SYNRAD® 32-1 Operator’s Manual Version 2.2

34

Technical Reference

Delivery optics

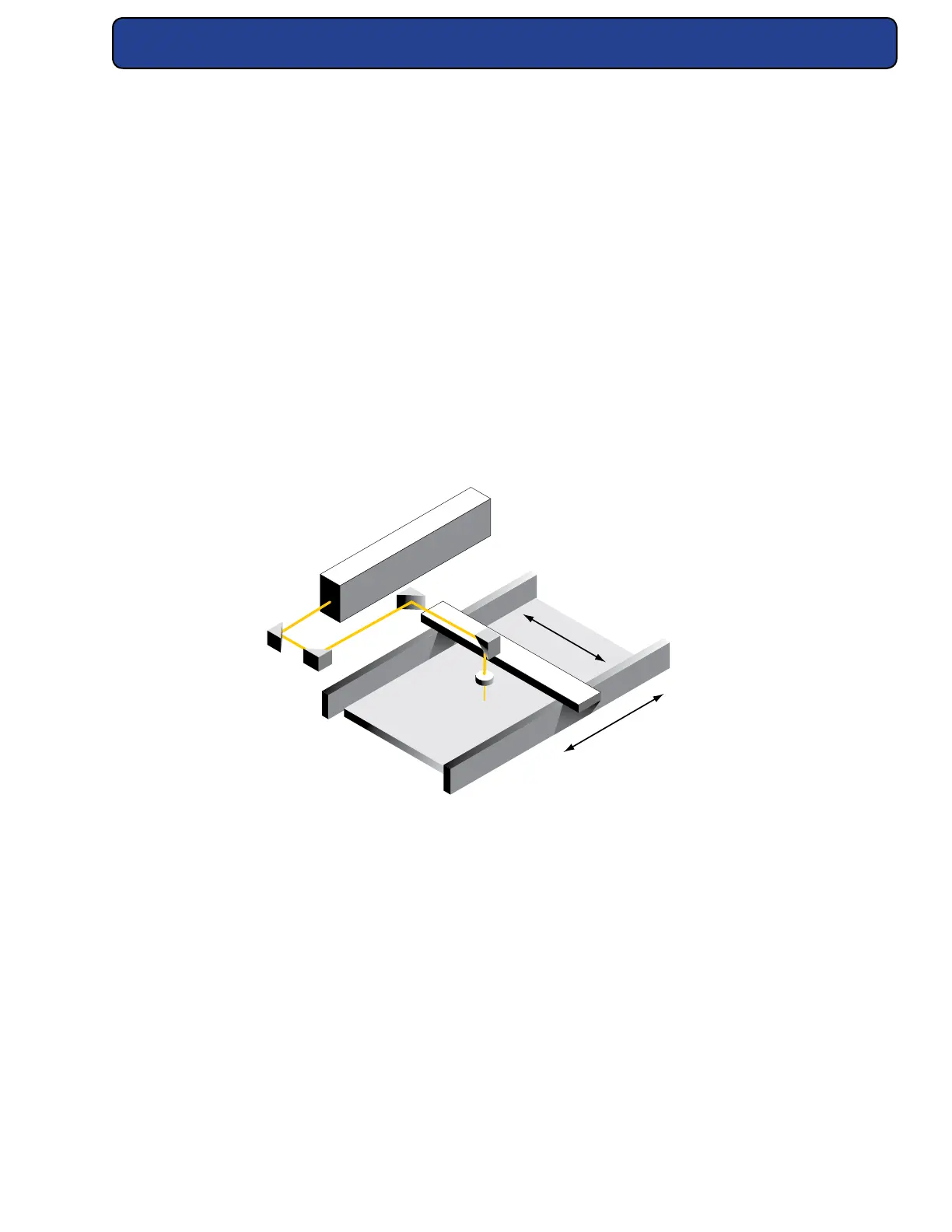

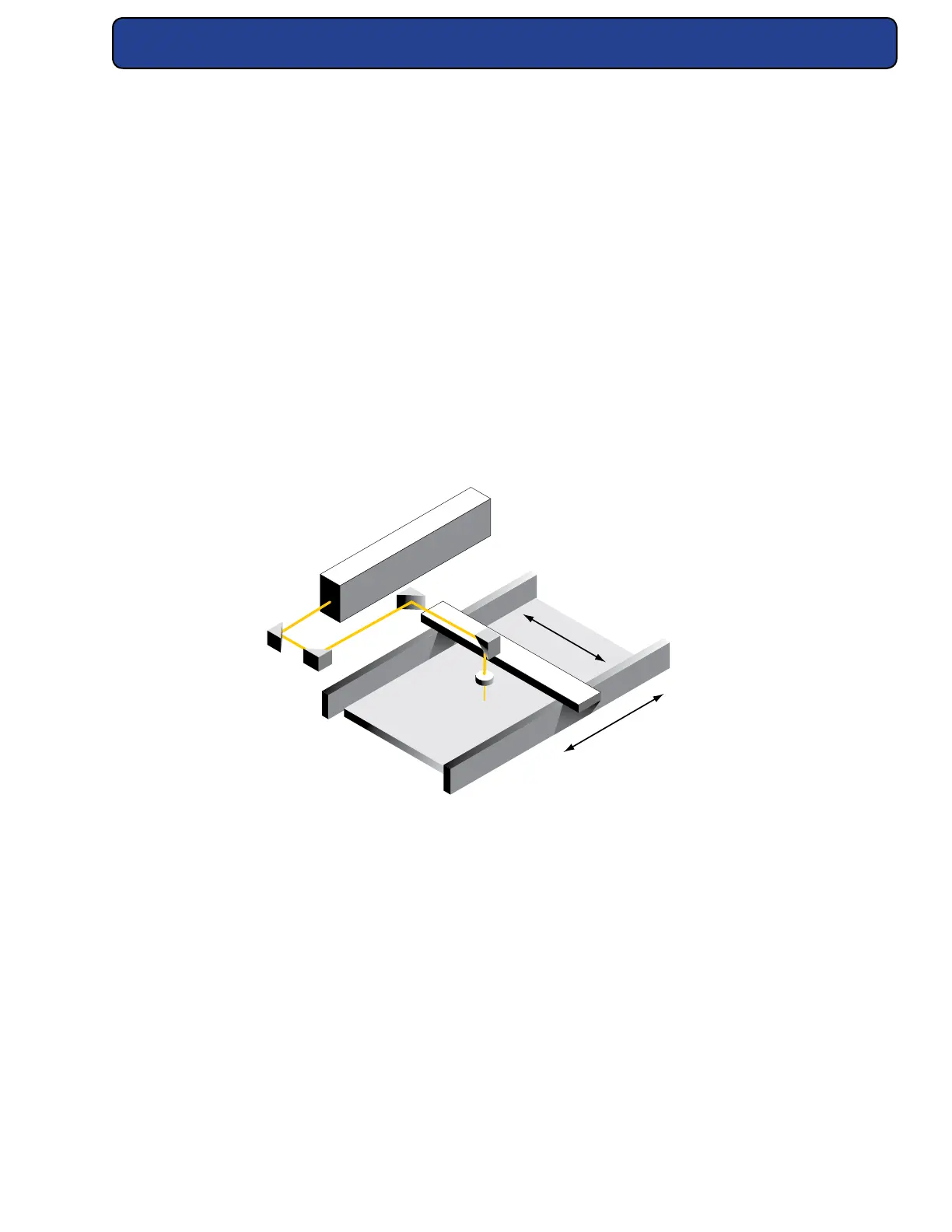

Divergence, or expansion, of the laser beam is important for materials processing since a larg-

er beam entering the focusing optic produces a smaller focused spot. Because the laser beam

diverges slowly, increasing 8 mm in diameter over every meter, 32-1 lasers should be mount-

ed a distance of 1.0–1.5 m (40–60 in) away from the work area. Right angle turning mirrors

are often used in conjunction with the laser mounting position to obtain this distance. Figure

below shows how right angle turning mirrors in a “ying optics” setup create this longer beam

path.

Expander/collimators are optical devices that reduce beam divergence while at the same time

increasing beam diameter by a selectable magnication factor. Adding an expander/collima-

tor to the “ying optics” setup shown below would substantially reduce beam divergence and

any variance in beam diameter caused by the changing optical path length. In xed-length

delivery systems where the laser is positioned only one meter away from the focusing optic

and a small spot size is required, an expander/collimator is again the best solution to provide

the required beam expansion before reaching the focusing optic.

Figure 4-2 “Flying optics” beam path.

Focusing optics

When selecting a focusing optic, the primary consideration should be material thickness and

any vertical tolerances that occur during nal part positioning rather than making a selection

based only on minimum spot size. The chosen focal length should create the smallest possible

focused spot while providing the depth of eld required for the material to be processed. Op-

tics are fragile and must be handled carefully, preferably by the mounting ring only. Be careful

to select optics that are thick enough to withstand the maximum assist gas pressure available

for the process. This is especially important in metal cutting applications using high-pressure

assist gases.

Loading...

Loading...