23 / 65

SERVICE INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

TW 230VTR

CHECKING THE RUBBER TRACKS

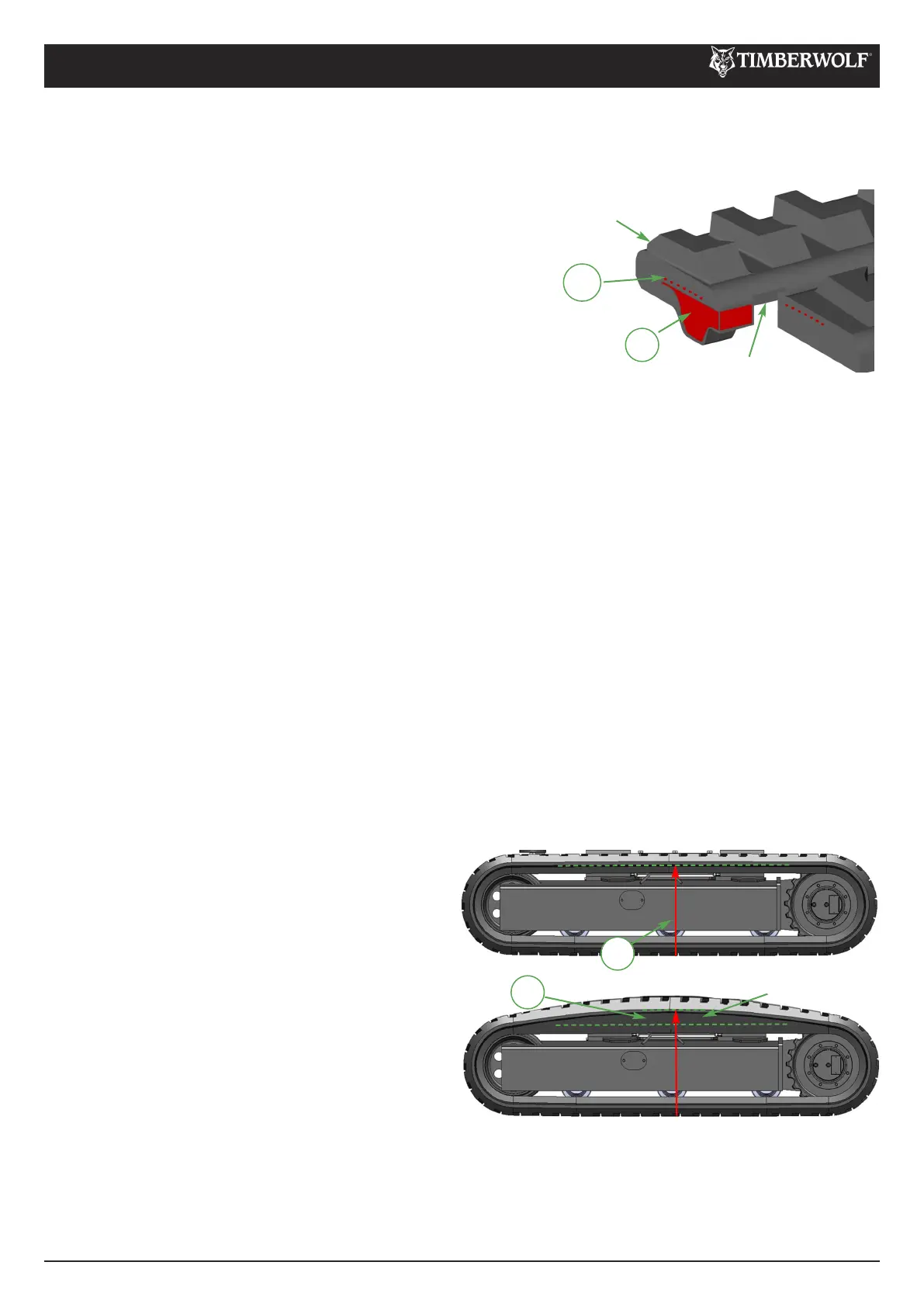

The structure of the rubber track is shown in this diagram. The

steel cables (1) and metal core (2) are embedded in the rubber.

There are many ways in which rubber tracks may be damaged.

Some of these are terminal for the tracks, others are only

cosmetic.

Breakages of steel cables and metal cores

Excess track tension can cause steel cables to break. This may be

caused by:

Stones or foreign matter accumulating between the track •

and the undercarriage frame.

The track slipping off its guide system. •

Extreme friction such as rapid changes in direction. •

Improper contact between track and sprocket. •

Operation on sandy terrain.•

Fatigue cracks and abrasion

Cracks at the base of the carved profiles are caused by rubber fatigue due to bending.

Cracks and bends on the edge of the rubber are caused by manoeuvring the track on concrete edges and curbs.

Cracks and abrasions in the rubber on the guide roller paths are caused by compression fatigue of the rubber due to the

weight of the wheel combined with operation on sandy terrain or repeated sudden changes in direction.

Abrasion of the carved profile may be caused, in particular, by rotation on concrete or gravel surfaces or hard surfaces.

Cracks on the outside surface of the track are often due to contact with gravel, sharp stones and sharp materials such as

sheet metal, nails and glass.

Cracks on the inside surface of the circumference and on the edge of the rubber are caused by contact between track

and the undercarriage structure or with sharp concrete edges.

These methods of damage are progressive. The track can continue to be used until wear exposes the metal cores. If

this exposure extends for more than half of the circumference of the track then it is time to replace the track, even

though it can still be used.

SPROCKET HOLE

CARVED

PROFILE

1

2

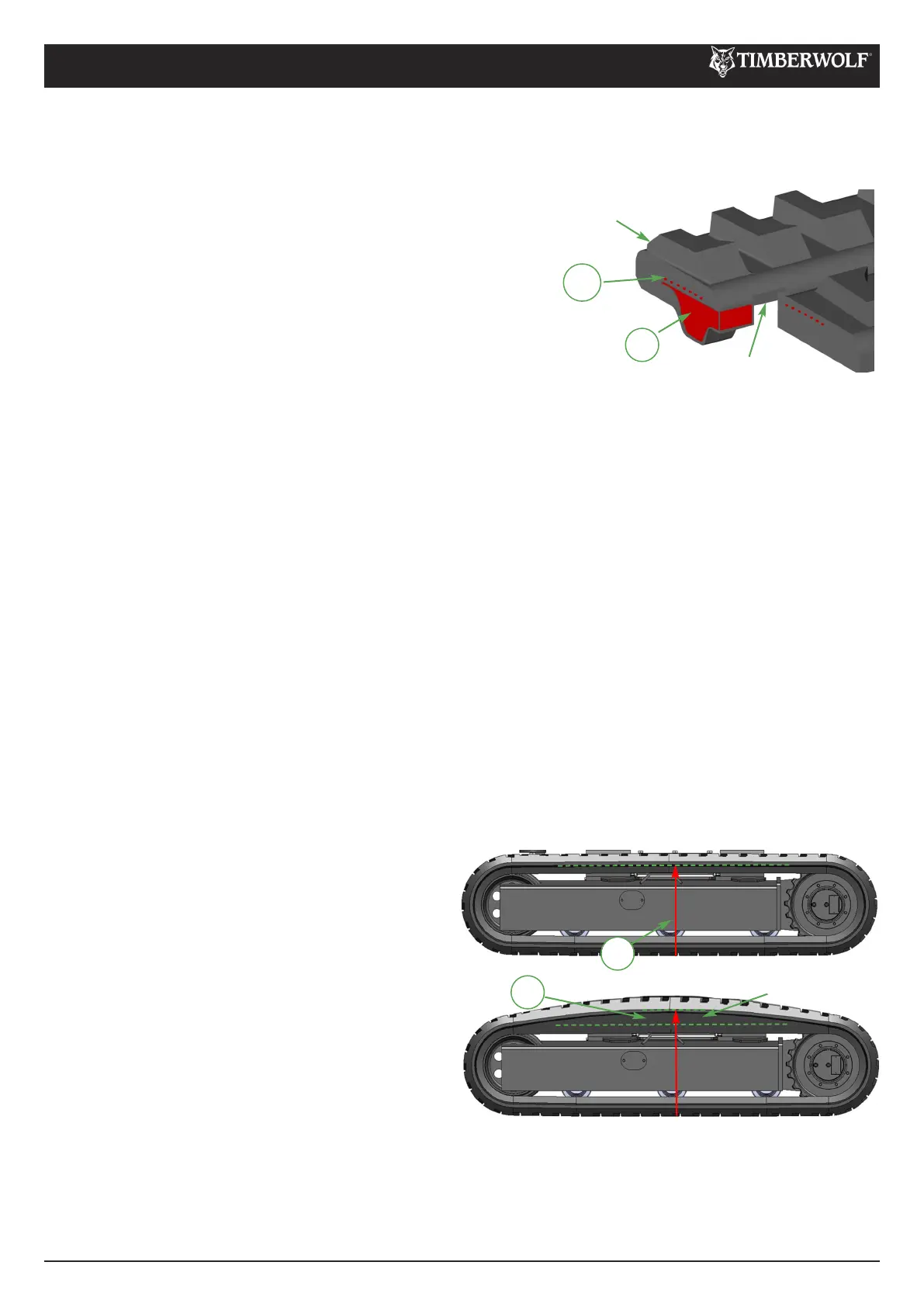

CHECKING TRACK TENSION

Stop your machine on a flat and solid surface. 1

Measure from the ground to the inside edge of the 2

track at the top central location.

Pull the top of the track upwards and measure the 3

deflection.

The track tension is normal if the deflection is 4

betwen 30 - 40mm.

3

30 - 40mm

2

Loading...

Loading...