English

For heatpump models, if the outdoor temperature is likely to fall below +1°C, provide a system to

prevent the condensates from freezing (e.g. heating cord).

Caution

THE USE OF A GLYCOL-BASED SOLUTION IS THE ONLY EFFECTIVE FROST-PROTECTION MEANS

Caution

Never ll the hydraulic circuit with pure glycol. Maximum glycol concentration is 45%. The water

and glycol mixture must be precisely prepared before lling the hydraulic circuit. If the mixture is

too much concentrated, the hydraulic could be damaged and the unit SysAqua should not perform

normally. In this case, unit guarantee will be cancelled.

Caution

The glycol percentage in the installation's hydraulic circuit must be entered in the regulation upon

start-up. This parameter setting changes the safety and alarm triggering threshold limits. An incorrect

value may cause malfunctions and a destruction of the unit's heat exchanger.

Caution

Avertissement

It is strongly recommended to post, on the electric box of the unit, glycol type and concentration in

the hydraulic circuit.

15SysAqua

10.6. FROST PROTECTION

If the SysAqua is exposed to ambient temperatures between 1°C and -18°C, protect the water circuit

against frost.

Draining the water circuit is not recommended for frost protection, for the following reasons:

² The water circuit will rust, which will shorten its lifetime.

² Water will remain at the bottom of the plate exchangers and freezing may cause damage.

The glycol-based water solution must be sufciently concentrated to ensure appropriate protection and

prevent ice from forming at the minimum outdoor temperatures planned for the installation. Take precautions

when using non inert MEG antifreeze solutions (Mono Ethylene Glycol or MPG Mono Propylene Glycol). With

this type of antifreeze solution, corrosion may occur in the presence of oxygen.

Contact glycol resellers to ensure that its characteristics are compatible with environmental directive

applicable on site (this is not under manufacturer responsibility).

The glycol-based solution slightly modies the installation's performance, particularly in terms of load loss:

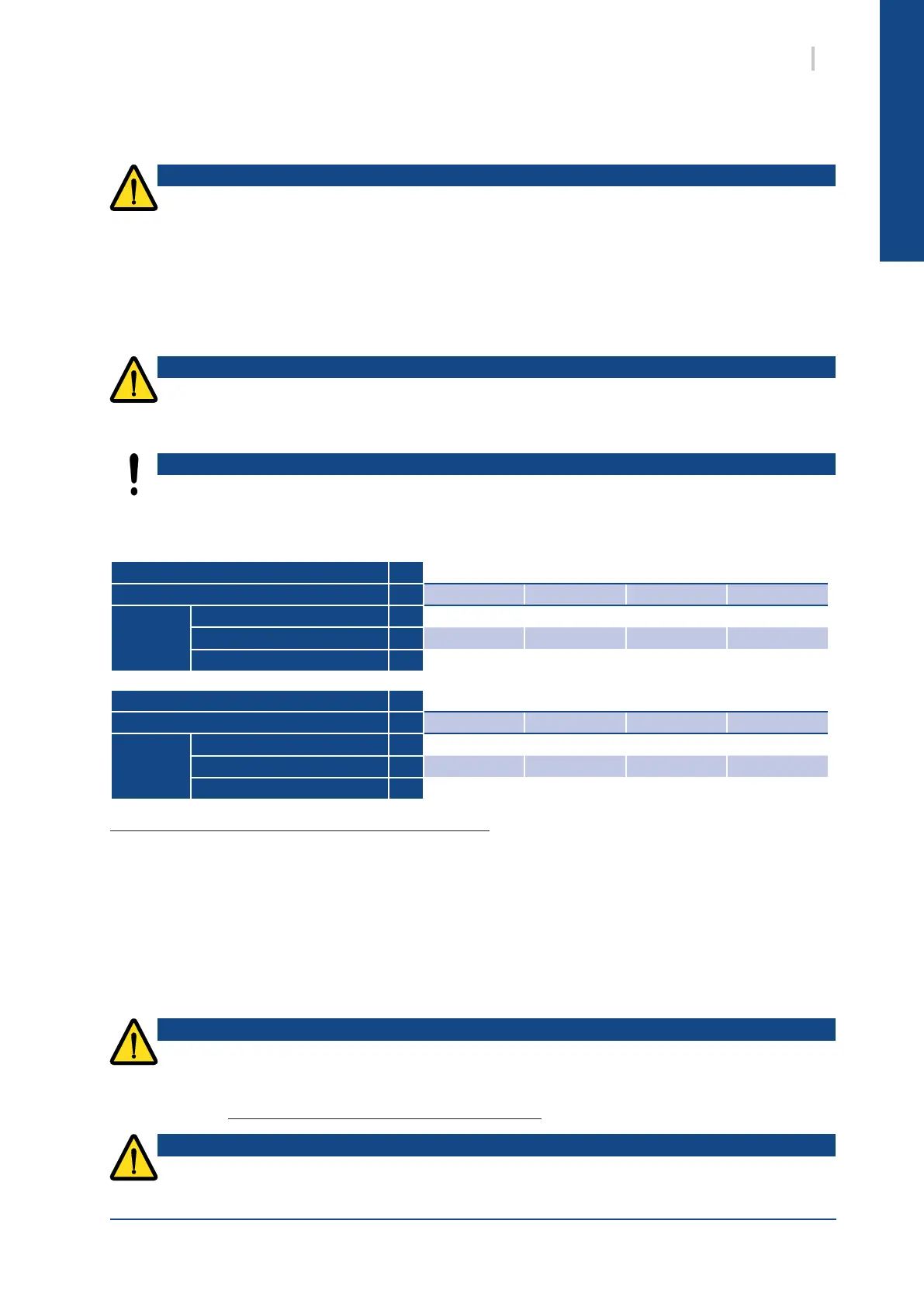

Minimum outdoor temp. °C

5 > T > 0 0 > T > -5 -5 > T > -10 -10 > T > -30

Mono Ethylene Glycol concentration %

10 20 30 45

Correction

factor

load loss

1.070 1.160 1.235 1.368

water ow

1.015 1.050 1.085 1.169

thermodynamic power

0.995 0.985 0.970 0.949

Example for a solution with 20% Mono Ethylene Glycol:

² Increase the pressure drop : with glycol = 1.160 x without glycol

² Increase the owrate : with glycol = 1.050 x without glycol

² Decrease the capacity : with glycol = 0.985 x without glycol

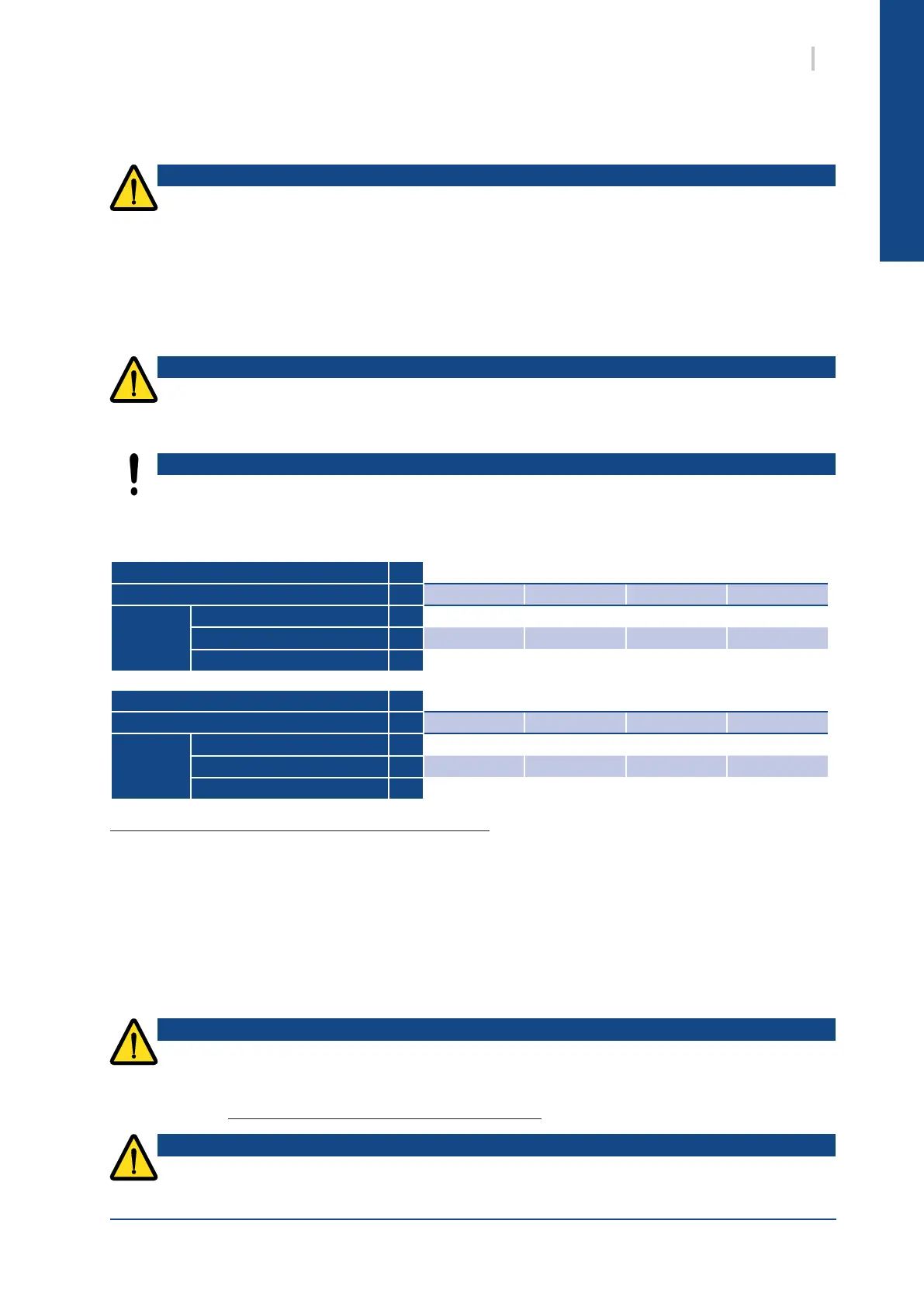

Minimum outdoor temp. °C

5 > T > 0 0 > T > -5 -5 > T > -10 -10 > T > -27

Mono Propylene Glycol concentration %

10 20 30 45

Correction

factor

load loss

1.112 1.175 1.290 1.520

water ow

1.005 1.030 1.067 1.162

thermodynamic power

0.991 0.977 0.945 0.894

Loading...

Loading...