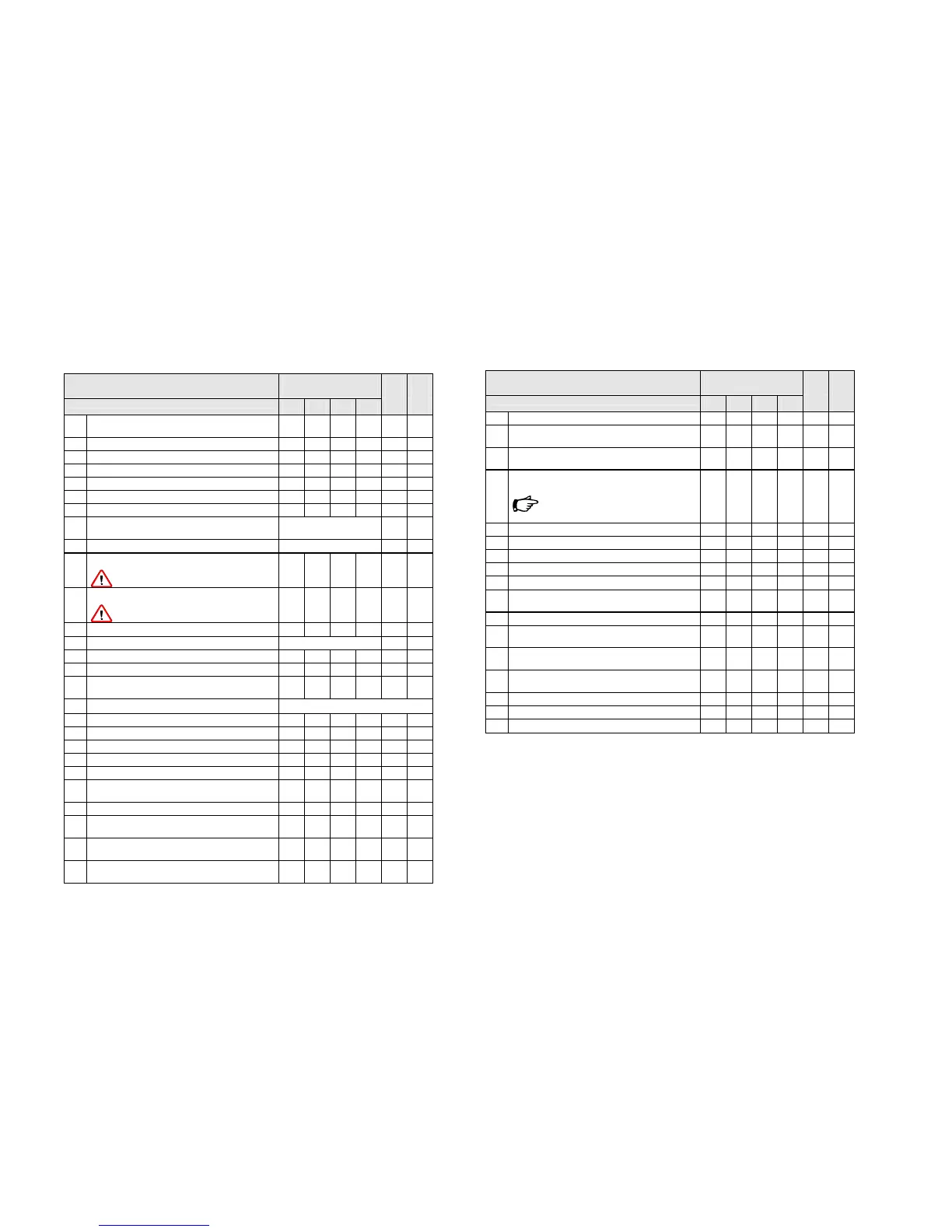

Inspection plan

Work to be carried out by trained specialist dealer personnel

O = Checking, maintenance

X = Replace

Operating hours

min

2x

min

1x

Perform work with machine at operating temperature

after

100

every

500

every

1000

every

2000

year-

ly

year-

ly

1 Check machine for presence of machine-specific

operating instructions

O O

2 Change the engine oil X X

3 Change the engine oil filter X X

4 Drain water from the fuel tank O O O

5 Replace the fuel filter X X

6 Clean fuel pump, sieve filter O

7 Check air intake O O

8 Replace main air filter cartridge according to the service

indicator

X

9 Replace the air filter safety cartridge as required

1)

10 Clean cooling fins on hydraulic oil cooler O O O

The cleaning intervals should be

shortened if there is high exposure to dust.

11 Clean cooling fins on engine oil cooler O O O

The cleaning intervals should be

shortened if there is high exposure to dust.

12

Check antifreeze level in coolant O

13

Change coolant as required

1)

14 Check V-belt tension O O

15 Check engine mount and pump attachment O O

16 Check engine speed setting, upper and lower idle

speeds

O O

17 Check valve lash of engine and adjust if necessary

1x every 500 OH and as required

18 Check injection valves O

19 Check or replace the fuel leakage oil lines O X

1)

20 Replace toothed belt

3)

21 Check crankcase breather in valve cover O

22 Check acid level and battery connections O O

23 Check condition of tires, tire pressure and fastening

of wheel nuts

O O

24 Check fastening of axles and propeller shaft O O

25 Check bearing bushings and bolts of work

equipment and replace if necessary

O O

26 Check bushings and bolts of the articulation and the

articulated steering and replace if necessary

O O

27 Check that door catches function perfectly, and

replace if necessary

O O

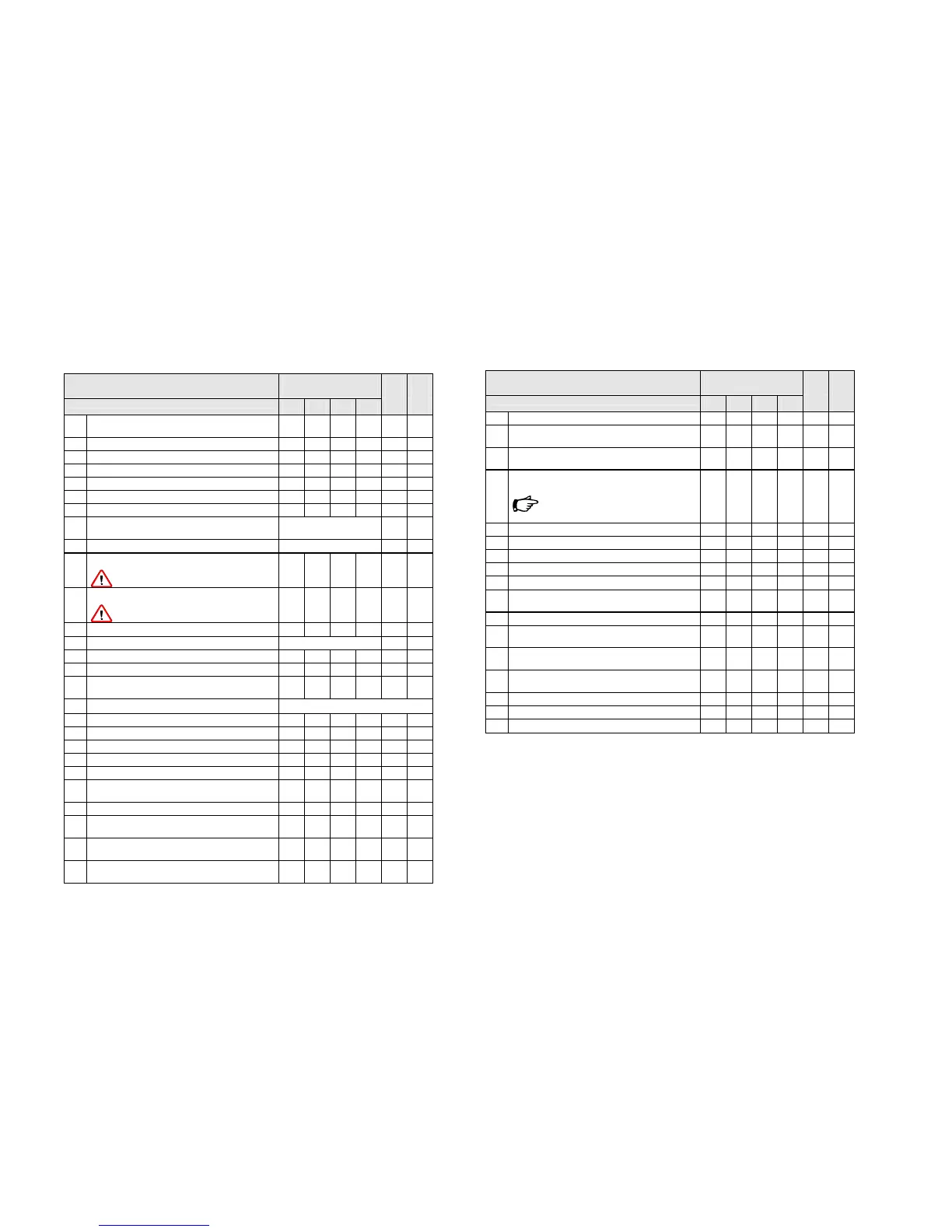

O = Checking, maintenance

X = Replace

Operating hours

min

2x

min

1x

Perform work with machine at operating temperature

after

100

every

500

every

1000

every

2000

year-

ly

year-

ly

28 Clean or replace the dust filter for cab ventilation O X X

29 Check electrical indicating and warning elements as

well as lighting equipment.

O O

30 Check smooth running of operator controls and

adjust if necessary

O O

31 Check tightness of all pipes, hoses, control valves,

hydraulic pumps, cylinders, etc.

O O

When tightening hose and pipe

connections, screw-in couplings must be

locked to prevent rotation.

32 Check or change hydraulic oil O O X

2)

X

33 Replace insert of hydraulic oil return suction filter X X X

34 Replace the breathing filter X X

35 Check function of brakes, replace brake oil O O X X

36 Bleed brake O O

37 Differential of rear axle with transmission / option:

manual transmission, oil check and/or oil change

X O X X

38 Differential - front axle oil: check or oil change resp. X O X X

39 Wheel hubs of front and rear axles: oil check or oil

change

X O X X

40 Lubricate the machine according to overview of

lubricating points

O O

41 Check function, condition and completeness of

safety equipment

O O

42 Hydraulic function check with function pressure test O O

43 Test run and test work O O

44 Sign inspection card and return to manufacturer O O

4)

1) at least every 2 years

2) Extension of oil change intervals according to oil sample analysis and laboratory report

For further information see Operating Instructions

3) every 5 years or 3,000 running hours

4) under warranty

Loading...

Loading...