cutskill 35A

GENERAL INFORMATON 1-2 June 30, 2009

NOISE

Noise can cause permanent hearing loss. Plasma arc processes can

cause noise levels to exceed safe limits. You must protect your ears

from loud noise to prevent permanent loss of hearing.

• To protect your hearing from loud noise, wear protective

ear plugs and/or ear muffs. Protect others in the work-

place.

• Noise levels should be measured to be sure the decibels

(sound) do not exceed safe levels.

• For information on how to test for noise, see item 1 in Sub

-

section 1.03, Publications, in this manual.

PLASMA ARC RAYS

Plasma Arc Rays can injure your eyes and burn your skin. The

plasma arc process produces very bright ultra violet and infrared

light. These arc rays will damage your eyes and burn your skin if

you are not properly protected.

• To protect your eyes, always wear a welding helmet or shield.

Also always wear safety glasses with side shields, goggles

or other protective eye wear.

• Wear welding gloves and suitable clothing to protect your

skin from the arc rays and sparks.

• Keep helmet and safety glasses in good condition. Replace

lenses when cracked, chipped or dirty.

• Protect others in the work area from the arc rays. Use protec

-

tive booths, screens or shields.

• Use the shade of lens as suggested in the following per

ANSI/ASC Z49.1:

Minimum Protective Suggested

Arc Current Shade No. Shade No.

Less Than 300* 8 9

300 - 400* 9 12

400 - 800* 10 14

*These values apply where the actual arc is

clearly seen. Experience has shown that lighter

filters may be used when the arc is hidden by

the workpiece.

LEAD WARNING

This product contains chemicals, including lead, or otherwise

produces chemicals known to the State of California to cause

cancer, birth defects and other reproductive harm. Wash hands after

handling. (California Health & Safety Code § 25249.5 et seq.)

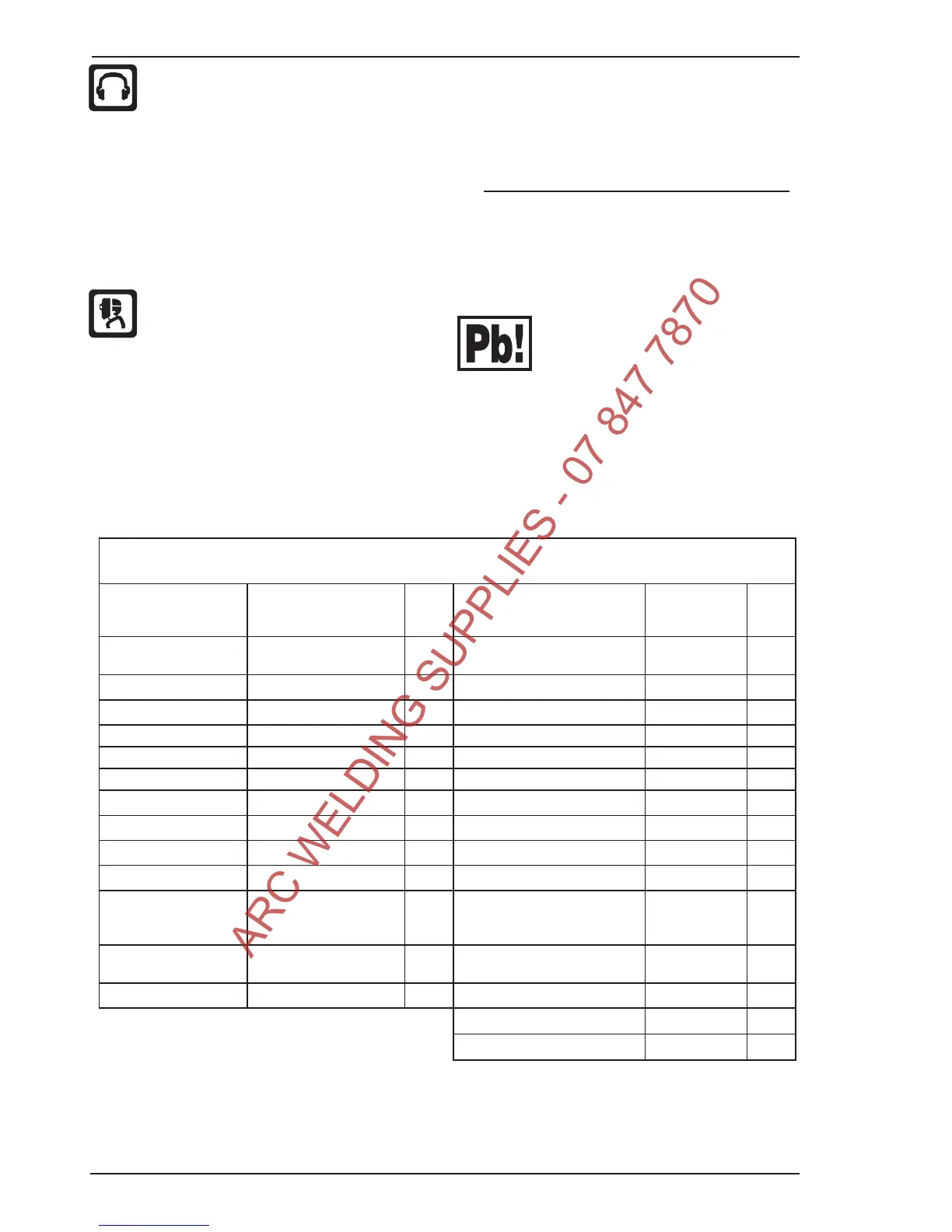

Eye protection fi lter shade selector for welding or cutting

(goggles or helmet), from AWS A6.2-73.

Welding or Cutting

Operation

Electrode Size

Metal Thickness

Filter

Shade

Welding or Cutting

Operation

Electrode Size

Metal Thickness

Filter

Shade

Torch soldering 2

Gas metal-arc

welding (MIG)

Torch brazing 3 or 4 Non-ferrous base metal All 11

Oxygen Cutting Non-ferrous base metal All 12

Light Under 1 in., 25 mm 3 or 4 Gas tungsten arc welding All 12

Medium 1 to 6 in., 25-150 mm 4 or 5 (TIG) All 12

Heavy Over 6 in., 150 mm 5 or 6 Atomic hydrogen welding All 12

Gas welding Carbon arc welding All 12

Light Under 1/8 in., 3 mm 4 or 5 Plasma arc welding

Medium 1/8 to 1/2 in., 3-12 mm 5 or 6 Carbon arc air gouging

Heavy Over 1/2 in., 12 mm 6 or 8 Light 12

Shielded metal-arc

welding

(stick) electrodes

Under 5/32 in., 4 mm 10 Heavy 14

5/32 to 1/4 in.,

4 to 6.4 mm

12 Plasma arc cutting

Over 1/4 in., 6.4 mm 14 Light Under 300 Amp 9

Medium 300 to 400 Amp 12

Heavy Over 400 Amp 14

Loading...

Loading...