Distributed by:

Ingersoll Rand’s Climate Solutions sector delivers energy-effi cient HVACR solutions for

customers globally. Its world class brands include Thermo King, the leader in transport

temperature control and Trane, a provider of energy effi cient heating, ventilating and air

conditioning systems, building and contracting services, parts support and advanced controls

for commercial buildings and homes.

SB-210+

Additional text information

to be placed here

TK 5XXXX-X-PL

TK 60275-4-MM

©2012 Ingersoll Rand Company

Printed in U.S.A.

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Distributed by:

SB-210+

Additional text information

to be placed here

TK 5XXXX-X-PL

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Additional text information

Distributed by:

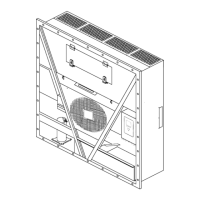

MAGNUM +

TK 60275-4-MM (Rev. 3, 08/15)

314 West 90th Street

Minneapolis, MN 55420

Direct (952) 887-2200

Thermo King Corporate

Maintenance Manual