CONTROLS

2-27

Models C712/C713

Controls

2

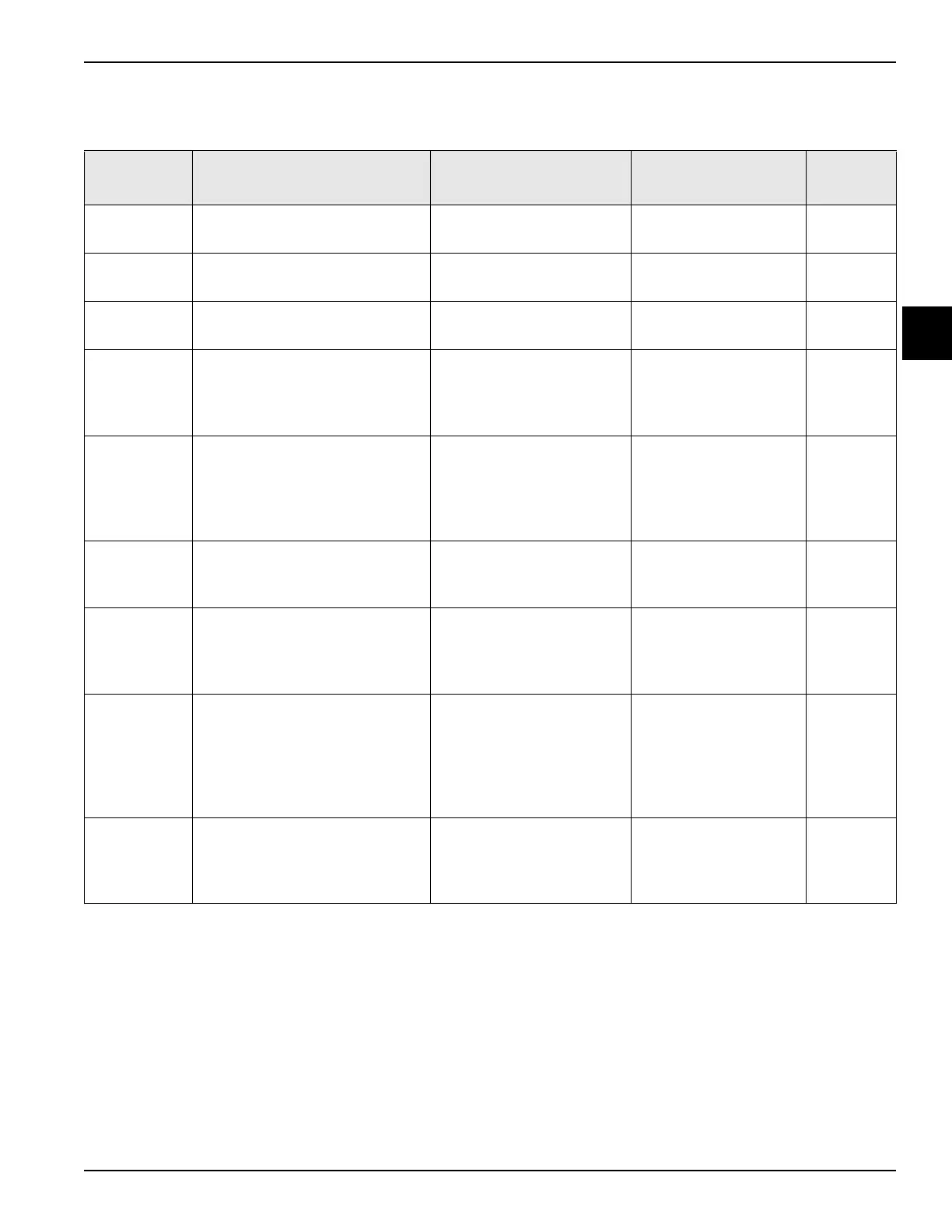

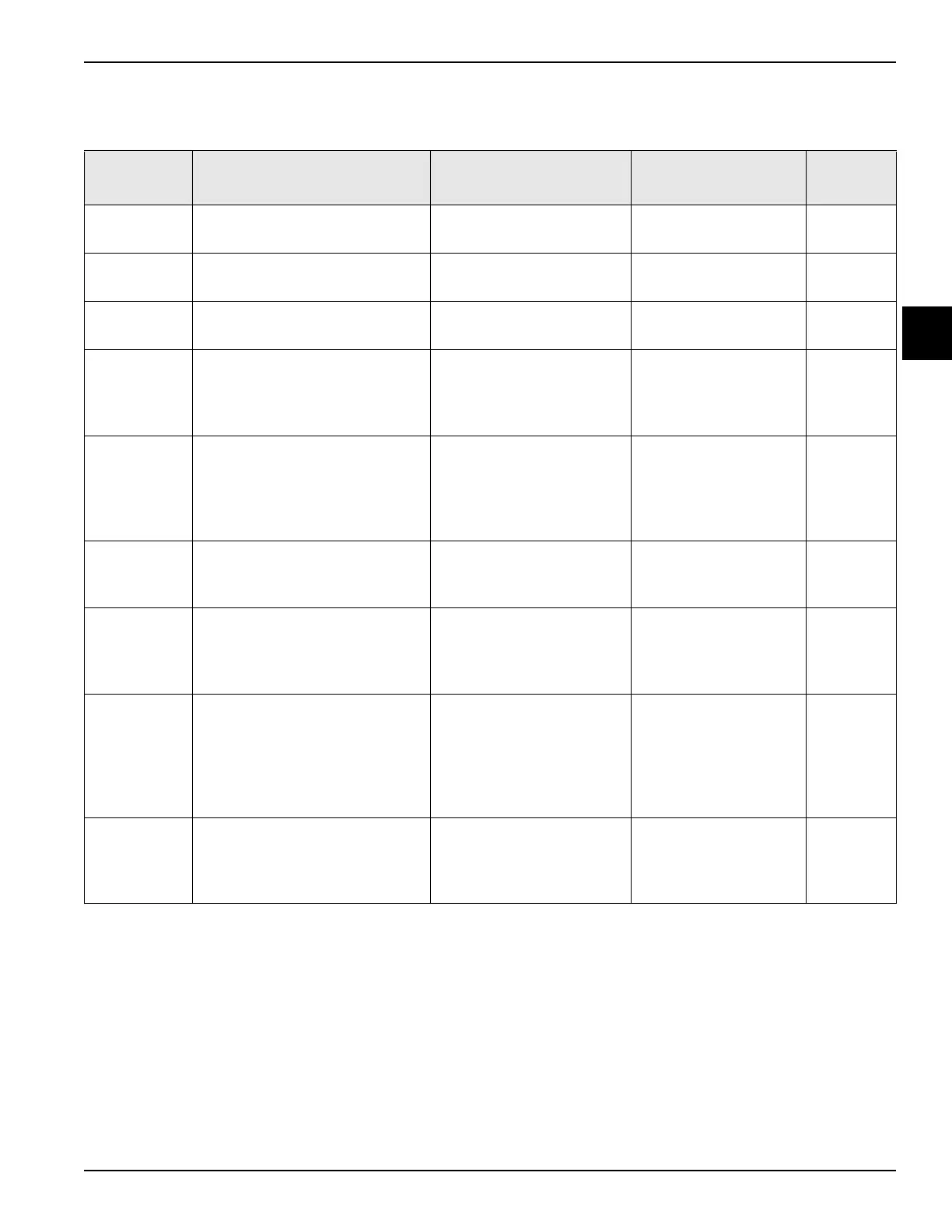

Refrigeration System Components

Comp Label Description Function Basic Operating Logic

Input/

Output

Mix Hopper 20 qt. capacity, wrapped with 40' of 5/

16” copper tubing

Storage of product mix,

evaporator.

Freezing

Cylinder

Conventional, 3.4 qt. flooded

evaporator

Freezing of product,

evaporator.

Condenser Lanced fin Cooling of compressed

refrigerant.

Fan -

Condenser

Motor A.-Fan (Blower) Provides air flow to remove

heat from condenser heat

exchanger.

On with the compressor in

Auto and Standby.

Operates for 30 sec. after

the compressor shuts off.

Output

Compressor Hermetically sealed - Copeland,

CS20

Compresses the refrigerant.

Used for barrel and hopper

cooling in Auto, Standby, and

the cooling phase of the heat

mode.

Enabled in Auto and

Standby. Off in Wash and

Off modes.

Output

AXV Automatic expansion valve for the

freezing cylinder - 046365

Controls the refrigerant flow

during the cooling of the

freezing cylinder.

Filter/Dryer Dryer-Filter-HP62-3/8 x 1/4S -

048901

This keeps moisture, dirt,

metal, and chips from entering

the refrigerant flow control

valves.

Heat Exchanger

(sub cooler)

15.25 joined length This allows the liquid

refrigerant to be cooled before

it reaches the AXV.

When the liquid is

subcooled before it

reaches the refrigerant

control, the refrigeration

effect per unit mass of

refrigerant is increased.

Receiver Accumulator - 047062 The liquid receiver is a storage

tank for liquid refrigerant.

The use of a liquid receiver

makes the quantity of

refrigerant in a system less

critical.

Loading...

Loading...