63

6.3 Calibration

The sensors used with the SF-902S should be periodically calibrated for highest measurement accuracy.

Not all sensor channels require calibration. Some, such as thermocouples, are calibrated at the factory and

normally do not need re-calibration. Pressure transducers and analog voltages, have the calibration set in

the conguration le based on the manufacturer’s specications.

As a rule, the source used to calibrate a sensor should be 10% more accurate than the sensor being

calibrated. For example, if a sensor has an accuracy of +/–1%, the standard used to calibrate it should

have an accuracy of +/–0.1%.

Calibrating the Sensors

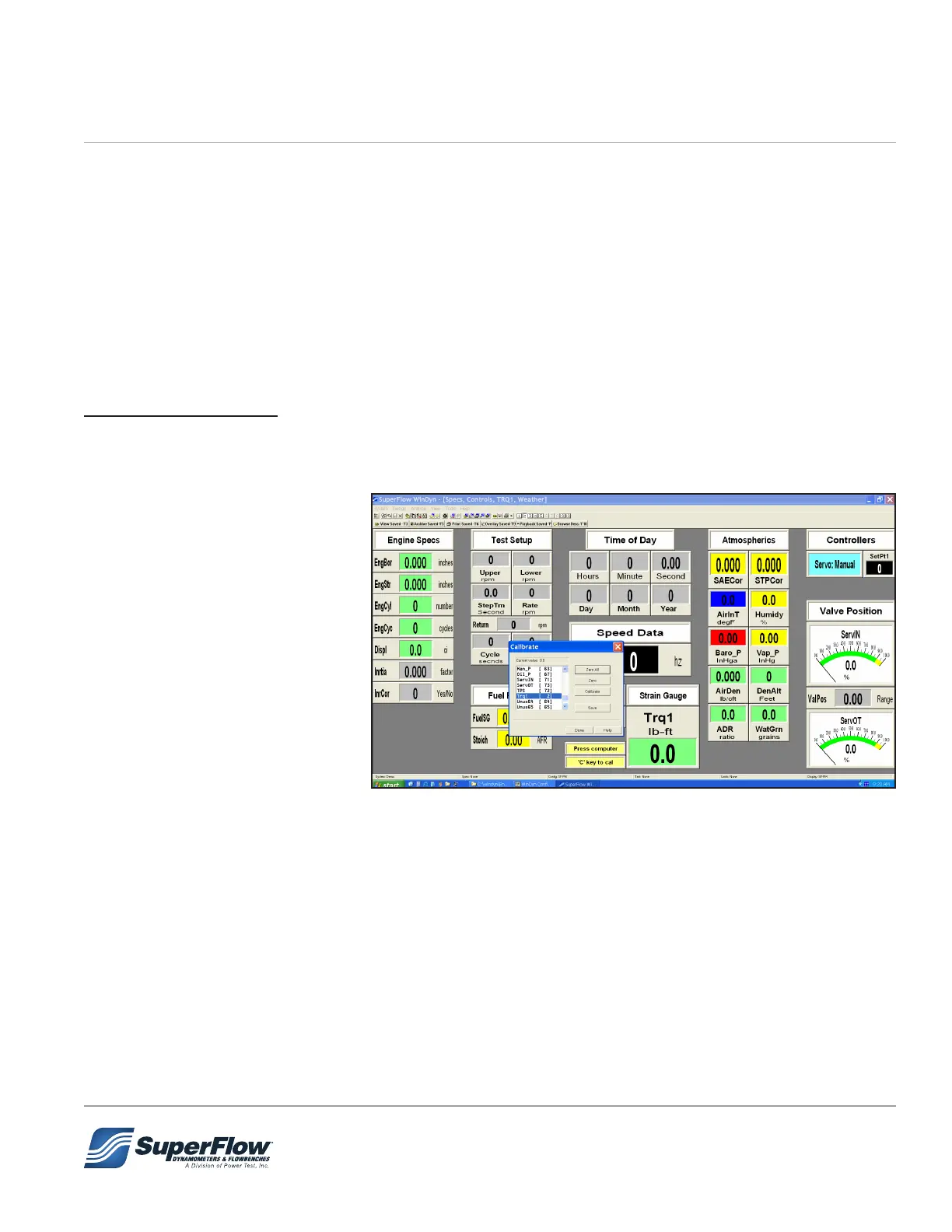

NOTE: The following procedures are performed using the WinDyn Data Acquisition and Control Software,

please refer to the software manual for additional calibration details.

Torque:

15. Power on computer system.

16. Power on dyno system.

17. Launch WinDyn application.

18. Use System | Install | Test

Group menu option (or F2

key) to load your specic test

group (.tgp) le.

19. Select SCREEN 2 to observe

Trq1 channel (2).

20. Press ‘C’ key on computer

keyboard.

21. Calibration dialog box should

appear on computer screen.

22. Scroll down in channel dialog and highlight ‘Trq1’ channel.

23. Mount cal arm and weight pallet to absorber.

24. Click ‘ZERO’ button.

25. Hang cal weights on weight pallet.

26. Observe ‘Current value = ????’ in Calibrate dialog box.

27. Click ‘Calibrate’ button.

28. Enter computed torque value of hanging weights (Weight x eective length of arm) in calibrate dialog

box. Click OK. The SF-PM system uses a 2 foot arm. The SF-902s and SF-BW use a 3 foot arm.

29. Remove weights and calibration arm

6.0 Maintenance

Loading...

Loading...