Section 6

6-1

Models 340, 341, 342

Operating Procedure

6

Operating Procedure

Model 341 has been selected to illustrate the pictured

step-by-step operating procedures for the models

contained in this manual. Each machine has a 20 qt.

(18.9 L) mix hopper and the freezing cylinder holds 7 qt.

(6.6 L) of slush product. Model 342 has two mix hoppers

and two freezing cylinders. Therefore, duplicate the

procedures (where applicable) for the second side of

Model 342.

Note: Model 342 comes equipped with two door

options: a standard door without a prime plug or a

self-closing door with a prime plug. Follow the

appropriate assembly procedures for your style door.

We begin our instructions at the point where we enter the

store in the morning and find the parts disassembled and

laid out to air dry from the previous night’s brush cleaning.

These opening procedures will illustrate how to

assemble these parts into the freezer, sanitize them,

and

prime the freezer with slush base in preparation to

serve

the first portion.

If you are disassembling the machine for the first time or

need information to get to this starting point in our

instructions, turn to

Disassembly on page 6-13, and start

there.

Assembly

WARNING! Make sure the power switch is in

the OFF position. Failure to follow this instruction may

result in severe personal injury from hazardous moving

parts.

Note: When lubricating parts, use an approved food

grade lubricant (example: Taylor Lube).

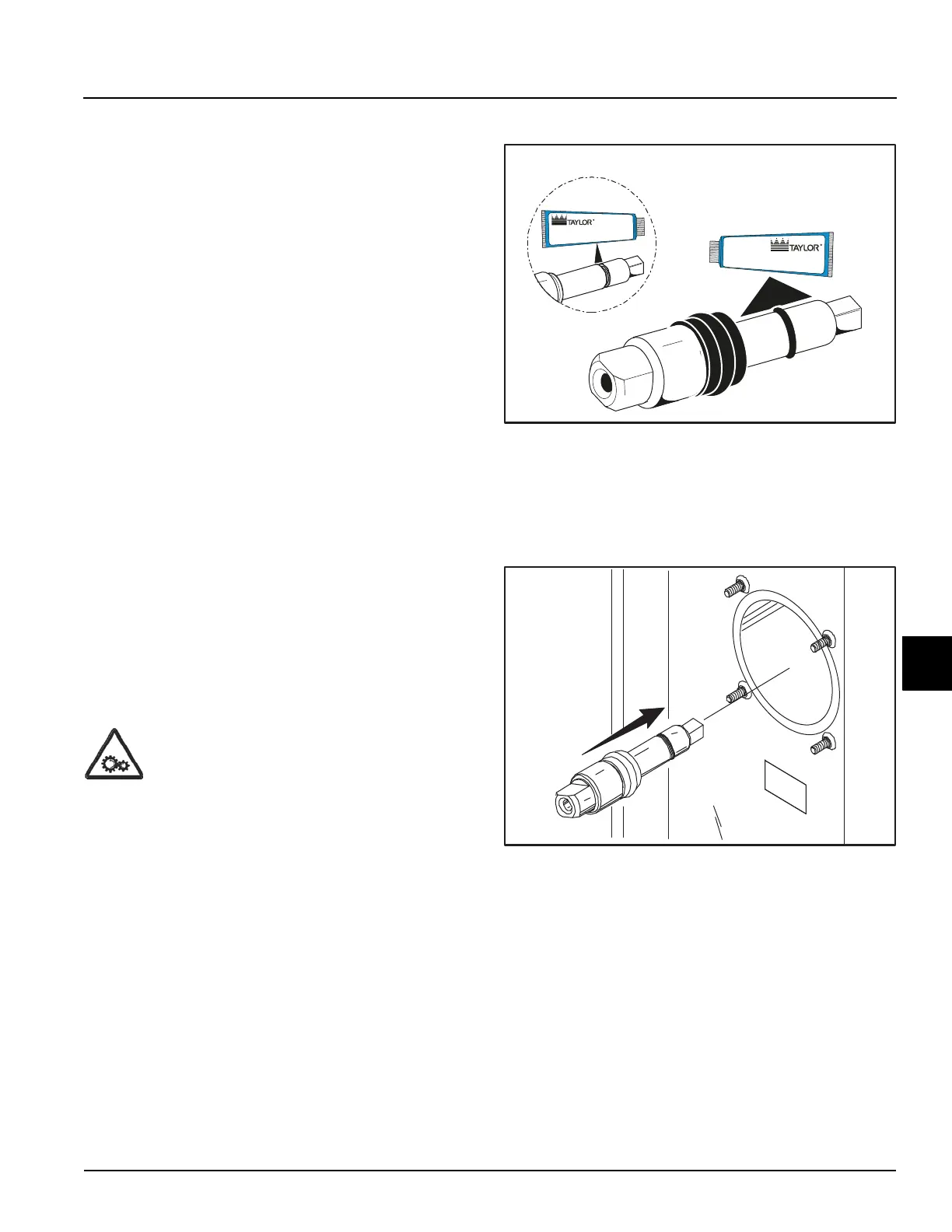

1. Slide the O-ring into the first groove on the drive

shaft. Lubricate the groove, O-ring, and shaft portion

that comes in contact with the bearing on the beater

drive shaft.

Do not lubricate the square end of the drive shaft.

Slide the seal over the shaft and groove until it snaps

into place. Fill the inside portion of the seal with 1/4

more lubricant and evenly lubricate the flat side of the

seal that fits onto the rear shell bearing.

Figure 6-1

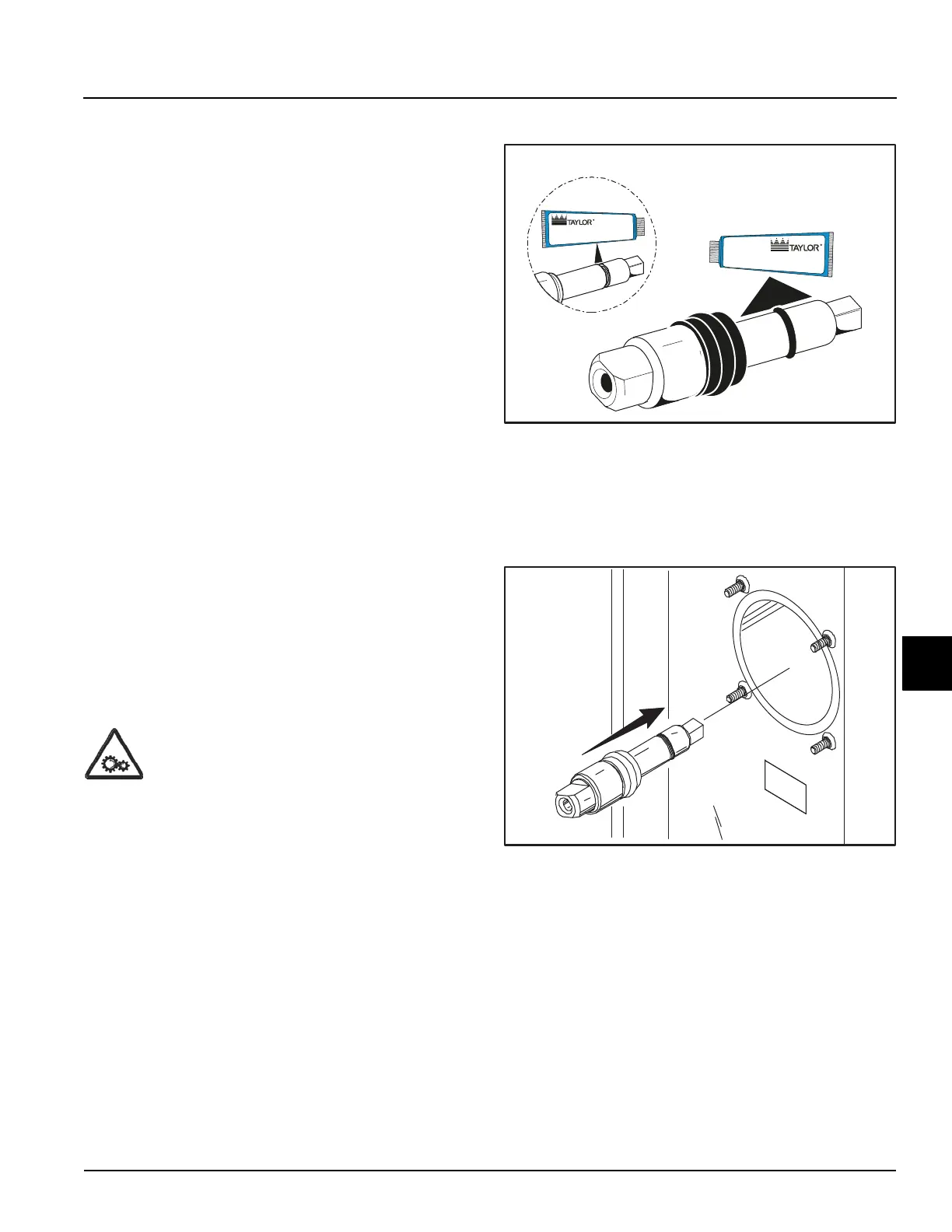

2. Insert the drive shaft into the freezing cylinder,

(square end first) and into the rear shell bearing, until

the seal fits securely over the rear shell bearing. Be

certain the drive shaft fits into the drive coupling

without binding.

Figure 6-2

3. Before installing the beater assembly, inspect the

scraper blades.

Check the scraper blades for any signs of wear or

damage. If a scraper blade is nicked or worn, replace

both blades.

4. If the blades are in good condition, place the rear

scraper blade over the rear holding pin (knife edge to

the outside). Holding the blade on the beater, turn it

over and install the front blade the same way.

11369

Apply the appropriate

Taylor approved food safe lubricant.

Apply the appropriate

Taylor approved food safe lubricant.

Loading...

Loading...