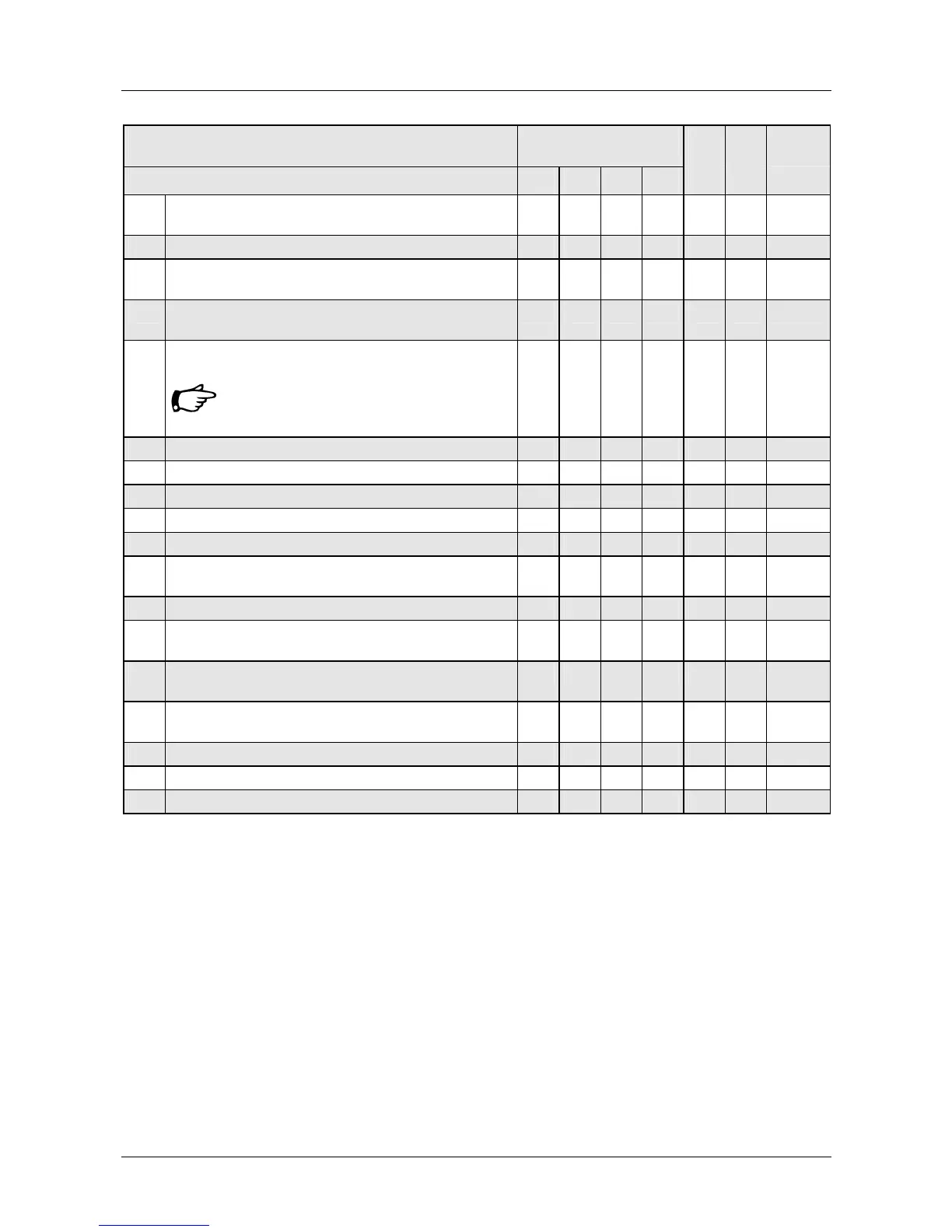

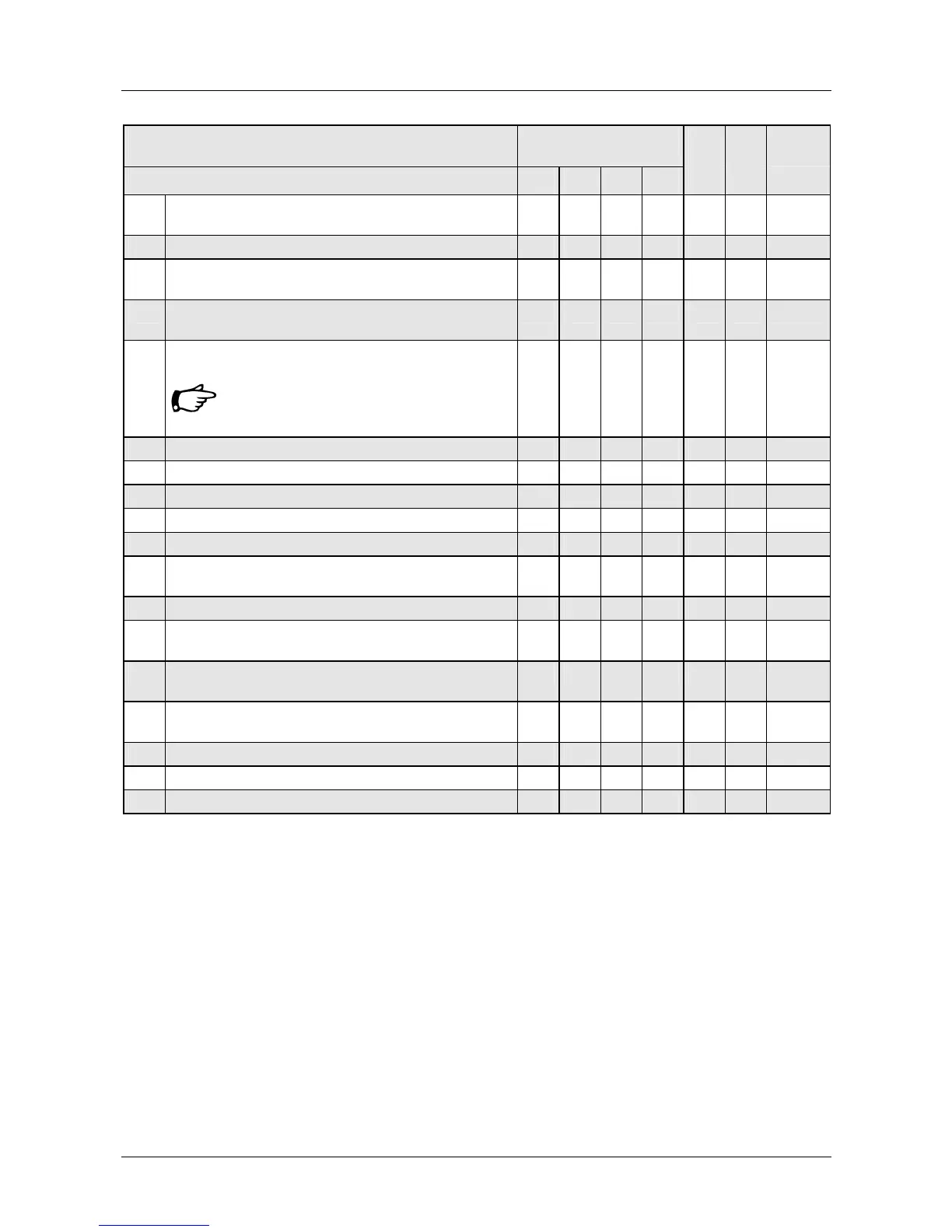

Maintenance and Care 7

TW9 75

O = Checking, maintenance

X = Replace

Operating hours

min

2x

min

1x

Perform work with machine at operating temperature

after

100

every

500

every

1000

every

2000

year-

ly

year-

ly

Chapter

27

Check that door catches function perfectly, and

replace if necessary

O O --

28 Clean or replace the dust filter for cab ventilation

O X X

7.9.18

29

Check electrical indicating and warning elements as

well as lighting equipment.

O

O --

30

Check smooth running of operator controls and

adjust if necessary

O O --

31

Check tightness of all pipes, hoses, control valves,

hydraulic pumps, cylinders, etc.

O O --

When tightening hose and pipe connections,

screw-in couplings must be locked to

prevent rotation.

32 Check or change hydraulic oil

O O X

2)

X

7.9.9

33 Replace insert of hydraulic oil return suction filter

X X X

7.9.11

34 Replace the breathing filter

X X

7.9.12

35 Check function of brakes, replace brake oil

O O X X

7.9.8

36 Bleed brake

O O

7.9.8

37

Differential of rear axle with transmission / option:

manual transmission, oil check and/or oil change

X O X X

7.9.13

38 Differential - front axle oil: check or oil change resp.

X O X X

7.9.13

39

Wheel hubs of front and rear axles: oil check or oil

change

X O X X

7.9.13

40

Lubricate the machine according to overview of

lubricating points

O O

7.8.3

41

Check function, condition and completeness of

safety equipment

O O

--

42 Hydraulic function check with function pressure test

O O

--

43 Test run and test work

O O

--

44 Sign inspection card and return to manufacturer

O

O

4)

7.4

1) at least every 2 years

2) Extension of oil change intervals according to oil sample analysis and laboratory report.

For further information see section 7.3.

3) every 5 years or 3,000 running hours

4) Within warranty.

Loading...

Loading...