5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

24VAC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+5VDC

+12VDC

DWG No:

Sheet

of

SupersedesScale

Date:

Drawn: References

Date

ByRevisionsRev PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF). Chk: App:

TITLE:

Last Modified:

Size

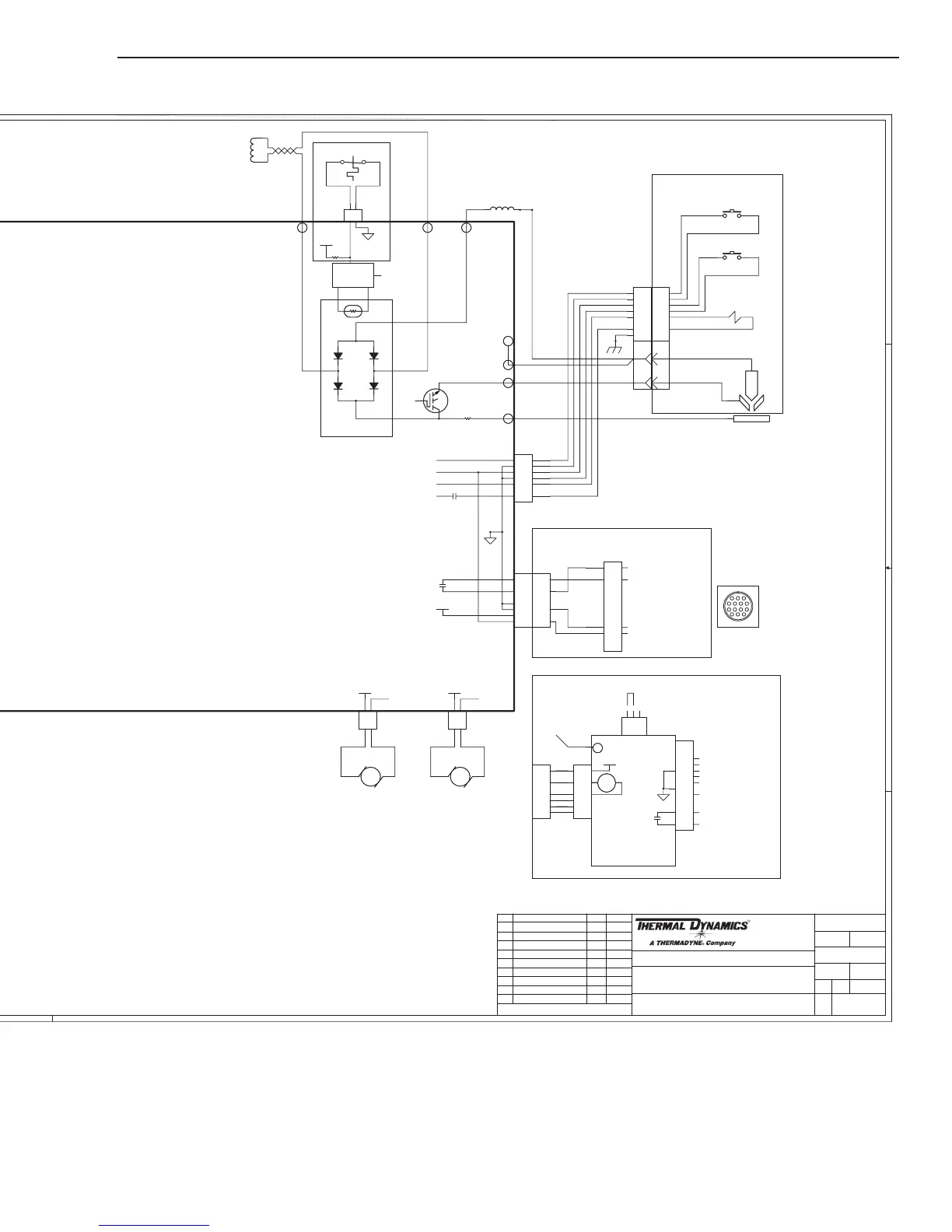

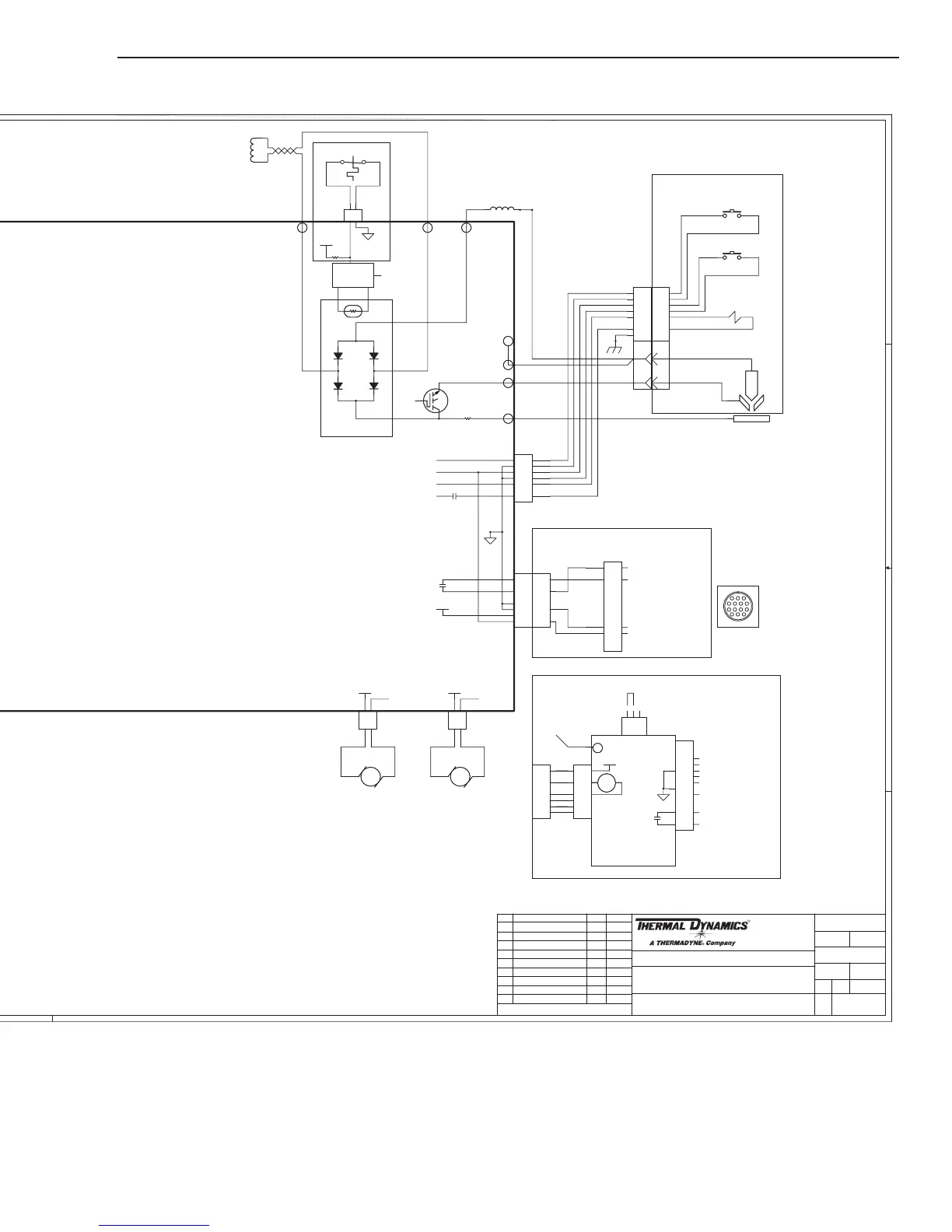

SCHEMATIC,

42X1298

Monday, March 30, 2009

1 1

16052 Swingley Ridge Road

Suite 300

St Louis, MO 63017 USA

CUTMASTER 52/82/A40/A60 230/460V

Thursday, March 27, 2008

13:16:29

THERMADYNE

C

DWG No:

Sheet

of

SupersedesScale

Date:

Drawn: References

Date

ByRevisionsRev PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF). Chk: App:

TITLE:

Last Modified:

Size

SCHEMATIC,

42X1298

Monday, March 30, 2009

1 1

16052 Swingley Ridge Road

Suite 300

St Louis, MO 63017 USA

CUTMASTER 52/82/A40/A60 230/460V

Thursday, March 27, 2008

13:16:29

THERMADYNE

C

DWG No:

Sheet

of

SupersedesScale

Date:

Drawn: References

Date

ByRevisionsRev PCB No:

Assy No:

Information Proprietary to THERMAL DYNAMICS CORPORATION.

Not For Release, Reproduction, or Distribution without Written Consent.

NOTE: UNLESS OTHERWISE SPECIFIED -

1. RESISTOR VALUES ARE EXPRESSED IN OHMS, 1/4W 5%.

2. CAPACITOR VALUES ARE EXPRESSED IN MICROFARADS (uF). Chk: App:

TITLE:

Last Modified:

Size

SCHEMATIC,

42X1298

Monday, March 30, 2009

1 1

16052 Swingley Ridge Road

Suite 300

St Louis, MO 63017 USA

CUTMASTER 52/82/A40/A60 230/460V

Thursday, March 27, 2008

13:16:29

THERMADYNE

C

AB

24 VAC RETURN

J1

80

PCB4

AUTOMATION

INTERFACE PCB

OVER PRESSURE

INTERNAL ERROR

SHORTED TORCH

CONSUMABLES MISSING

START ERROR

PARTS IN PLACE

INPUT POWER

UNDER PRESSURE

81

ERROR IND FAULT

PCB3

8

9

82

7A

}

OK-TO-MOVE

OK-TO-MOVE

83

OK TO MOVE

1TORCH

Q2

PRIMARY POWER CONNECTIONS:

3PH USE L1,L2,L3 & GND

REMOVE JUMPER BETWEEN L2 TO L3

1PH USE L1, L2 & GND -

INSTALL JUMPER BETWEEN L2 TO L3

*

5

6

}

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

29

34

35

36

37

38

39

}

E64

E35

78

79

INPUT VOLTAGE SELECTOR

(Closed for 230VAC input)

-

+

-V_OUT_SIGNAL

/TIP_VOLTS

/TIP_SENSE

/460V_IN

/230V_IN

CUR_SET

/RAR (RAPID AUTO RESTART)

/INRUSH

/W1_ON

/SHDN

/TORCH_SOLENOID

/SOLENOID_ON

/OK_TO_MOVE

/FAN_ON

/LATCH_ACTIVE

/TORCH_SWITCH

/PIP

AC_ON

CSR

/TORCH_SOLENOID_DETECT

/OVERTEMP

V_IN

+12VDC

+12VDC

COMMON

COMMON

MAIN_PCB_ID

460_IN

+3.3VDC

TXD

RXD

COMMON

D

M-L

M-L

M-L

L-M

L-M

L-M

L-M

L-M

L-M

L-M

L-M

L-M

L-M

L-M

L-M

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

M-L

L-M

M-L

M-L

L-M

M-L

FULL FEATURED AUTOMATION INTERFACE PCB OPTION

CNC INTERFACE STANDARD ON A40 & A60 UNITS

CNC INTERFACE OPTIONAL ON CM52 & CM82 UNITS

(+)

*

L1

L2

L3

L4

T1

T2

T3

T4

* CM52 & A40

C3 & C5 not installed

/PIP

PCB2

/SOLENOID

Q1

PRIMARY

AC INPUT

/START

PCB1

NAFNAF

24VAC RETURN

ATC CONNECTOR

/FAN

/FAN

24VAC SUPPLY

40 PIN RIBBON CABLE SIGNALS

460_IN

LATCH

SET

RUN

RAR

40 CIRCUIT

RIBBON CABLE

}

MAX

90

85

80

75

70

65

MIN

/460

/230

J2

7

JUMPER

D1

To configure DIVIDED ARC VOLTS signal output

No jumper installed for ARC VOLTS /16.67

Jumper pins 1 & 2 for ARC VOLTS / 50

Jumper pins 2 & 3 for ARC VOLTS / 16

L1

L2

L3

GND

K1

D C

To -V OUT 1

on PCB1

}

/START / STOP

* *

AIR

INLET

FILTER

}

REGULATOR

INTRO ECO B534

DIVIDED ARC VOLTS

(5A @250VAC / 30VDC)

SOLENOID

VALVE

/START / STOP

TP1

TP2

TP3

TP4

TP5

TP6

TP7

(+)

ATC

MAIN PCB ASSY

LOGIC PCB

(-)

(W/ 100K IN SERIES (2))

INPUT CAPACITOR PCB

(-)

GAS CONTROL

*

ARC VOLTS

GND

+12 VDC

+5 VDC

3.3 VDC

0.v - 5.0 VDC / 0-100PSI

1.8 VDC

POT. DEMAND

J2 PINOUT

13

47

811

1214

TEST POINTS

GND1

GND2

GND3

+12V1

48V1

I_DMD_1

TIP_SEN

COMMON

COMMON

COMMON

+12 VDC SUPPLY

+48 VDC SUPPLY

CURRENT DEMAND

TIP DRAG SENSE

TEST POINTS

(Sink 50mA @12VDC)

AUTOMATION

TORCH SOLENOID

PRESSURE

TRANSDUCER

0-100PSI / 0-4.5VDC

INRUSH

RESISTORS

/INRUSH

/OVERTEMP

TEMP

CIRCUIT

D3

CM82 / A60 ONLY

3.3VDC

TXD

RXD

D

SERIAL PORT

BIAS

SUPPLY

RWH

AA

RWH 07/23/07

AB

MNC 04/23/08ECO B890

AC

MNC 05/09/08

ECO B855

AD

MNC 10/03/08ECO B1159

AE

RWH 03/31/09

ECO B1357

SEC1SEC1

WORK1WORK1

Q5

PILOT IGBT

Q5

PILOT IGBT

J1J1

1

2

3

4

5

6

7

8

CHOKE1CHOKE1

PRI 2 PRI 2

D1D1

J3J3

1

2

3

NTCNTC

J3J3

1

2

3

W1W1

K3K3

+

C1-C4*

+

C1-C4*

J3J3

1

2

3

MTH1MTH1

J4J4

1

2

3

4

5

W1W1

MOT1MOT1

+ -

7070

AC3AC3

9090

1

2

3

P10P10

1

2

3

4

5

6

7

8

J1J1

1

2

3

4

5

6

7

8

MTH4MTH4

TIP1TIP1

J7J7

1

2

K6K6

6565

PRI 1 PRI 1

J9J9

1

2

3

4

5

6

7

DCDC

MOT2MOT2

+ -

7575

MTH7MTH7

TS1TS1

SW1SW1

1 3

2 4

P10P10

1

2

3

4

5

6

7

8

J1J1

1

2

3

4

5

K1K1

PRI 4 PRI 4

WORKWORK

8080

SEC2SEC2

OVERTEMPOVERTEMP

E1E1

8585

AC2AC2

Current ControlCurrent Control

L1L1

MTH3MTH3

MTH5MTH5

J3J3

1

2

K1K1

D78 CSRD78 CSR

J8J8

1

2

J6J6

1

2

ERRORERROR

D59 PCRD59 PCR

MTH6MTH6

MAXMAX

SW2SW2

J5J5

1

2

3

J11J11

1

2

T1T1

J2J2

2

3

4

5

6

7

8

9

10

11

12

13

14

1

-V OUT 1-V OUT 1

AC1AC1

TORCH SWITCHTORCH SWITCH

MTH2MTH2

MTH8MTH8

GASGAS

ELECTRODE1ELECTRODE1

K1-K4K1-K4

J10J10

3

5

6

7

8

1

2

4

PRI 3PRI 3

ACAC

K4K4

K5, K6K5, K6

+

C5-C8*

+

C5-C8*

J12J12

1

2

3

J2J2

2

3

4

5

6

7

8

9

10

11

12

13

14

1

K2K2

SOL1SOL1

PIP SWITCHPIP SWITCH

1

2

3

4

5

6

7

8

K1K1

MINMIN

K5K5

A-09131_AA

A-09131_AA

Loading...

Loading...