73

The troubleshooting tips in the following table may also help diagnose a servo valve or absorber problems.

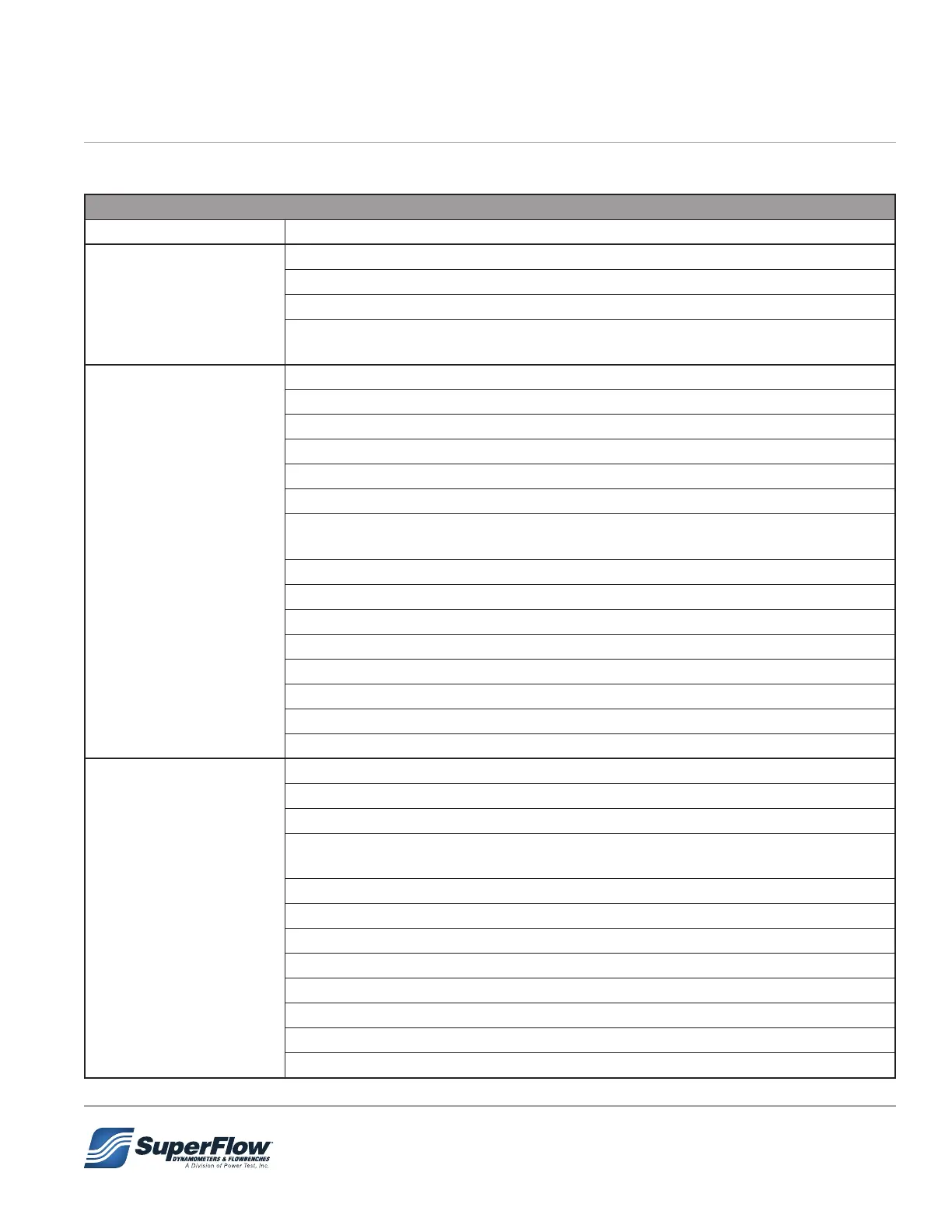

Troubleshooting Chart

Symptom Possible Cause

Absorber does not load • Insucient water supply

• Servo Valve spool loose or incorrectly indexed

• Absorber rotor or stator bad

• Normal condition: No water will ow through the PM absorber in NORMAL

conguration, unless the engine RPM >500

Control unstable

(manual mode)

• Engine not running smoothly

• Severe ignition noise

• Insucient water supply

• Capacity of absorber exceeded

• Servo Valve spool loose or incorrectly indexed

• Too much water owing through the absorber

○ Check ValPos value and ServIn position when controlling to EngSpd.

Typical ValPos range is from 1 to 5.

○ Optimum ServIn position is 60-80% for start RPM setpoint

▪ Too low = ValPos too high, decrease ValPos

▪ Too high = ValPos too low, increase ValPos

• Water pressure too high or low

○ Optimum pressure setting is between 50-80 psig

• Water backing up in outlet port of absorber or horn-of-plenty

○ This creates backpressure on the system and aects control

• Check inlet/outlet water temp delta T; optimum delta T is 60-100 degrees F

Control unstable

(EngSpd mode); RPM

rate inconsistent with

selected rate

• Check in Manual mode for control problems

• PID control parameters incorrect; load correct le (.ccp)

• Too much water owing through the absorber

○ Check ValPos value and ServIn position when controlling to EngSpd.

Typical ValPos range is from 1 - 5.

○ Optimum ServIn position is 60-80% for start RPM setpoint

▪ Too low = ValPos too high, decrease ValPos

▪ Too high = ValPos too low, increase ValPos

• Water pressure too high or low

○ Optimum pressure setting is between 50-80 psig

• Water backing up in outlet port of absorber or horn-of-plenty

○ This creates backpressure on the system and aects control

• Electronics failure in sensor box

7.0 Troubleshooting

Loading...

Loading...