10

Before every shift or 8-hour operation, check loosened, twisted, hardened, or cracked cable

and wire.

Before every shift or 8-hour operation, check lost or damaged connectors.

Before operation, tighten, repair, or replace any loosened or damaged cable, wire and

connector. If the cable or wire is loosened or twisted, don’t operate the machine.

z Repair switch

Before everyday operation, check the function of key switch and engine emergency stop

switch. If there is any unusuality, repair at once. In

case of fire, if you can’t stop engine, it will aggravate

firepower, and may cause GBH.

z Clean out inflammable materials

Spilled fuel, stored breeze, and other inflammable

materials may cause fire. Keep the machine clean

every day to prevent fire.

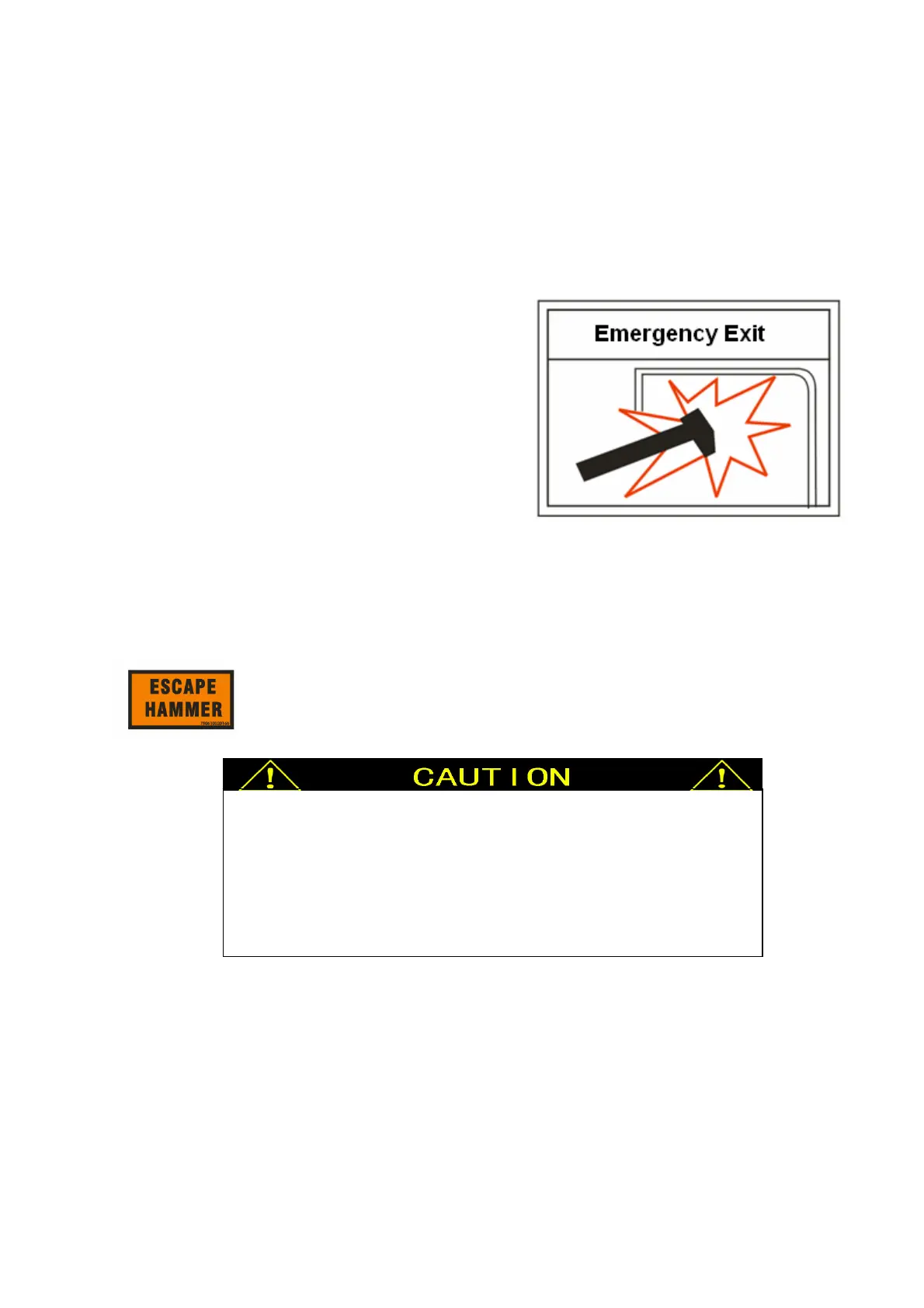

1.35 EMERGENCY EXIT

Emergency exit mark is shown in right figure:

When there is an emergency and the operator can not get out of the cabin, take the small hammer

hung on the wall in cabin to break the window with emergency exit mark to leave the machine.

The cabin safety structure can not be repaired after damage but it can be replaced with other

qualified safety protective structures.

1.36 Noise and vibration

The emission sound pressure level at the operator's and the sound power level of machine are

measured according to ISO 6396:2008 considering the method of ISO 3744:2009 under the

operation condition required in EU Directive 2000/14/EC and 2005/88/EC, the test results as

below:

The A-weighted emission sound pressure level at the operator's position is:

L

pA

= 80 dB, which is less than 80 dB required in EN 474-1:2006+A1:2009.

The sound power level of the machine is:LWA= 93 dB, which complied with the limit of

2000/14/EC and 2005/88/EC

1. Pay attention not to be hurt by the splashing objects while

breaking the window with a certain distance to the breaking hole

for safety.

2. The breaking hole should be big enough for operator to get out

(according to operator’s own condition) and the hole should have

no sharp spines for safety.

Loading...

Loading...