TW 230VTR

8 / 65

OPERATING INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

TW 230VTR, Tracked Hydraulic Fed Chipper, 35hp 1498cc Diesel Engine

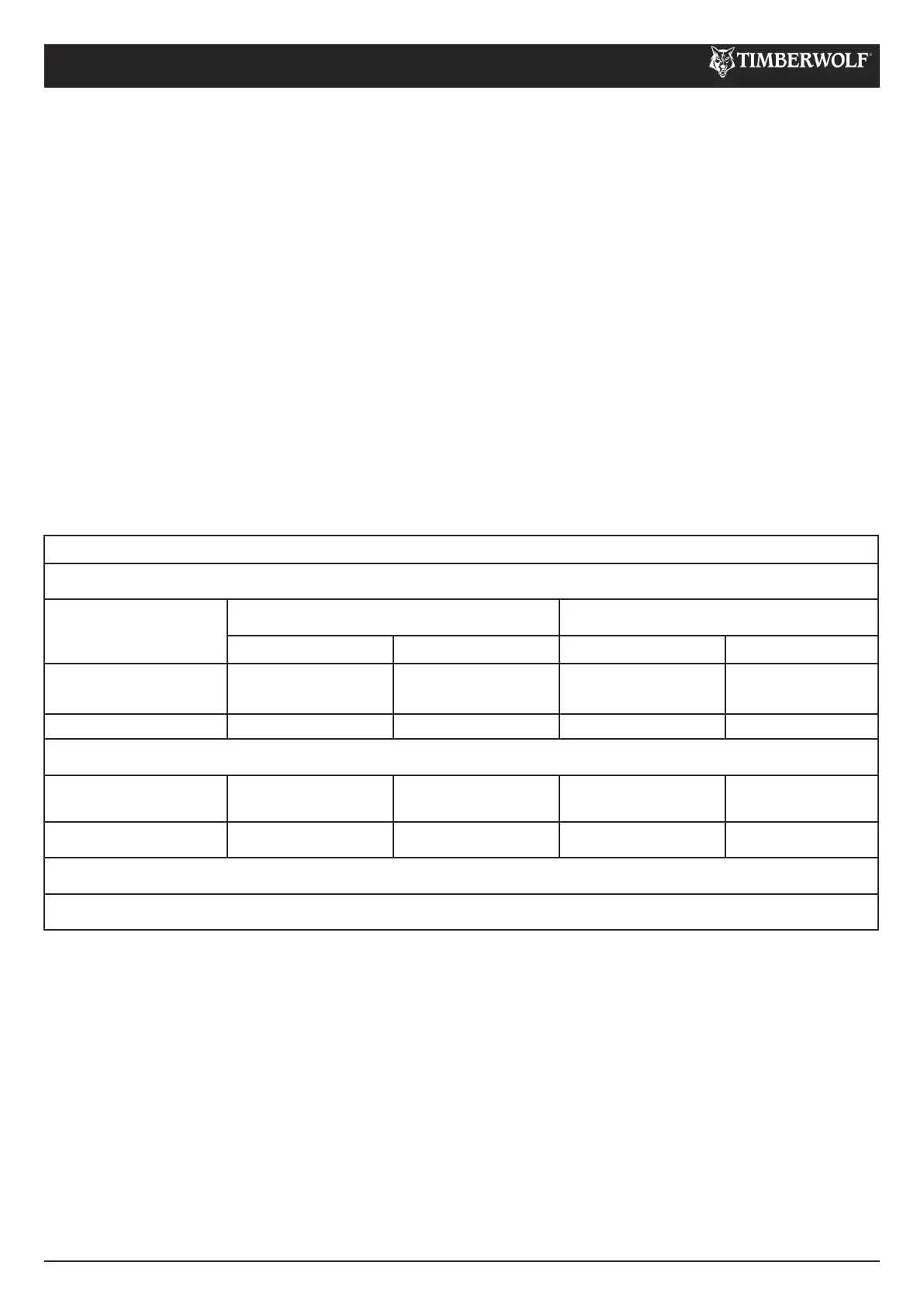

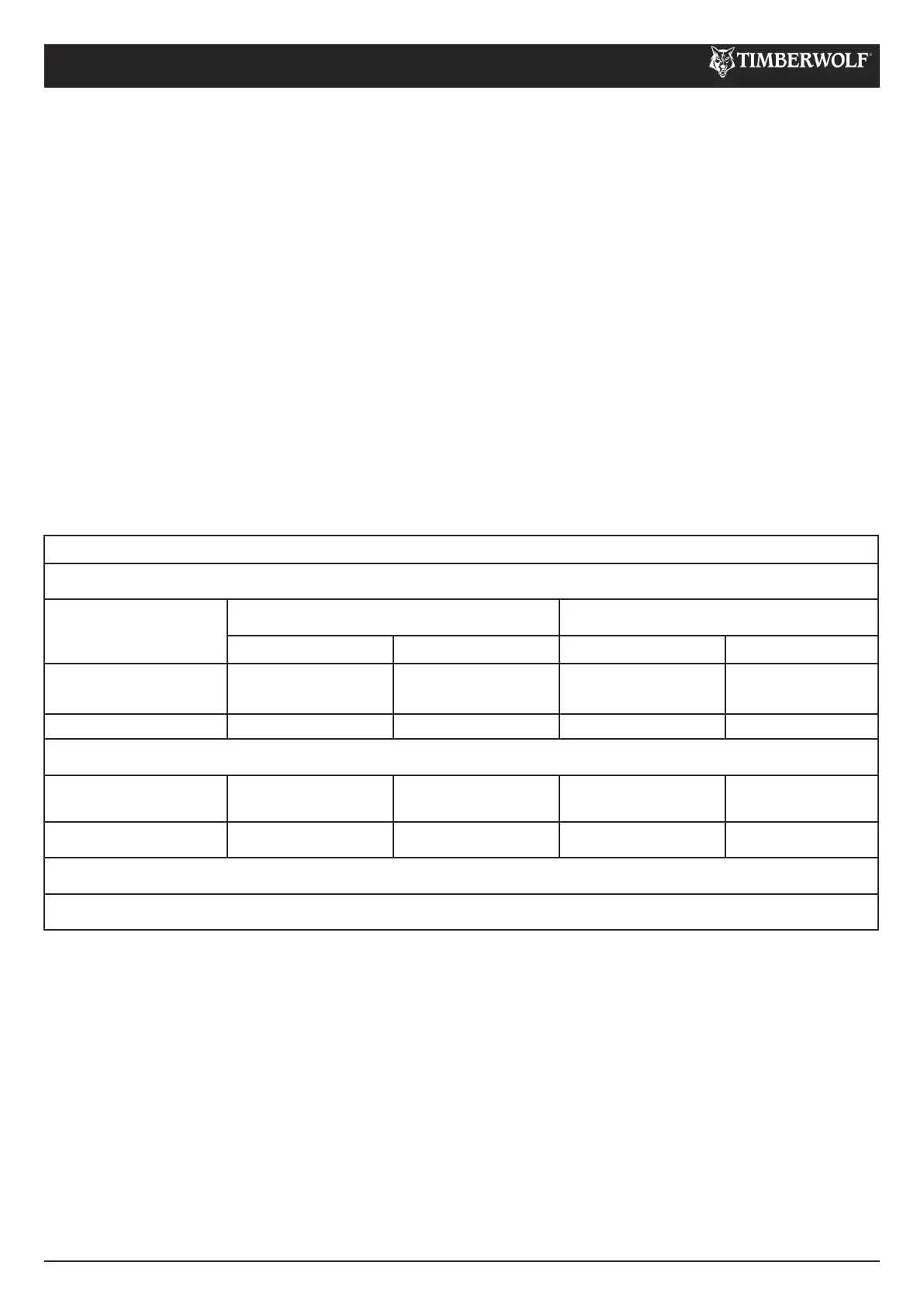

Declared vibration emission value in accordance with BS EN 12096:1997

Whole Body Vibrations (m/s

2

)

Hand Arm Vibrations (m/s

2

)

Speed 1 (2.5 kph) Speed 2 (5 kph) Speed 1 (2.5 kph)

Speed 2 (5 kph)

Measured vibration

emission value a

2.14 2.39 4.77

5.89

Uncertainty K*

0.85 0.96 2.38

2.36

Values determined when standing on driver’s platform tracking over soft grassy ground.

Measured vibration

emission value a

2.71 2.92 5.45

6.82

Uncertainty K*

1.09 1.17 2.18

2.73

Values determined when standing on driver’s platform tracking over hard paved ground.

*K value calculated according to provisions in BS EN 12096:1997

VIBRATION DATA

This data is provided to enable assessment of vibration exposure, when the machine is operated in the modes

described. Please refer to local Health & Safety Regulations to determine the daily exposure action and limit values.

RECOMMISSIONING AFTER STORAGE

Ensure machine is stable. •

Remove all guards and check all fasteners. If necessary, •

retighten as described within this manual.

Ensure discharge tube is correctly fastened, free of •

objects or blockages and rotates around its pivot

without being directed to face the point of operation

(danger zone).

Ensure feed funnel is free from foreign objects e.g. •

tools and clothing.

Lower and raise feed funnel into its open and closed •

positions to confirm functionality.

Check fuel and hydraulic fluid levels within engine and •

reservoir and top up accordingly. *

Inspect all internal parts e.g. drive belts, taper locks •

and shaft keyways.

Check belt tension as described within this manual. •

Inspect cutting blades to confirm they are sharp and •

suitable for use.

Re-connect the battery to its positive and negative •

terminals.

Undertake electrical diagnostic continuity check, to •

confirm circuit is complete.

Re-lubricate all grease pipes. Remove pipes and bleed •

the system prior to use, if necessary. *

Follow daily checks before starting, as described within •

this manual.

Start the machine. •

Run for 15 minutes at half throttle, prior to any cutting •

activity, to clear the combustion engine. Once

complete, bring the machine onto full throttle for a

further 5 minutes.

*Storage fluids should be replaced, DO NOT USE old

stagnate fluids.

Loading...

Loading...