35

Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series WinCNC Manual

WinCNC

IV. Advanced Tutorials

4.1 Tool Changers

About Using The Automatic Tool Changer

When using the Automatic Tool changer, the operator may choose to drop off one tool and pick up

another tool.

Thisisusefulforlearningtoollengths,settingorigins,andoptimizingjobles.

Performing a Tool Change is a simple procedure, but one that must be done cautiously.

Before A Tool Change

Before performing a Tool Change, the operator must ensure that the current tool in the machine

hasanempty“toolpocket”inthelinearrack.

From Left to Right, the tool numbers are from 1 to 8.

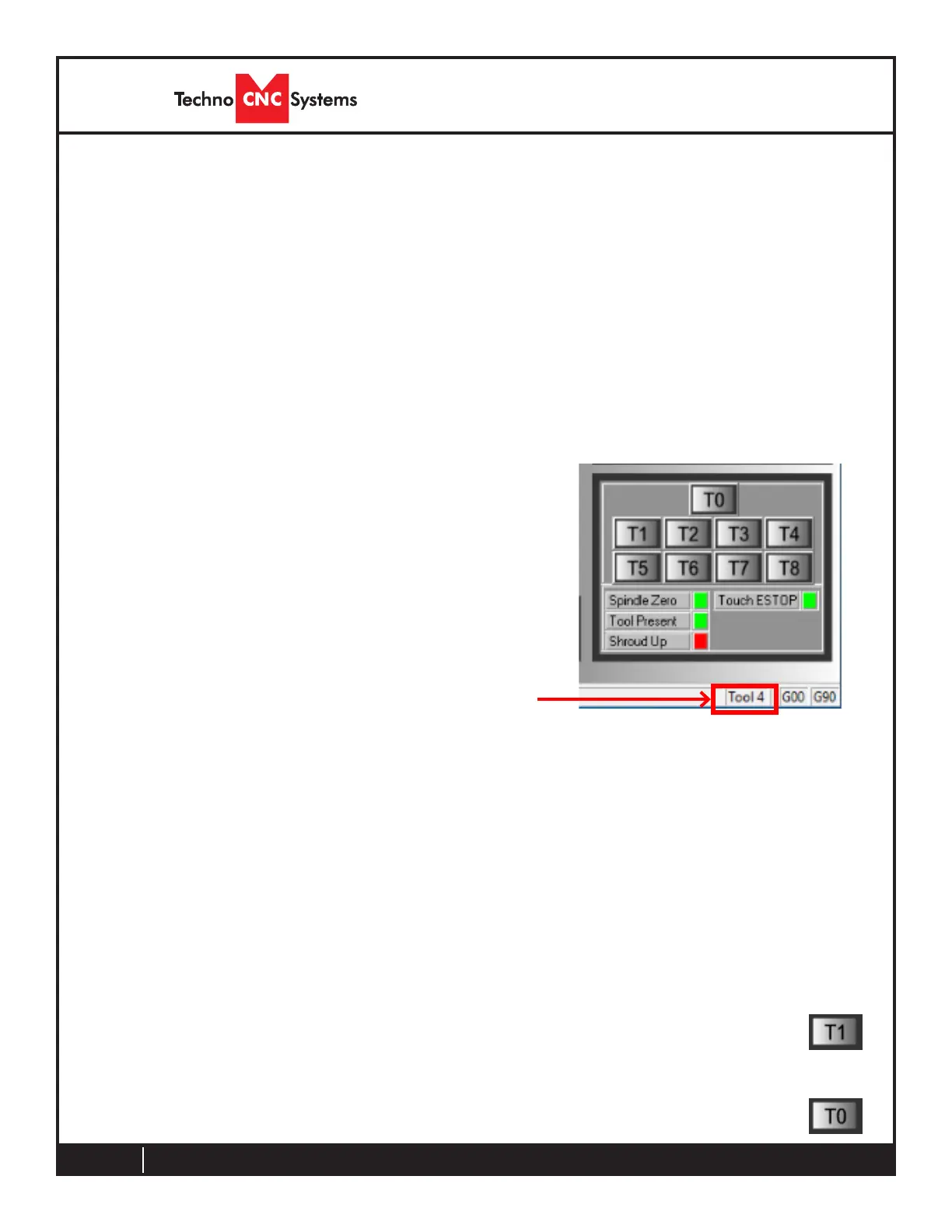

So if the machine has tool number 4, as indicated in the lower

righthandcornerofthe“ToolChangeControlArea”,thenthe

4th white clip, or pocket, from the left must be empty.

Next, the operator needs to be sure that the tool he/she wants

to pick up is in the correct pocket. If the operator wants to pick

up tool 2, then the 2nd pocket from the left must have a tool in

it.

Performing A Tool Change

Once the operator has performed the proper checks, a tool change can easily be initiated by

clickingthe“T”buttonofthetooltheoperatorwouldliketopickup.

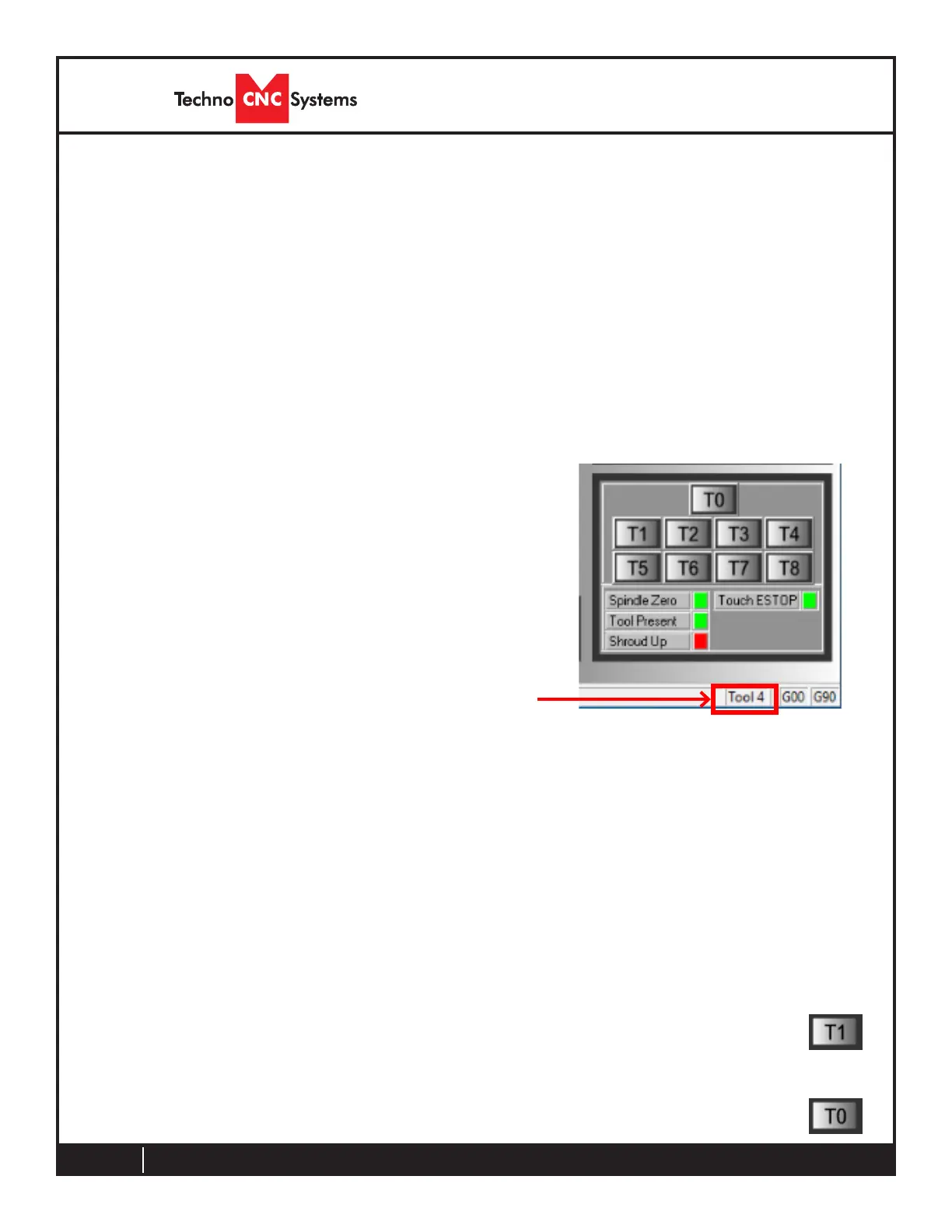

Topickuptoolnumber1,theoperatorcanpress“T1”

The machine will drop off the current tool and then pick up Tool 1

Iftheoperatorpresses“T0”,themachinewilldropoffthecurrenttoolandthenstop.

Changing Tool Number

Ifthe“ToolChangeControlArea”says“NoTool”oryouneedtoidentifythetoolinthespindle,

gototheCommandLineandtypein“L110T#”forthetoolthatyouhaveinthespindle.Press

ENTERandthe“ToolChangeControlArea”willchangetothecorrectedtoolnumber.

Loading...

Loading...