CONTROLS

2-19

Models C712/C713

Controls

2

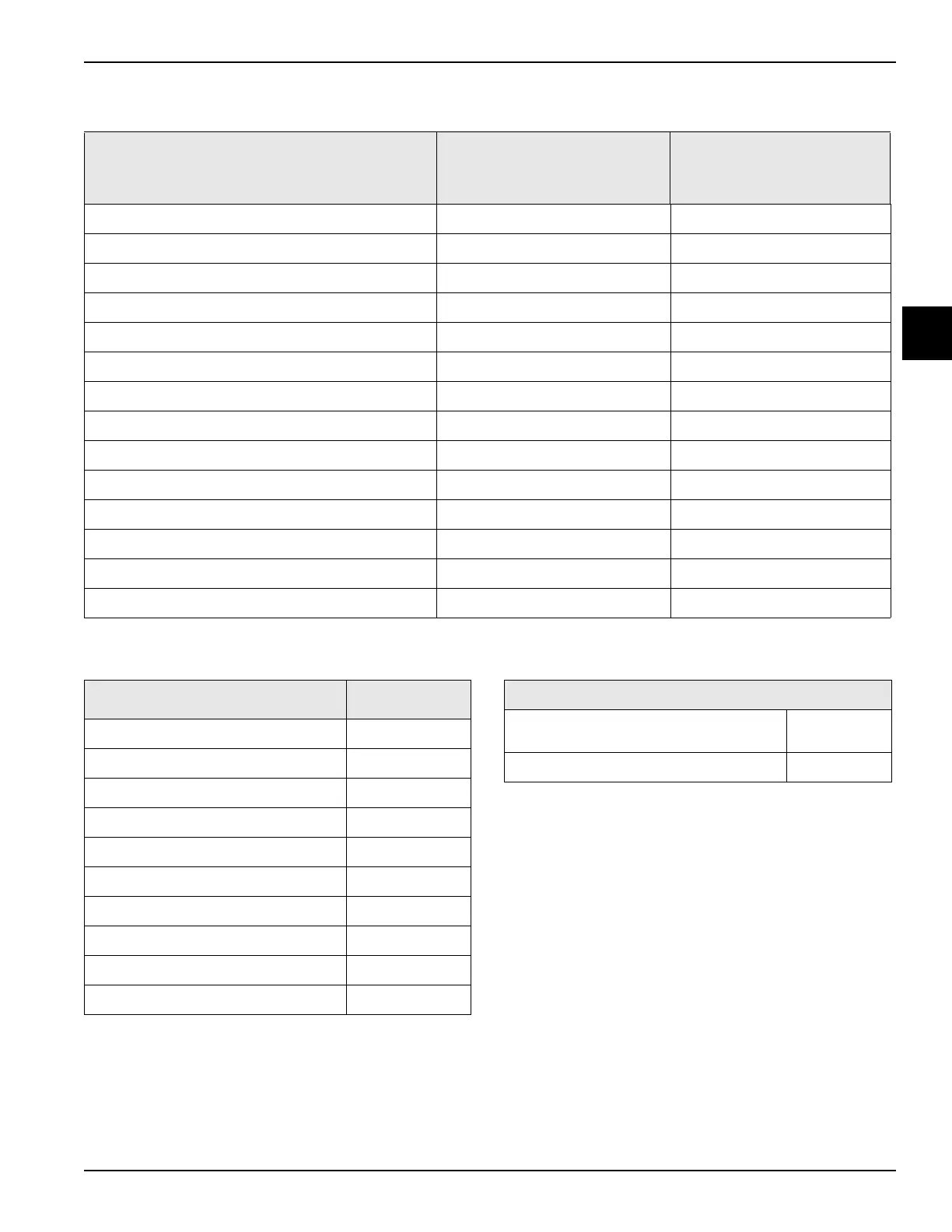

Jumper Pin Chart - UVC4

** Jumper initially installed at factory.

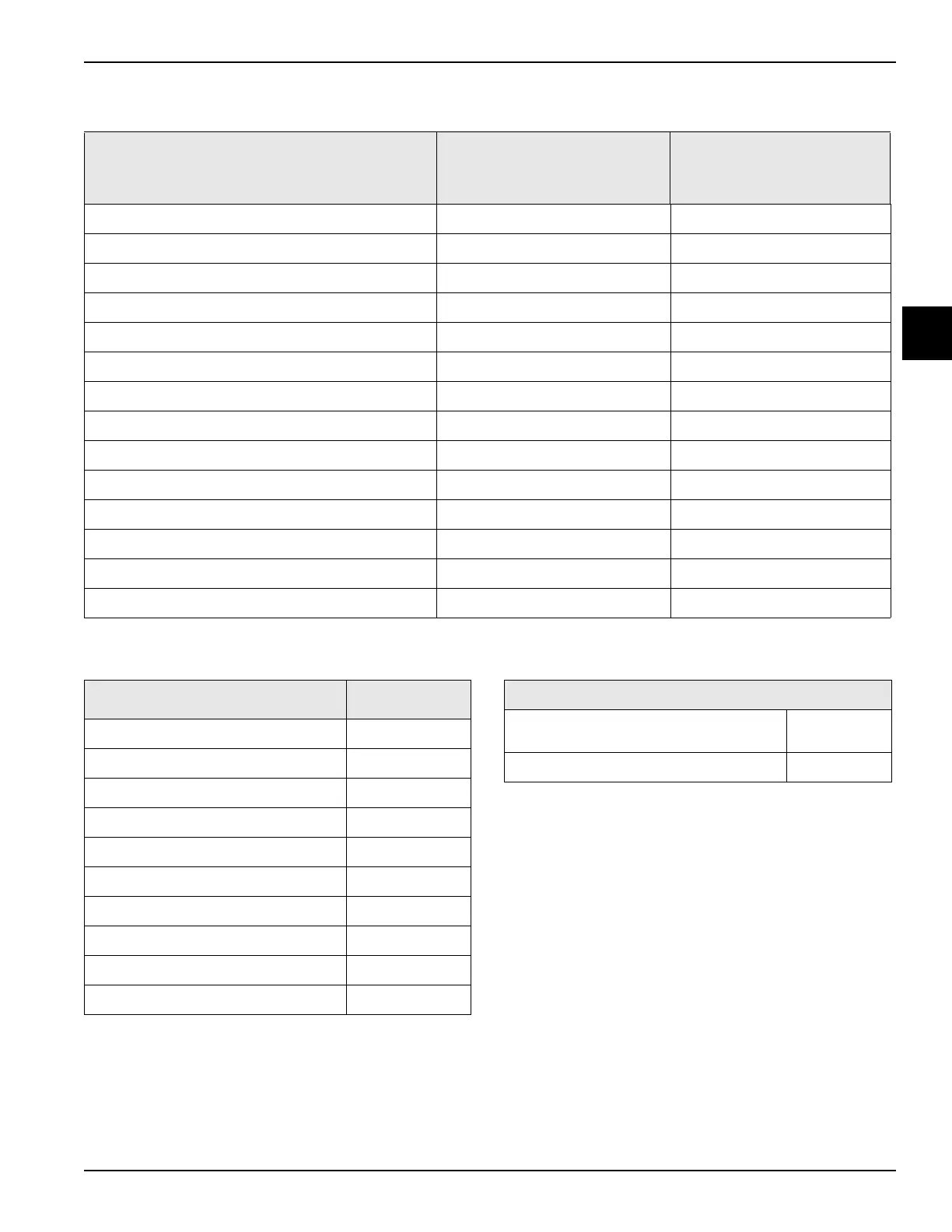

Table 2-4

** Jumper initially installed at factory.

Table 2-5

** Jumper initially installed at factory.

Table 2-6

Notes:

1. Left and right are determined while facing the front of

machine.

2. Specified feature is established when the jumper is

installed.

3. International mode (jumper removed) enables direct

use of Heat and Standby buttons and hopper

temperature display. Note: C712/C713 Standby

buttons are always enabled. C712/C713 do not have

Heat buttons.

4. Jumper should be installed on shake machines to

enable proximity sensor. It is not active on soft serve

machines; jumper can remain installed.

Feature

C712/C713

Left Interface

X59485-SER

C712/C713

Right Interface

X59485-SER

Force Brush Clean Status W2

Syrup Heater Enable W3

Open All Left Solenoids W4

Open All Right Solenoids W4

Clock/Calendar Override W5

Force Glycol Pump On

59F Fault Detection Enable W2**

Standby Stir Cycle Disable W5

Reduced Mix Low Sensitivity W6 W6

Reduced Mix Out Sensitivity W7 W7

7C/45F 90 Min. Cool Phase

Unused W1 W1

Unused

Disable Control Panel (Self Serve) J10 - 7 & 8

UVC4 Control Feature Jumper

>41F for 4 hours & >45 for 1 hr JP1 - 1 & 2**

Reserved (do not install) JP1 - 3 & 4

Domestic/International (Note 3) JP2 - 1 & 2 **

Reserved (do not install) JP3 - 1 & 2

Reserved (do not install) JP4 - 1 & 2

Proximity Sensor (Note 4) JP5 - 1 & 2**

Reserved (do not install) JP6 - 1 & 2

Reserved (do not install) JP7 - 1 & 2

Reserved (do not install) RTCK - 1 & 2

Reserved (do not install) DBGEN - 1 & 2

Personality Board

0–6 Beater Motor Amperage (do not use) A

0–12 Beater Motor Amperage B**

Loading...

Loading...