25 / 65

SERVICE INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

TW 230VTR

Check that the grease contained in the hydraulic 1

cylinder has been removed.

Mesh the track links in the sprocket and place the other 2

end of the track on the track-stretching wheel.

Locate the track on the stretching wheel using levers if 3

required.

Make sure track links mesh correctly in the sprocket 4

and in the track stretching wheel.

Adjust track tension (see track loosening procedures on 5

page 24).

Set the tracked undercarriage on the ground.6

CHECKING SPROCKET WEAR

Measuring wear on sprocket and driving gear teeth is one

of the most difficult measurements to be done. You must

always consider the point where wear is greatest.

There should always be enough tooth left on the sprocket

to engage fully with the rubber track. When the sprocket

meshing distance is reduced significantly the sprocket

should be changed.

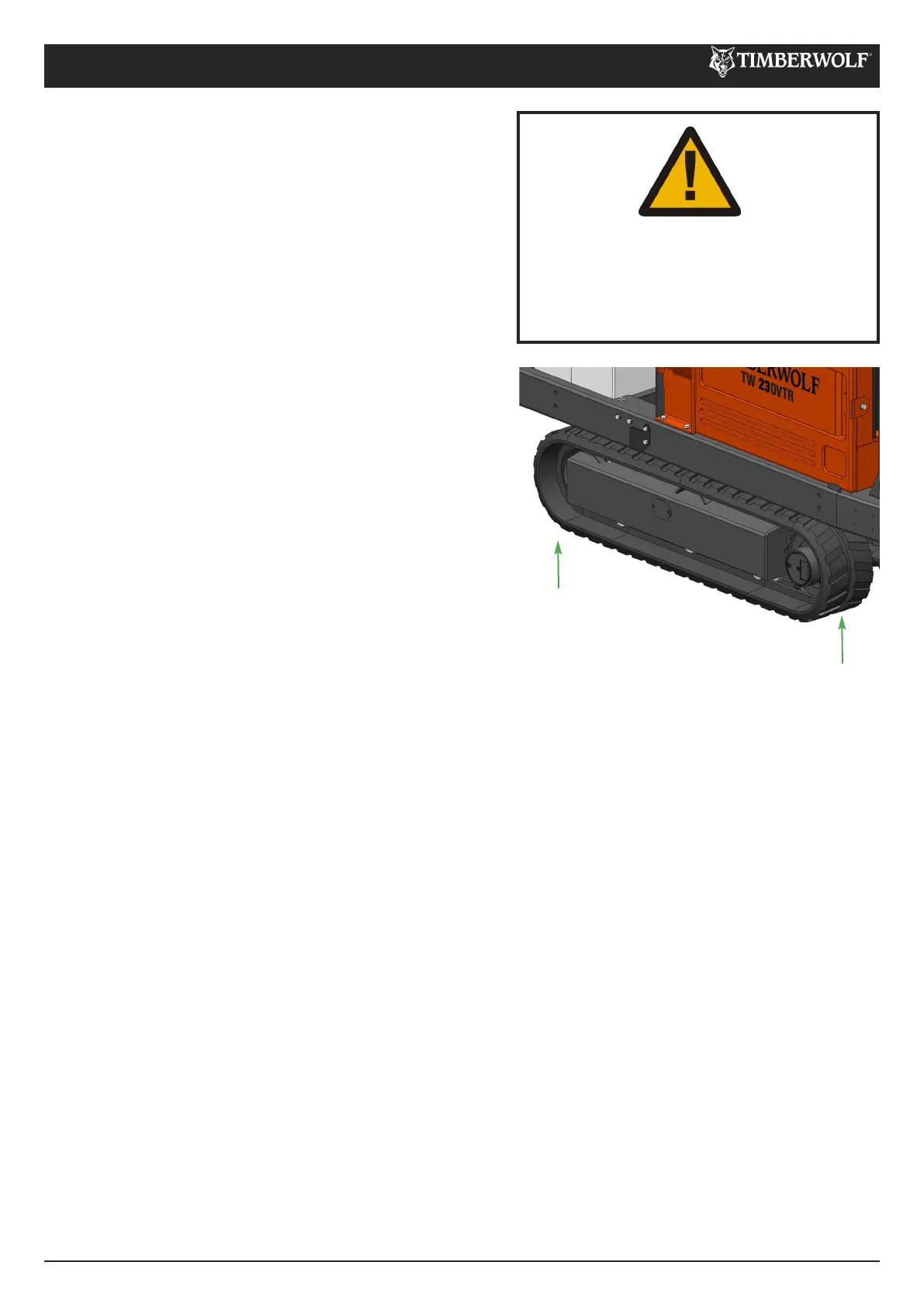

INSTALLING THE RUBBER TRACKS

Stretching wheel end

Drive sprocket end

WARNING

MAKE SURE THAT YOU ARE ALWAYS IN

SAFE CONDITIONS WITH THE MACHINE

LIFTED TO PERFORM THE OPERATION

FOR TRACK INSTALLING.

Loading...

Loading...