5

BREW & STEAM TANK SAFETY

Safety Precauons:

Espresso machines have numerous potenal hazards, and it is of paramount importance to Synesso™ that

people servicing our machines take all necessary precauons to ensure their personal safety. When work-

ing on the machine’s boilers (unless otherwise instructed in the direcons):

• Turn the machine o and shut o the incoming water supply.

• Depressurize the boilers as shown below.

When working on any electrical wiring (unless checking voltage or amperage readings or otherwise in-

structed in the direcons) ensure that the machine is switched o at the electrical box and the machine is

unplugged.

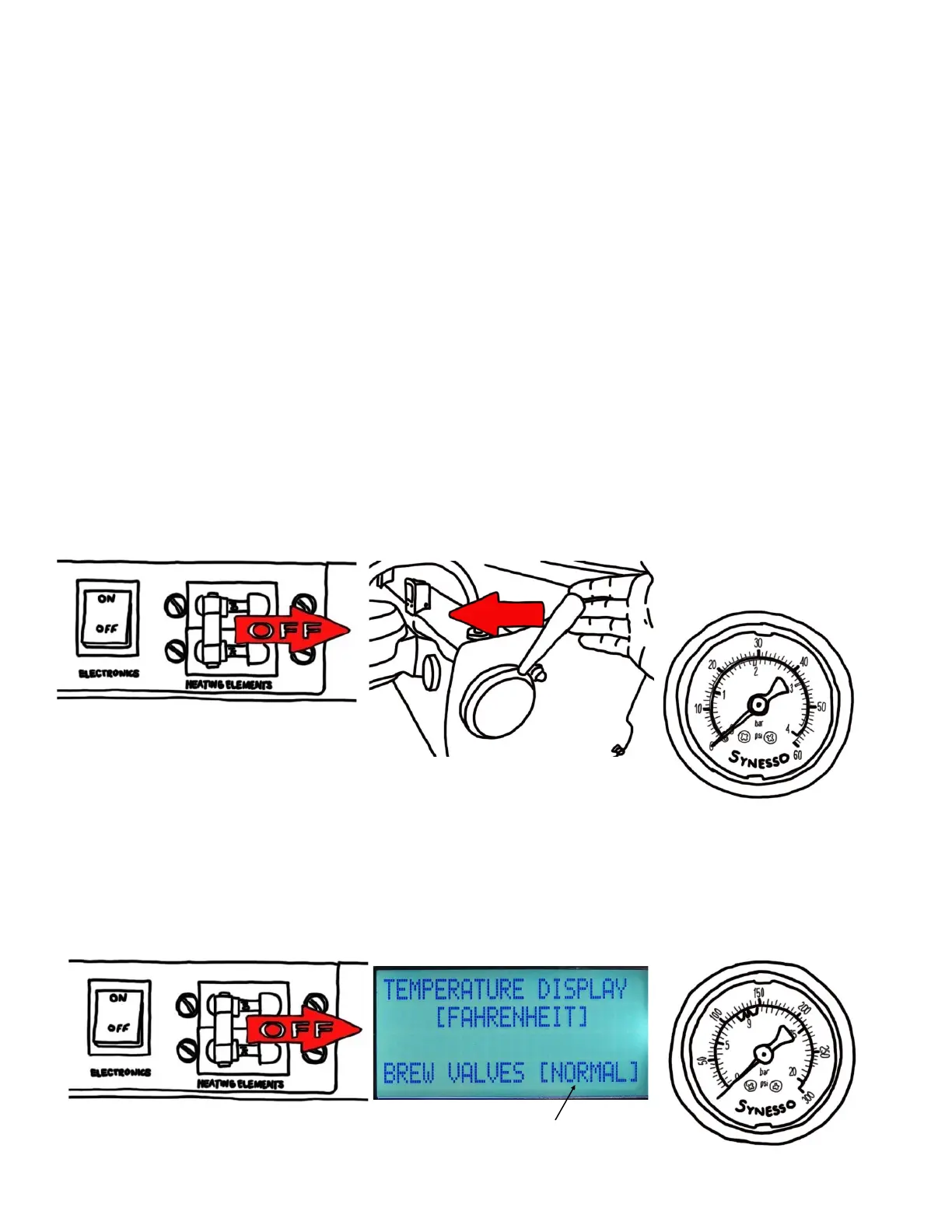

Depressurizing the Steam Tank:

1. Turn o the element circuit

breaker located under the machine.

2. Open the steam valve by moving

the steam actuator lever forward.

3. The steam tank is depres-

surized when the steam gauge

reads zero. Note: the steam

gauge is rated @ 0-60 psi.

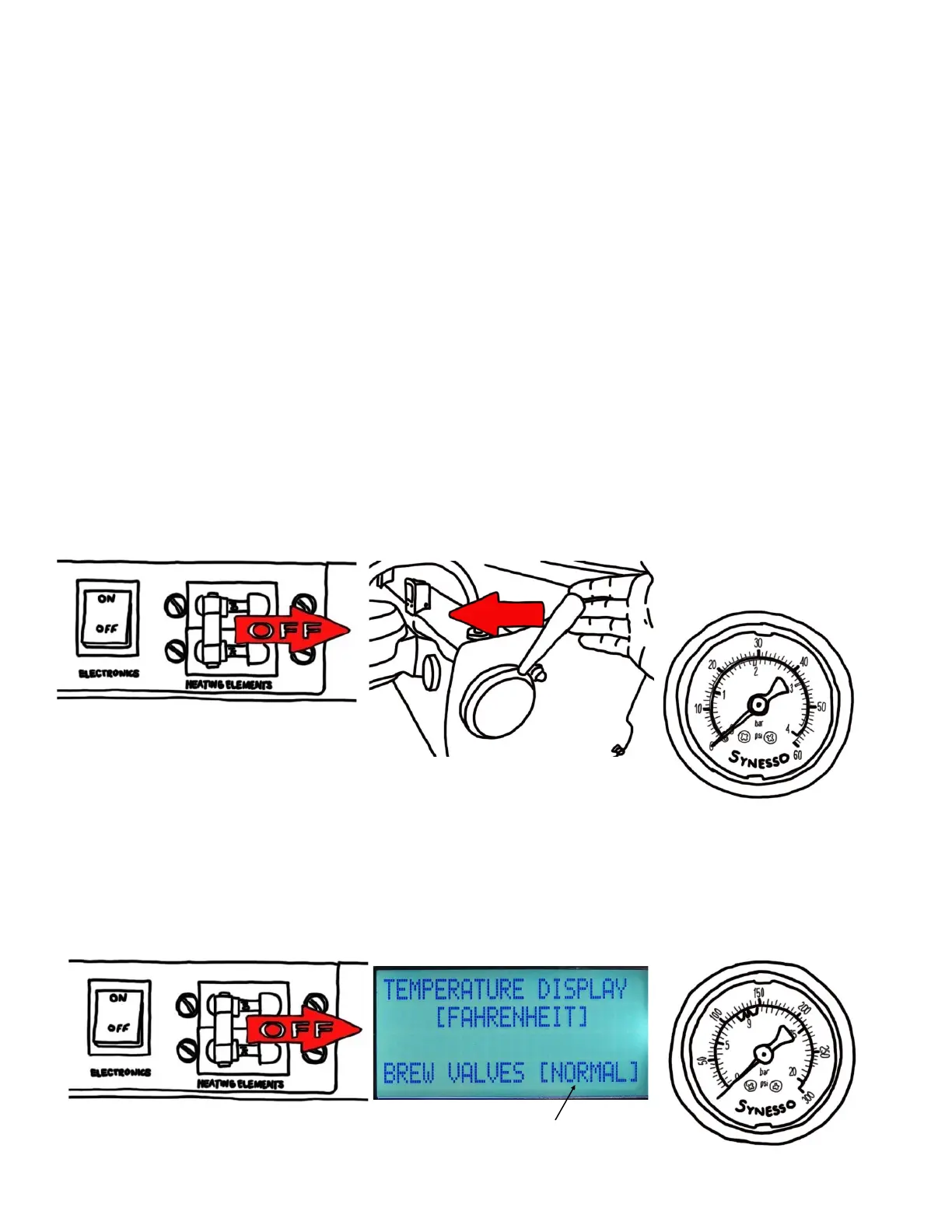

Depressurizing the Brew Tanks:

1. Turn o the element circuit

breaker located under the machine.

2. Also turn o the water supply to

the machine.

4. The brew tanks are depressur-

ized once the pressure gauge

reads zero. Note – the brew

gauges are rated at 0-300 psi.

3. In the second level menu,

change the brew valves from

“Normal” to “ON” this will

bleed the pressure.

Normal to On

Loading...

Loading...