OPERATION & MAINTENANCE MANUAL SWE215F

accumulated lubricating grease, oil or debris.

Always disconnect negative terminal from battery

before testing on electrical system or welding on the

machine.

Provide complete lighting device for jobsite. When

working under the machine or inside the machine,

always use maintenance work light with protective

hood. Or broken bulb pieces may ignite flammable

fluid e.g. spilled fuel, engine oil, anti-freezing fluid

etc.

Do not make contact with coolant, in case of contact;

there may be some hazards of blindness, for the skin,

cold injury may occur.

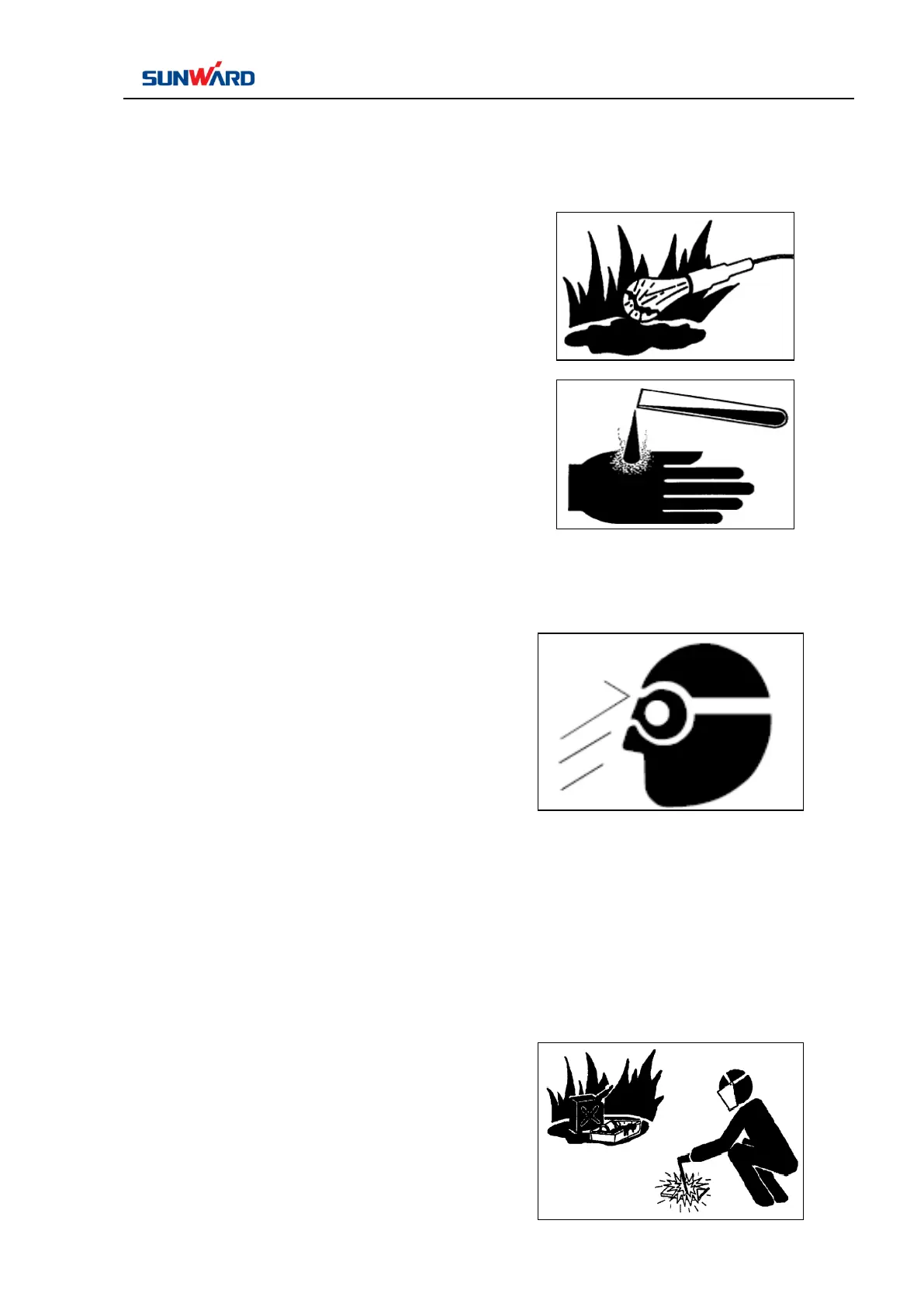

When using pressed air to clean up, injury or damage

can occur due to flying-out particles. When using

pressed air to clean up filter core or radiator, always

wear goggles, dust-preventive mask, gloves and other

protective items.

1.4.4 Tips for Using a Hammer

When using a hammer, pins may fly out or metal

particles may be scattered. This may lead to serious

injury, always do as follow.

When using a hammer to hit hard metal parts, say

pins, bucket teeth, cutting edges or bearings. There

involves some hazards that pieces may be scattered

and lead to injury. Always wear goggles and gloves.

When hitting pins or bucket teeth, there may be some

hazards that broken pieces may fly out causing injury

to surrounding persons. Make sure the surrounding

area is off limits to the other people.

When hitting the pins with tough force, there are

some hazards that pins may fly out causing injury to

surrounding people.

1.4.5 Precautions of Welding and Polishing

Welding operation can generate flame and gas.

Operate must be therefore carried out in

well-ventilating area with complete preparation.

Store flammable substance in safe place prior to

welding operation.

Loading...

Loading...