22 / 65

SERVICE INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

TW 230VTR

Safe Maintenance

Solidly support the under carriage if it needs to be •

lifted up for maintenance (see Chassis Jacking

Point section on page 20).

Hydraulic systems may get very hot after working. •

Keep all components in good condition as they •

are exposed to high pressures.

Immediately repair damage and replace worn or •

broken items.

Keep the tracks clean, removing excess oil, grease •

and dirt.

Check for oil leaks and damaged hoses. •

Only use recommended lubricants. Do not mix •

different brands.

Keep track stretcher grease nipples clean.•

Maintenance intervals are only guidelines. The amount of times maintenance is conducted should be increased beyond

recommended guidelines if severe conditions are encountered.

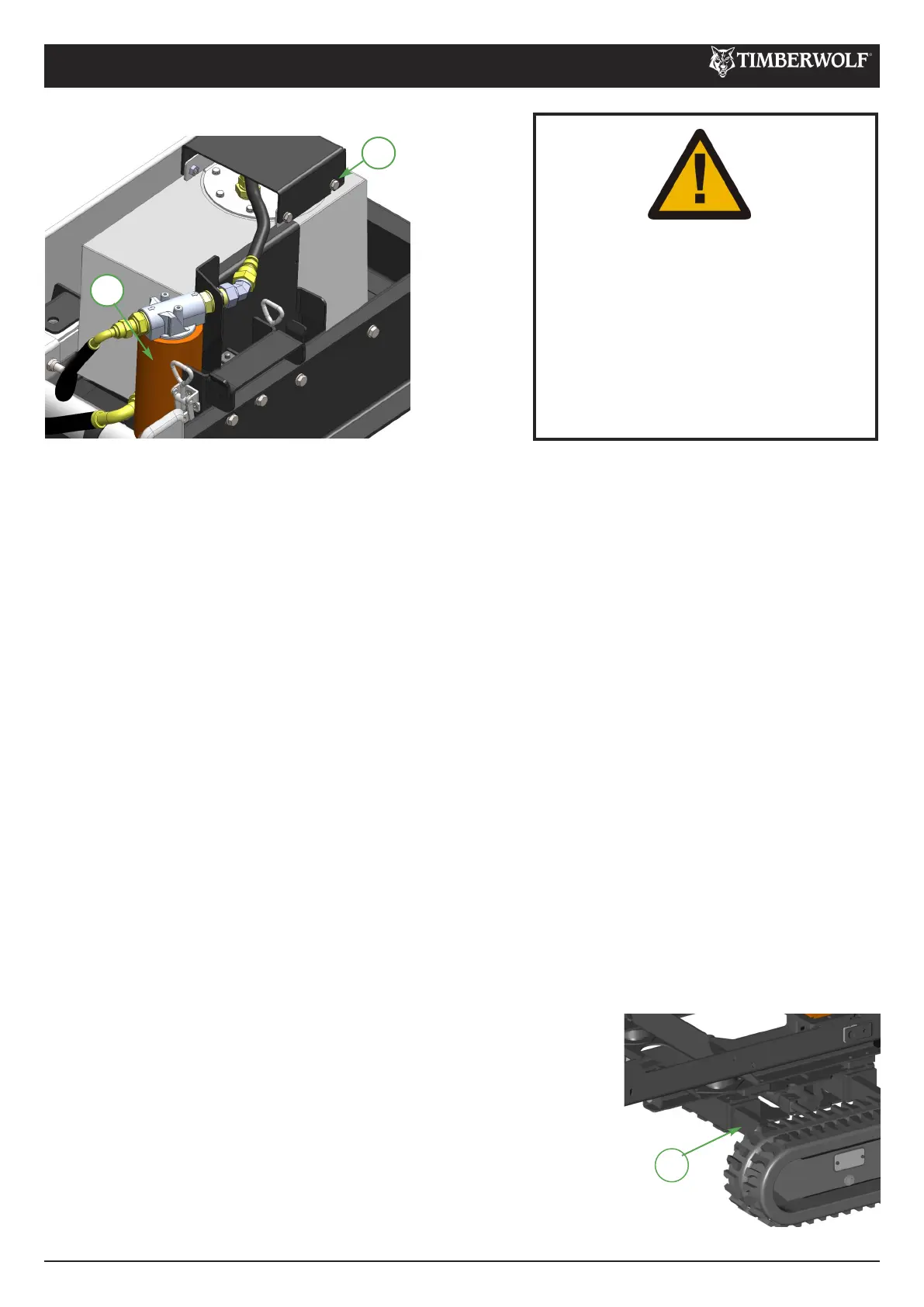

The variable track base slides must be lubricated weekly or more often

depending working conditions to prevent jamming.

Extend tracks fully. 1

Using a brush, generously coat all surfaces of the four slider bars with 2

general purpose grease. DO NOT USE GRAPHITE BASED GREASE.

Retract the tracks fully. 3

Cycle tracks in and out two more times.4

2

LUBRICATE VARIABLE TRACK BASE SLIDES

1

4

TRACK BASE MAINTENANCE

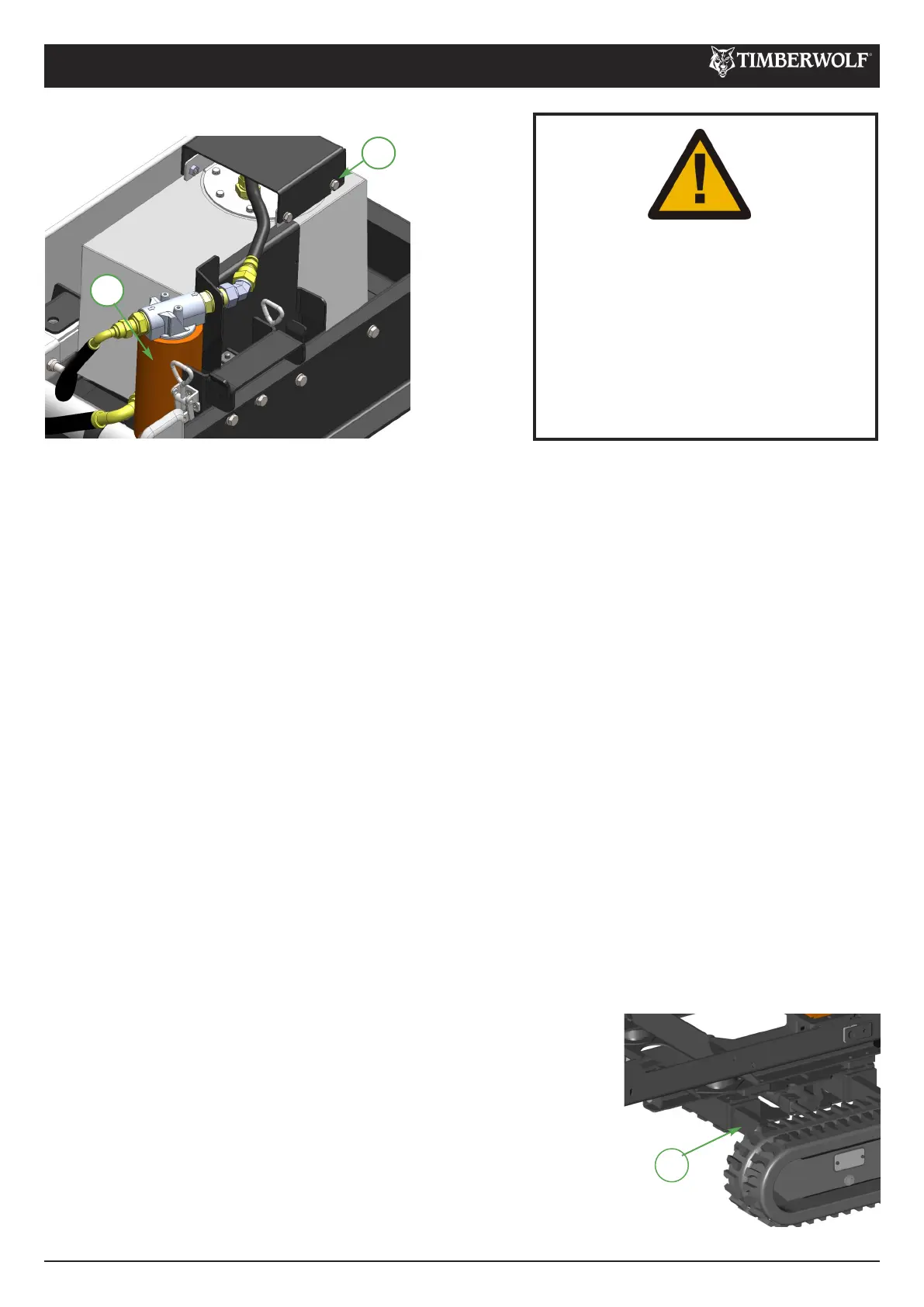

CHANGE HYDRAULIC OIL AND FILTER

WARNING

USE PLASTIC GLOVES TO KEEP OIL OFF

SKIN AND DISPOSE OF THE USED OIL

AND FILTER IN AN ECOLOGICALLY

SOUND WAY. THE OIL AND FILTER

SHOULD BE CHANGED ONCE A YEAR

OR AT ANY TIME IT BECOMES

CONTAMINATED. BEFORE STARTING

CHECK THAT THE CHIPPER IS STANDING

LEVEL AND BRUSH AWAY LOOSE CHIPS.

NOTE: This is a non-adjustable air breather filter.

Locate the oil filter cartridge and unscrew (a filter 1

strap or similar tool may be required to loosen the

filter).

Apply a smear of oil onto the seal of the new filter. 2

Screw new filter on. Hand tighten only. 3

Loosen the four M8 bolts and remove the hydraulic 4

tank cover.

Remove filler cap from tank. 5

Remove drain plug from the hydraulic oil tank and 6

drain oil into a suitable container.

Replace drain plug. 7

Refill with VG 32 hydraulic oil until the level is 8

between the min and max lines on the tank (about 15

litres).

Refit filler cap and hydraulic tank cover.9

Loading...

Loading...