Manual code 75803707A.0708

Page 18 of 64

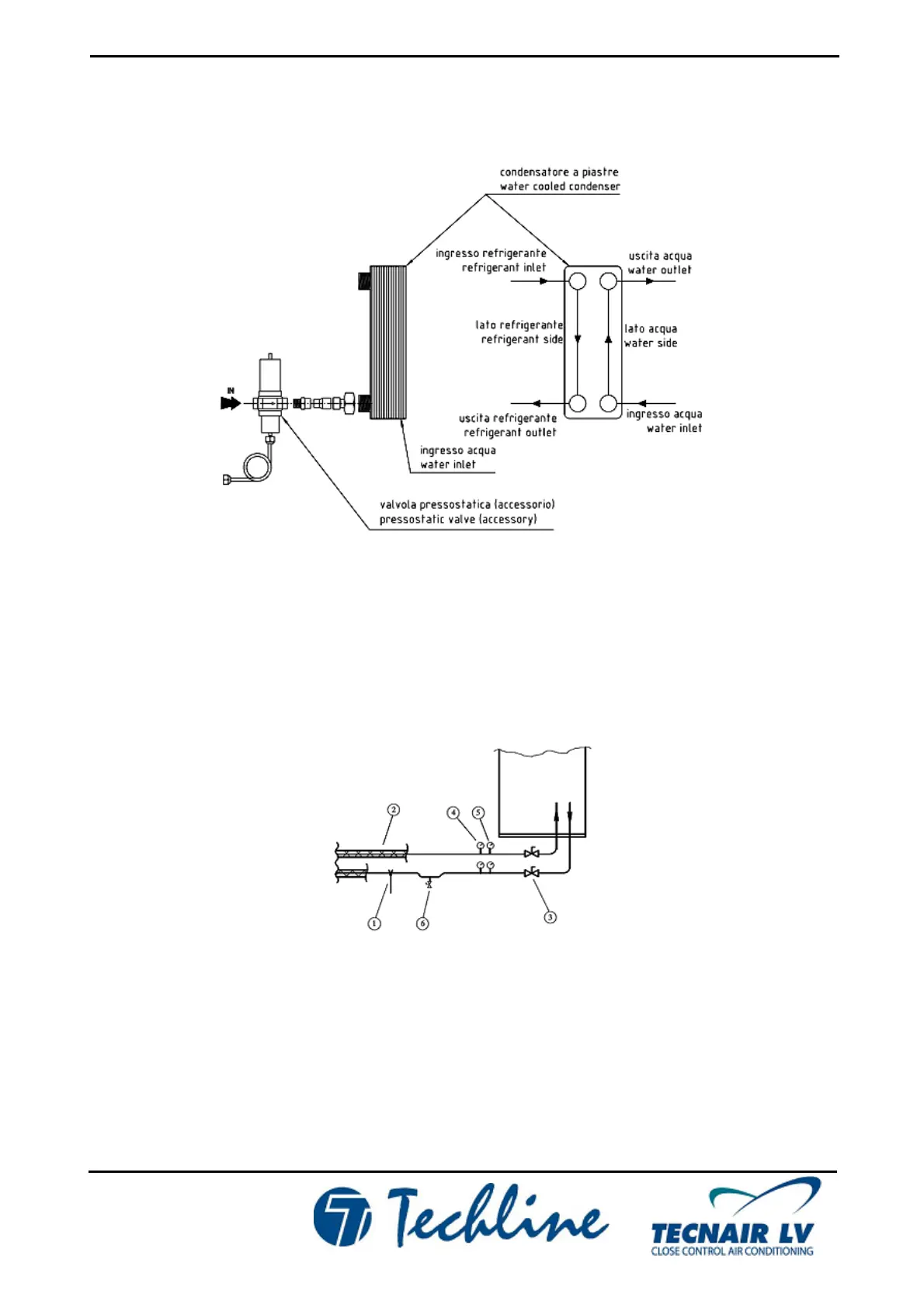

4.6.2 WATER-COOLED CONDENSERS

On machines with integral water-cooled condensers, it will be necessary to install the supply and discharge lines

to the condenser. The diameters of the pipes and the inlet and the outlet unions are indicated in the order confirmation.

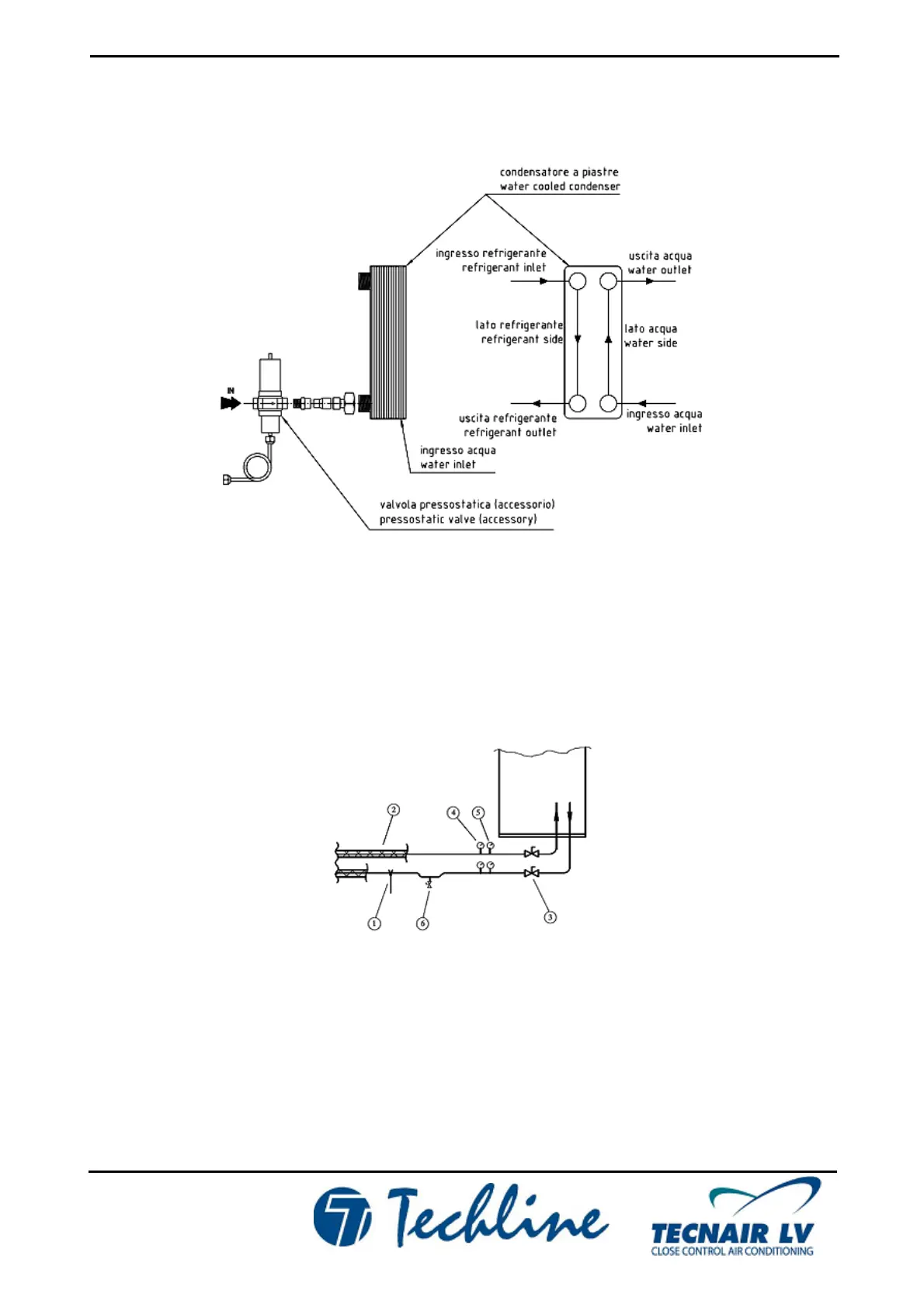

To ensure that circuit pipes are installed correctly, we recommend that the following indications are

observed:

• Use pipes made of copper or steel

• Support pipes with suitable brackets (1)

• Insulate both pipes with Armaflex type insulation (2)

• Install shut-off valves to facilitate maintenance (3)

• Install a Thermometer (4) and Pressure gauge (5) on the inlet and outlet

• Install a drain outlet in the lowest part of the circuit (6)

• Use a water/glycol solution where necessary

4.6.3 PRESSURE CONTROLLED VALVE

The pressure controlled valve (accessory) is essential when the water is supplied from a well, river or aqueduct;

however it is not necessary when the water is supplied from a water tower. In practical terms, the valve is necessary if

there is the possibility that the water temperature can fall so low during winter (e.g. below 15 degrees) that the machine’s

condensation temperature is consequently reduced too much). The valve is factory-installed on the condenser water

inlet.

If the water supply is obtained from a well or river, two filters of suitable characteristics for the type of water must

be installed in parallel, (one as backup for the other) to prevent the condenser from becoming clogged by impurities in

the water.

Loading...

Loading...