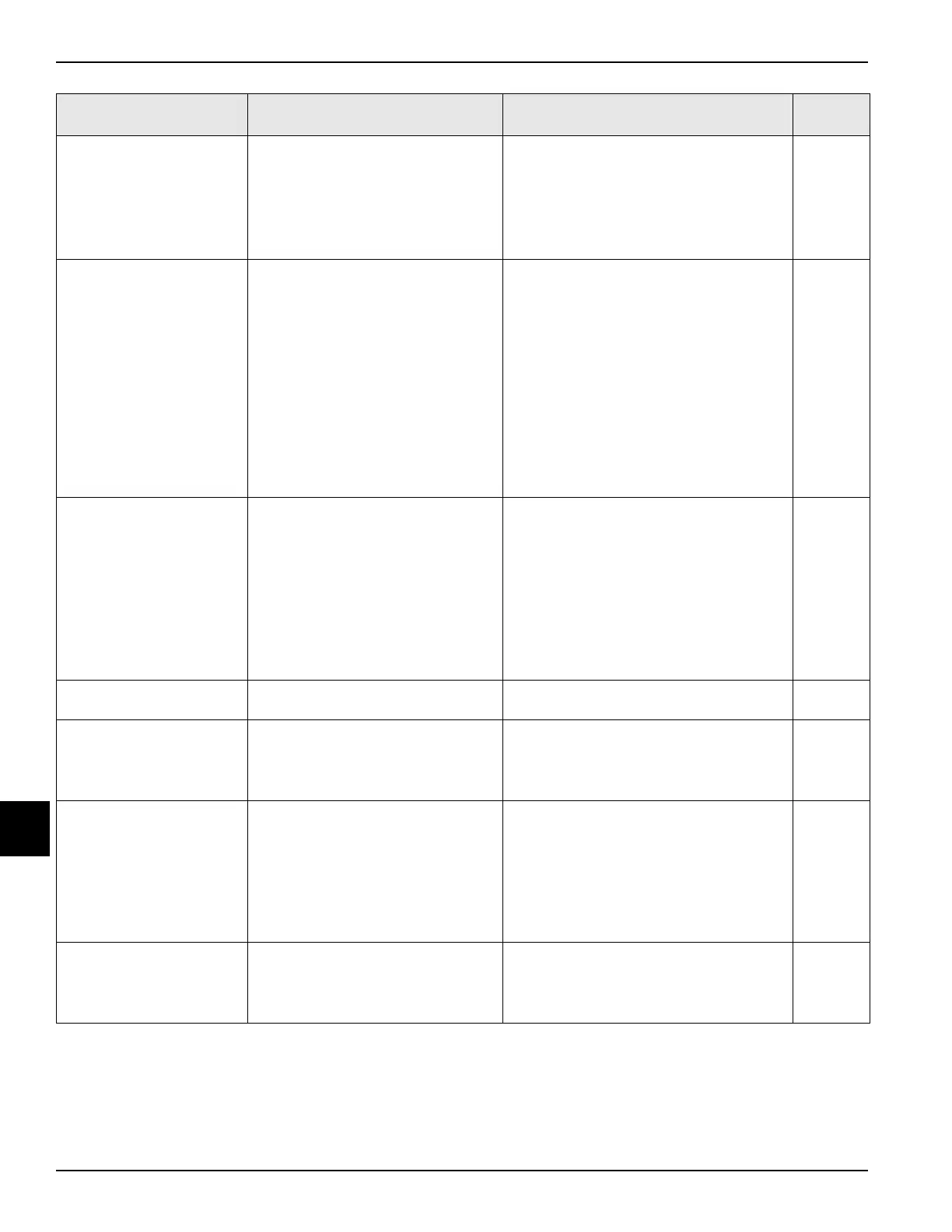

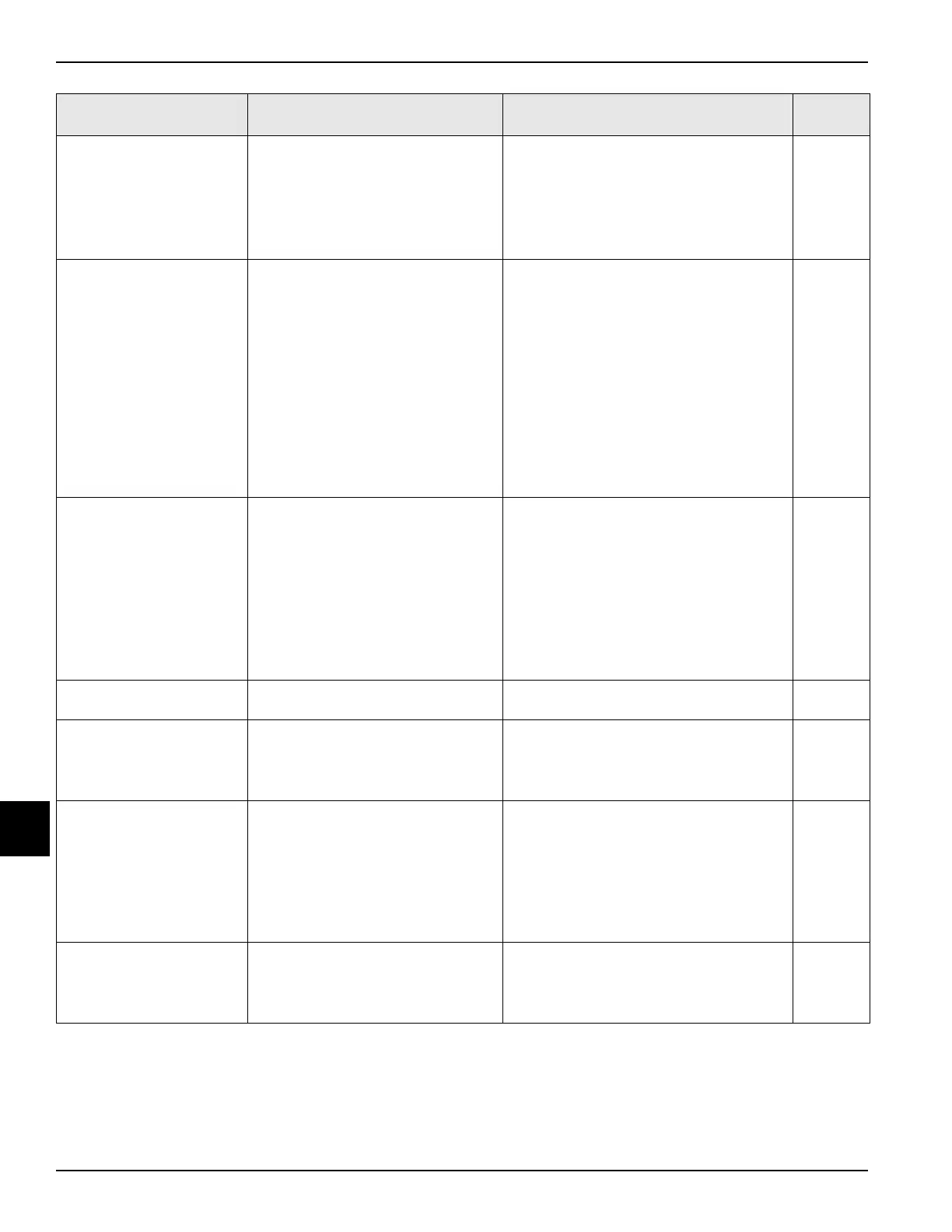

8-2

TROUBLESHOOTING GUIDE

Model 8756

Troubleshooting Guide

8

3. Product is too stiff. a. Insufficient mix in the freezing

cylinder.

a. Refer to problem #2.

- - -

b. Improper priming procedures. b. Drain the freezing cylinder and reprime

the machine.

6-12

c. Out-of-date mix. c. Use fresh mix. 6-12

d. Viscosity control is set too cold. d. Contact a Taylor service technician. - - -

4. Product is too soft. a. Worn scraper blades. a. Replace scraper blades regularly. 9-1

b. Dirty condensers or air filters on

air-cooled machines.

b. Clean monthly.

7-1

c. Inadequate water supply on

water-cooled machines.

c. Check the water supply. Check water

lines for leaks or kinks.

7-1

d. Inadequate airspace around

air-cooled machines.

d. Allow adequate room for airflow across

the condensers. Minimum of

3 in. (76 mm) clearance on all sides. Do

not obstruct the air discharge on top.

Provide 12 in. (305 mm) clearance on

top of freezer.

1-2

e. Viscosity control is set too warm. e. Contact a Taylor service technician. - - -

5. Mix in the mix cabinet is

too warm.

a. Warm mix was placed in the tank. a. Mix added to the mix tank should be

below 40°F (4.4°C).

7-1

b. The mix cabinet door was left open. b. The door must be kept closed. 6-13

c. The mix cabinet door gasket is not

sealing.

c. Repair or replace gasket.

- - -

d. Dirty mix cabinet condenser or air

filter.

d. Clean monthly.

7-2

e. The mix cabinet refrigeration

system needs adjustment.

e. Contact a Taylor service technician.

- - -

6. Mix in the mix cabinet is

too cold.

a. The mix cabinet refrigeration

system needs adjustment.

a. Contact a Taylor service technician.

- - -

7. Excessive mix leakage

from the bottom of the

door spout.

a. Worn, missing, or incorrect O-ring

on the draw valve.

a. Check the O-rings.

(Replace every 3 months.)

9-1

b. Improper lubrication on the draw

valve O-rings.

b. Lubricate properly.

6-4

8. Excessive mix leakage

into the rear drip pan.

a. Worn or missing driveshaft seal. a. Install or replace the seal. 6-1/9-1

b. Improper lubrication of the

driveshaft.

b. Lubricate properly.

6-1

c. Worn rear shell bearing. c. Contact a Taylor service technician to

replace the rear shell bearing.

- - -

d. The gearbox is out of alignment. d. Contact a Taylor service technician to

align the gearbox.

- - -

9. The driveshaft is stuck in

the gearbox coupling.

a. Rounded corners on hex end of

driveshaft or gear coupling.

a. Replace damaged component.

- - -

b. The gearbox is out of alignment. b. Contact a Taylor service technician to

align the gearbox.

- - -

Problem Probable Cause Remedy

Page

Ref.

Loading...

Loading...