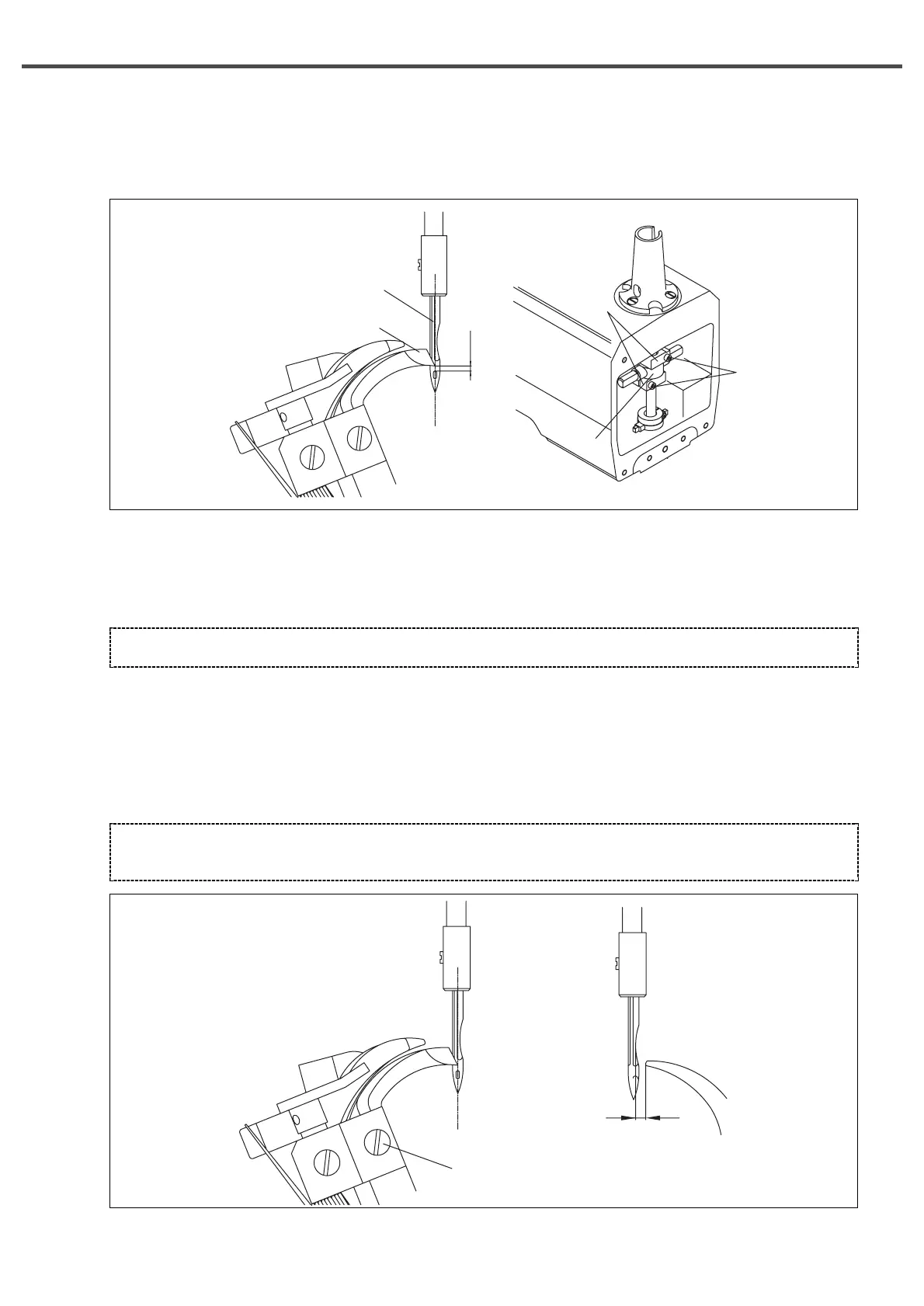

4) Adjust the height of needle bar

A. When the needle① is within the sewing zone, adjust the center of the needle and the end of the looper (left)② to meet

together.

B. Release the screw④ of the needle bar clamp③ and adjust the height of the needle bar.

C. Make adjustment to enable the needle bar clamp③ and the needle bar horizontal link⑤ to maintain their own oil layers

respectively.

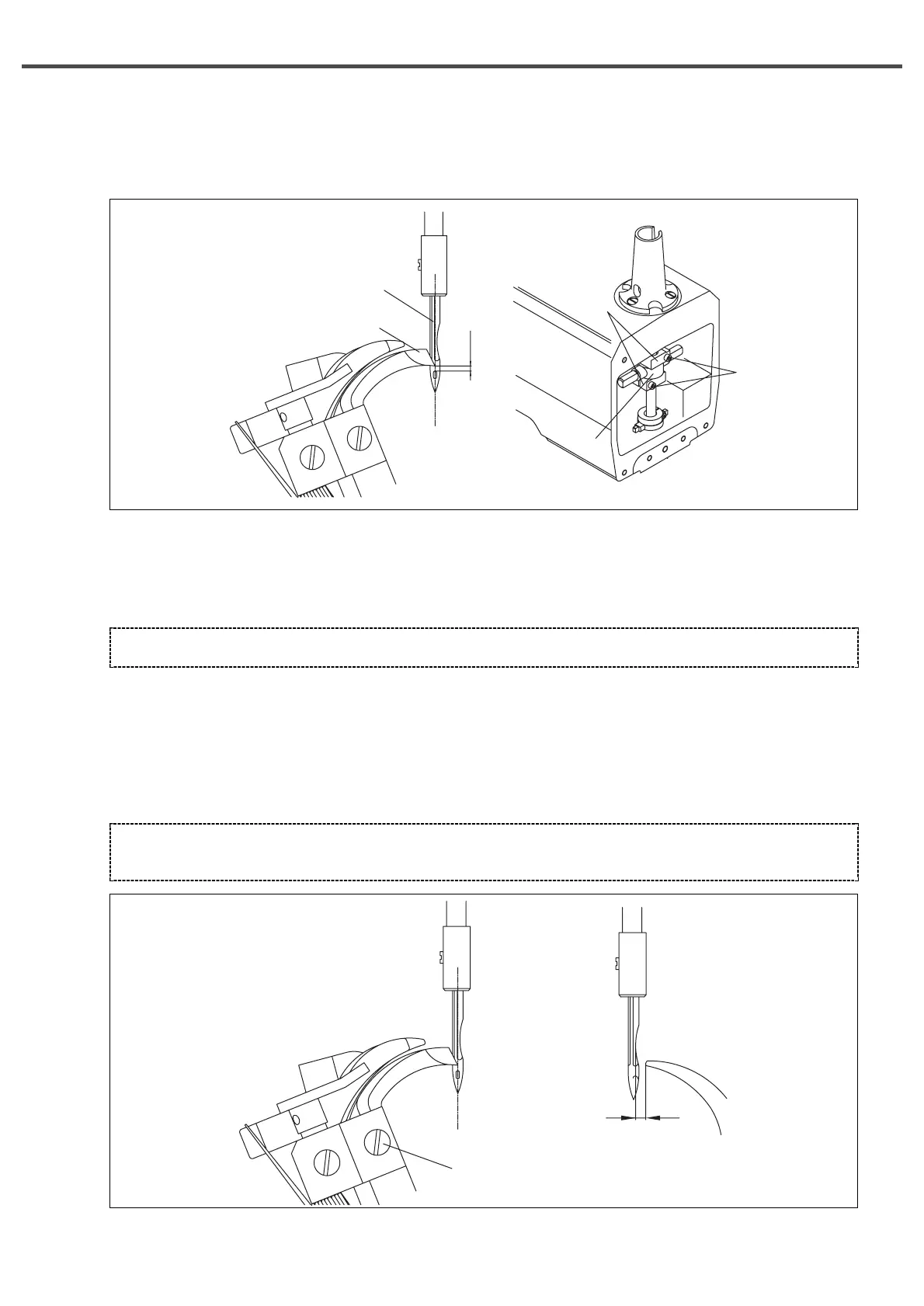

5) Adjust the distance between needle and looper

Loosen the looper screw① to adjust the distance between needle and looper at the range of 0.05~0.2mm, and then tighten the

screw① again.

[ Fig. 31 ]

[ Fig. 32 ]

Make the end of the looper (left)② meet the upper edge of the needle hole and lower the needle bar by 2mm.

[ CAUTION ]

Although the looper base turns 360°, the distance between needle and looper should be same.

①

③

④

⑤

①

0.05~0.2mm

②

2mm

Loading...

Loading...