ME910G1 HW Design Guide

1VV0301593 Rev.7 Page 73 of 98 2021-02-02

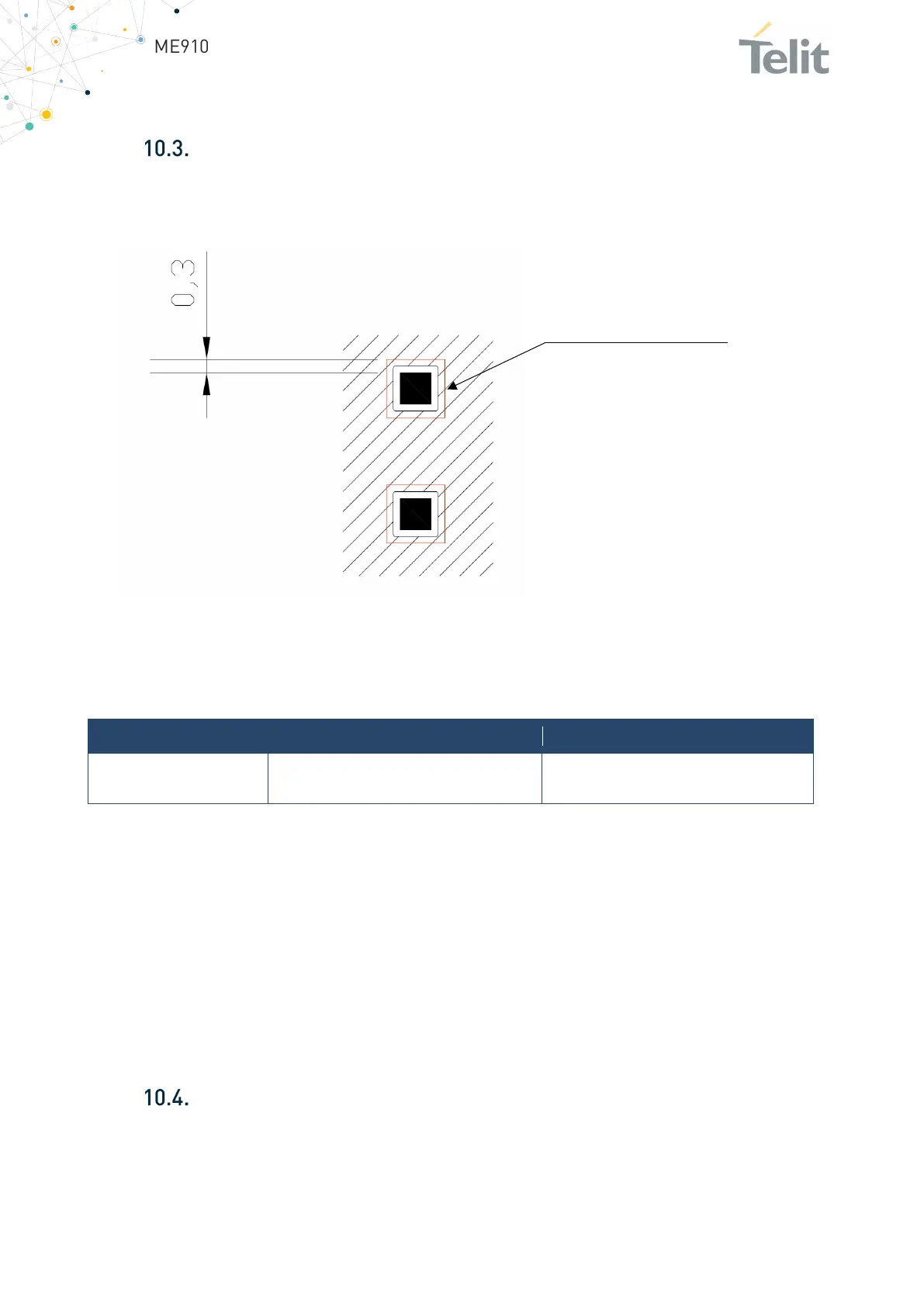

Recommendations for PCB pad dimensions

It is not recommended to place via or micro-via not covered by solder resist in an area of

0,3 mm around the pads unless it carries the same signal of the pad itself

Figure 29: Pad dimensions recommendations

Holes in pad are allowed only for blind holes and not for through holes.

Recommendations for PCB pad surfaces:

Electro-less Ni /

Immersion Au

good solder ability protection,

high shear force values

Table 33: Recommendations for PCB pad surfaces

The PCB must be able to resist the higher temperatures that occur during the lead-free

process. This issue should be discussed with the PCB-supplier. Generally, the wettability

of tin-lead solder paste on the described surface plating is better compared to the lead-

free solder paste.

It is not necessary to panel the application’s PCB, however in that case it is recommended

to use milled contours and predrilled board breakouts; scoring or v-cut solutions are not

recommended.

Thermal performance

FR4 is one of the most commonly used PCB materials, it is a flame retardant composite

material, composed by fiberglass-reinforced and epoxy laminate. One of the features of

the FR4, is to have a very low thermal conductivity. An inexpensive way to improve thermal

Inhibit area for micro-via

Loading...

Loading...