64

Parameter

Name & Function Default Unit

Setting

Range

Control

Mode

Communication

Address

RS232 RS485

Sn209

S curve speed command acceleration time setting.

200 msec

0

│

5000

S C45H 0209H

Refer Sn208

Sn210

S curve speed command deceleration time setting.

200 msec

0

│

5000

S C46H 020AH

Refer Sn208

Sn211

Speed loop Gain 1

40 Hz

10

│

1500

Pi

Pe

S

530H 020BH

Speed loop gain has a direct effect on the frequency

response bandwidth of the Speed-control loop.

Without causing vibration or noise Speed-loop-gain can

be increased to obtain a faster speed response.

If Cn025 (load Inertia ratio) is set correctly, the

speed-loop-bandwidth will equal to speed-loop-gain.

Sn212

Speed-loop Integral time 1

100

x0.2

ms

1

│

5000

Pi

Pe

S

531H 020CH

Speed loop integral element can eliminate the steady

speed error and react to even slight speed variations.

Decreasing Integral time can improve system rigidity.

The formula below shows the relationship between

Integral time and Speed loop Gain.

Sn213

Speed loop Gain 2

40 Hz

10

│

1500

Pi

Pe

S

53AH 020DH

Refer to Sn211

Sn214

Speed loop Integral time 2

100

x0.2

msec

1

│

5000

Pi

Pe

S

53BH 020EH

Refer to Sn212

Sn215

Value of zero speed

50 rpm

0

│

4500

ALL 532H 020FH

Set the zero speed range in Sn215

When the actual speed is lower than Sn215 value,

Output contact ZS is activated.

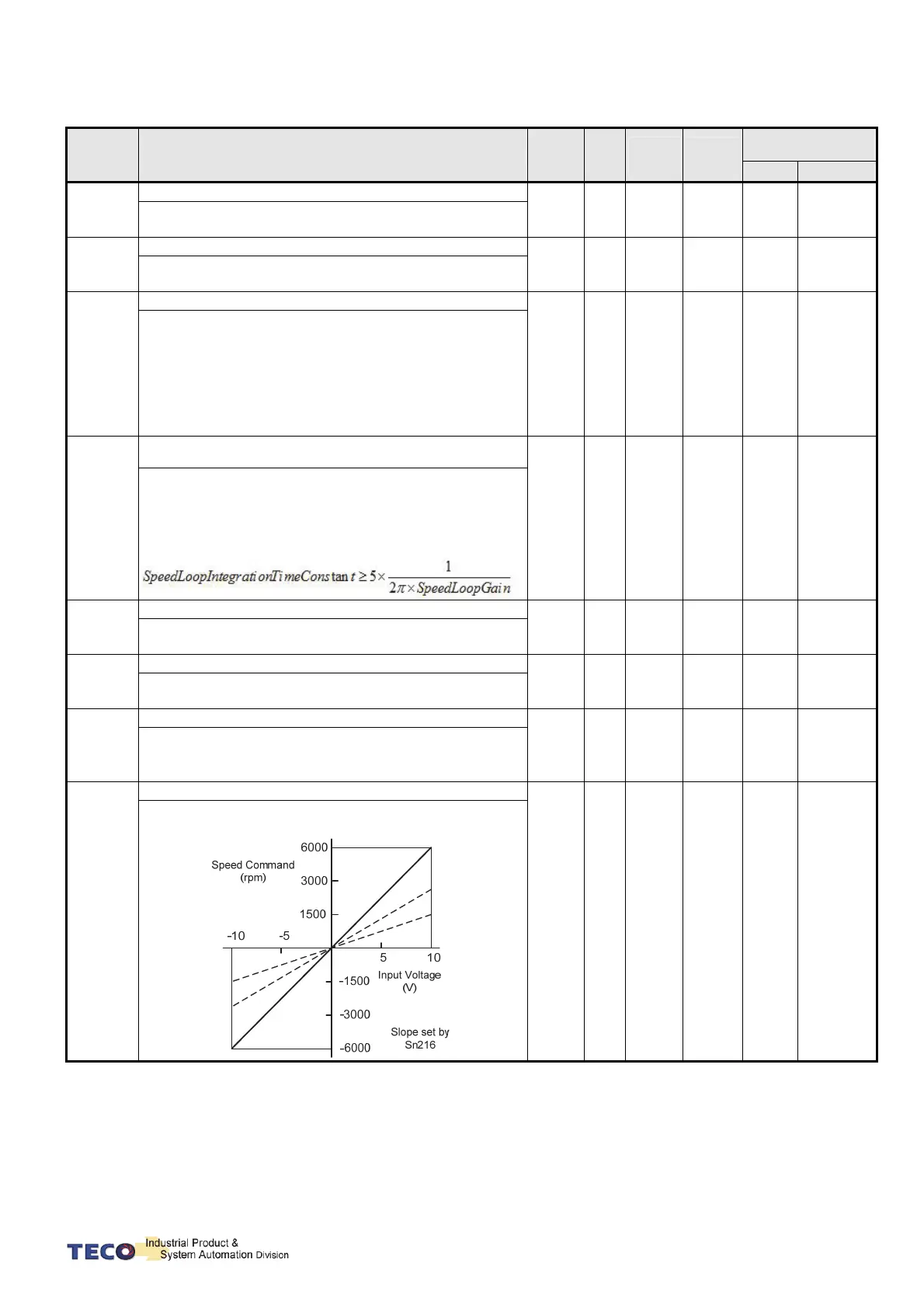

Sn216

Analog Speed Command Ratio

Rate

rpm

rpm

/10V

100

│

6000

S 533H 0210H

Slope of voltage command / Speed command can be

adjusted.

Loading...

Loading...