SYNRAD® 32-1 Operator’s Manual Version 2.2

35

Technical Reference

Cleanliness is another important issue aecting performance and becomes increasingly im-

portant as laser power increases. Dirty or scratched lenses will under perform, exhibit a vastly

shortened lifetime, and may fail catastrophically.

When the application requires air (instead of nitrogen) as an assist gas, use only breathing

quality air available in cylinders from a welding supply company. Compressed shop air con-

tains minute particles of oil and other contaminants that will damage optical surfaces. If com-

pressed shop air is the only choice available, it must be ltered and dried to ISO 8573-1:2010

Class 1, 2, 1 specications shown in the table below.

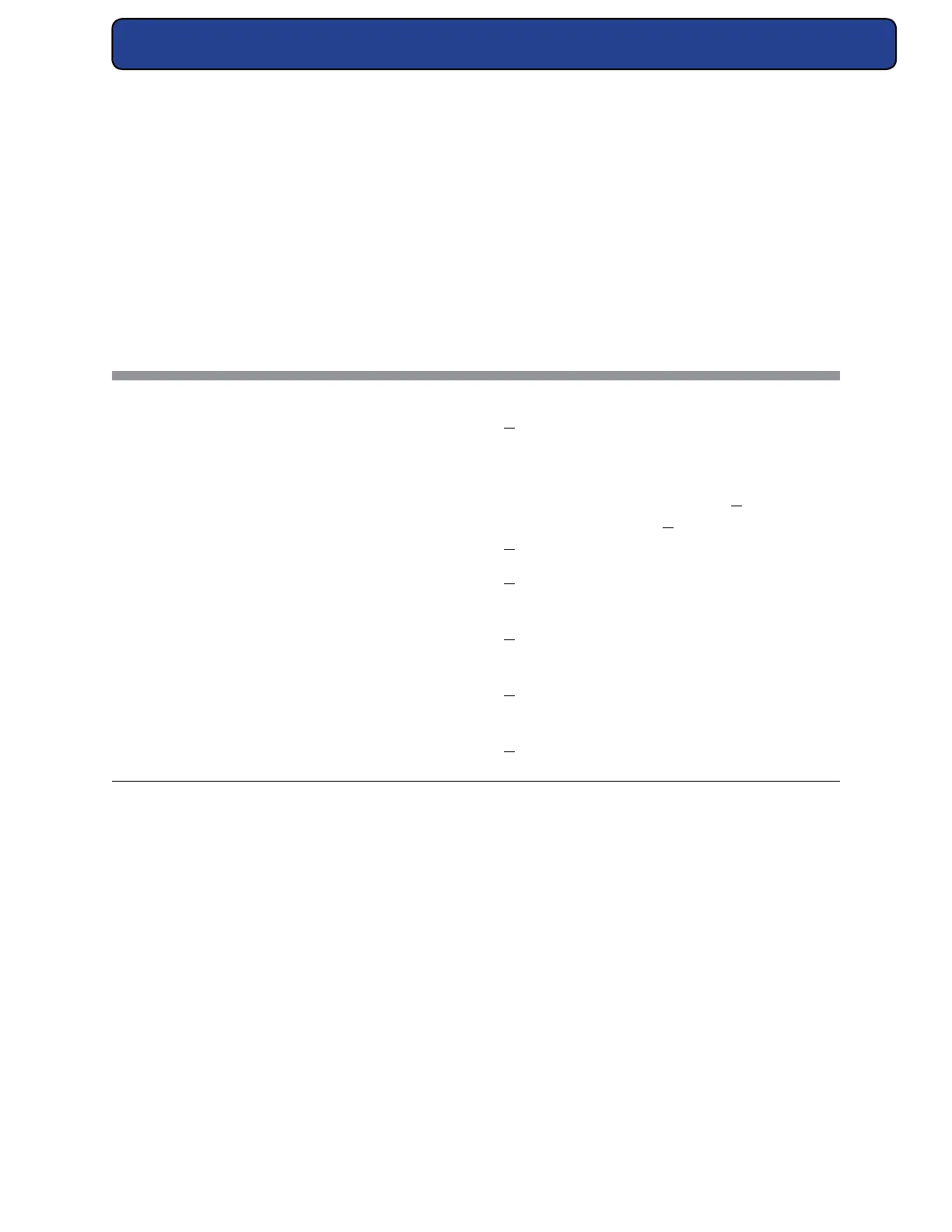

Table 4-2 Assist gas purity specications.

Assist Gas Typical Purpose Specication

Air Cutting/Drilling Breathing Grade > 99.9996% purity; ltered to ISO Class 1

particulate level

Air Cutting/Drilling Compressed Instrument-grade air ltered and dried to

ISO 8573-1:2010 Class 1, 2, 1 (< 10 1.0–

5.0 µm particles/m

3

; < –40 °F dew point;

< 0.01 mg/m

3

oil vapor)

Argon Welding High Purity Grade > 99.998% purity; ltered to ISO Class 1

particulate level

Helium Welding High Purity Grade > 99.997% purity; ltered to ISO Class 1

particulate level

Nitrogen Cutting/Drilling High Purity Grade > 99.9500% purity; ltered to ISO Class 1

particulate level

Oxygen Cutting/Drilling Ultra Pure Grade > 99.9998% purity; ltered to ISO Class 1

particulate level

Loading...

Loading...