TW 230VTR

34 / 65

V-BELT TENSIONING TABLE

C190-0113 01.07.2019 Rev: 4.0

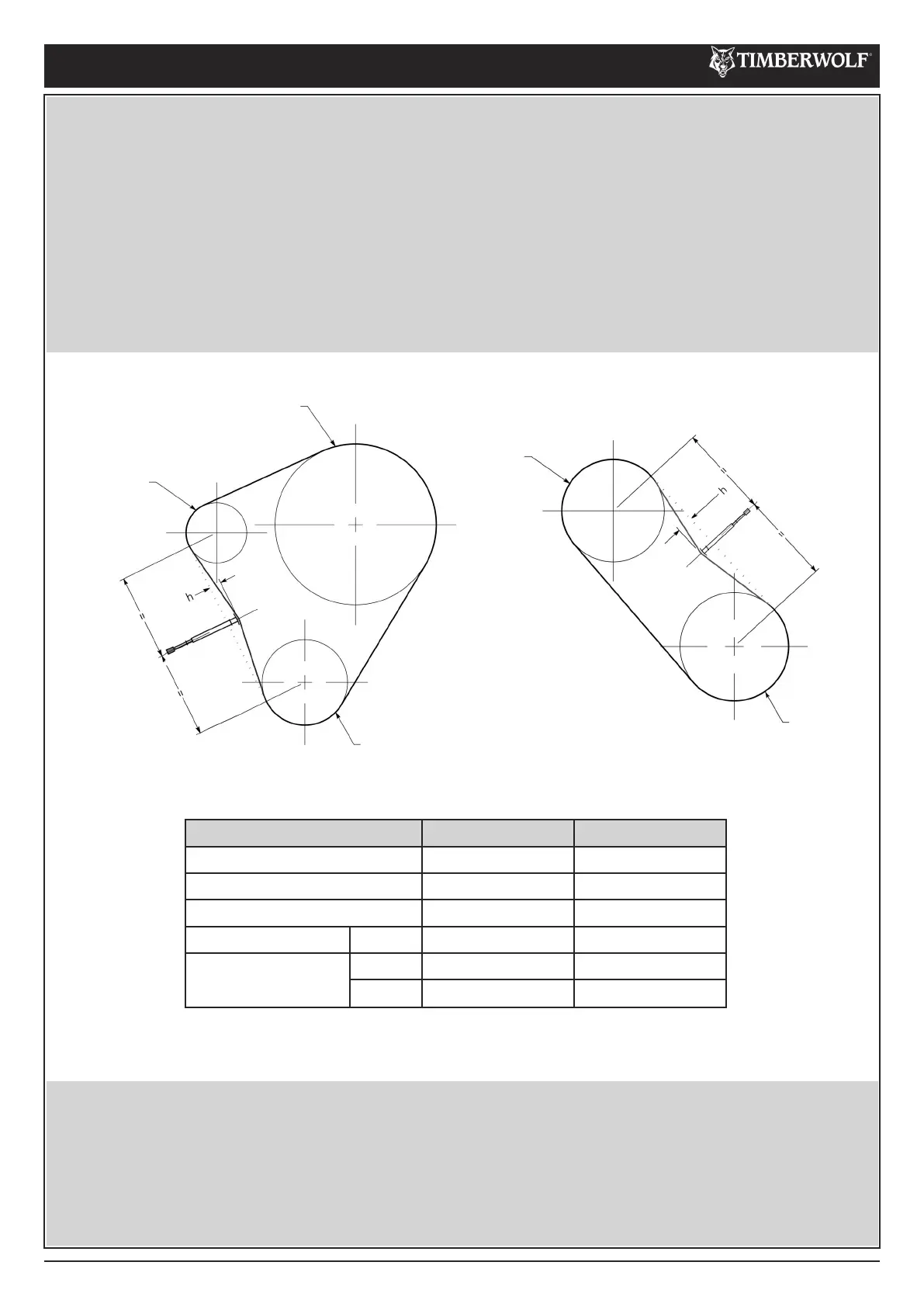

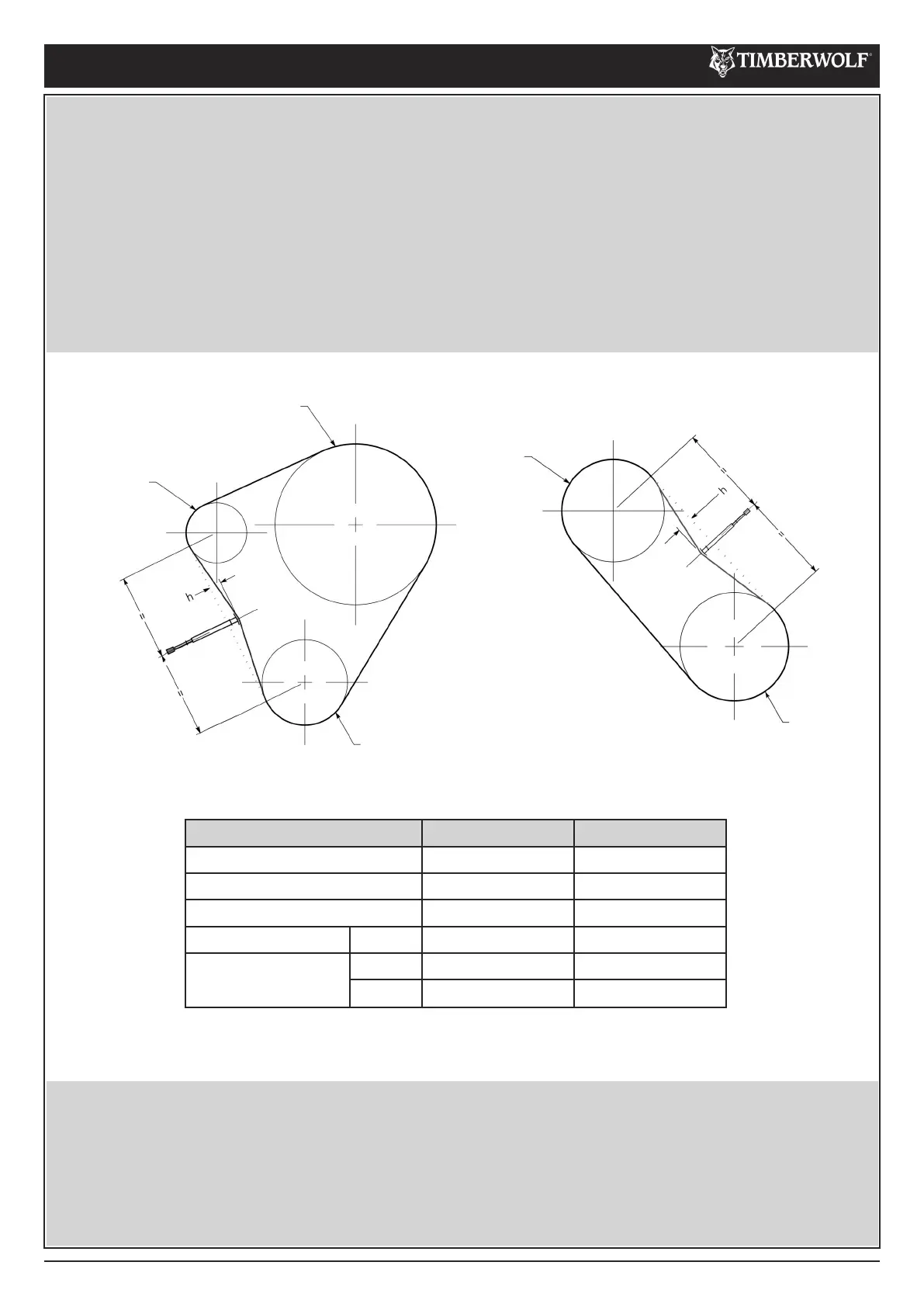

Method:

Set the deflection distance on the lower scale of the tension gauge so that the underside of the 'o'-ring equals the 1

'h' value given in the table.

Ensure that the deflection force scale is zero'd by pushing the upper 'o'-ring all the way down. 2

Place the tension gauge in the centre of the belt span as shown in the diagram. 3

Press downwards on the rubber buffer, deflecting the belt until the underside of the lower 'o'-ring is level with the 4

belt behind (use a straight edge if there is only 1 belt).

Take the reading from the deflection scale of the tension meter (read at the lower edge of the 'o'-ring) & 5

compare this value with that given in the table.

Tighten or loosen belts as required following procedure given in this operator's manual. 6

Tension gauges are available from Timberwolf spares, quoting part no. 18091

Rotor

Pulley

Engine Pulley

Belt

Tensioner

Engine

Pulley

Pump

Pulley

ROTOR BELTS

PUMP BELTS

Tips on belt tightening:

There will normally be a rapid drop in tension during •

the run-in period for new belts. When new belts are

fitted, check the tension every 2-3 hours & adjust

until the tension remains constant.

The best tension for V-belt drives is the lowest •

tension at which the belts do not slip or ratchet

under the highest load condition.

Too much tension shortens belt & bearing life. •

Too little tension will affect the performance of your •

machine especially in respect of no-stress devices.

Ensure that belt drives are kept free of any foreign •

materials.

If a belt slips - tighten it! •

TW 230VTR Rotor Belts

Pump Belts

Belt Mffr / Type Gates Super HC-MN Quad Power III

Belt Pitch Designaon SPA XPA

Belt Length in mm 1232 850

Belt Deflecon in mm = h 2.8 2.1

Force Reading (Kg)

New belt 1.9 - 2.1 1.5 - 1.6

Used Belt 1.7 - 1.8 1.3 - 1.4

Loading...

Loading...