TW 230VTR

20 / 65

SERVICE INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

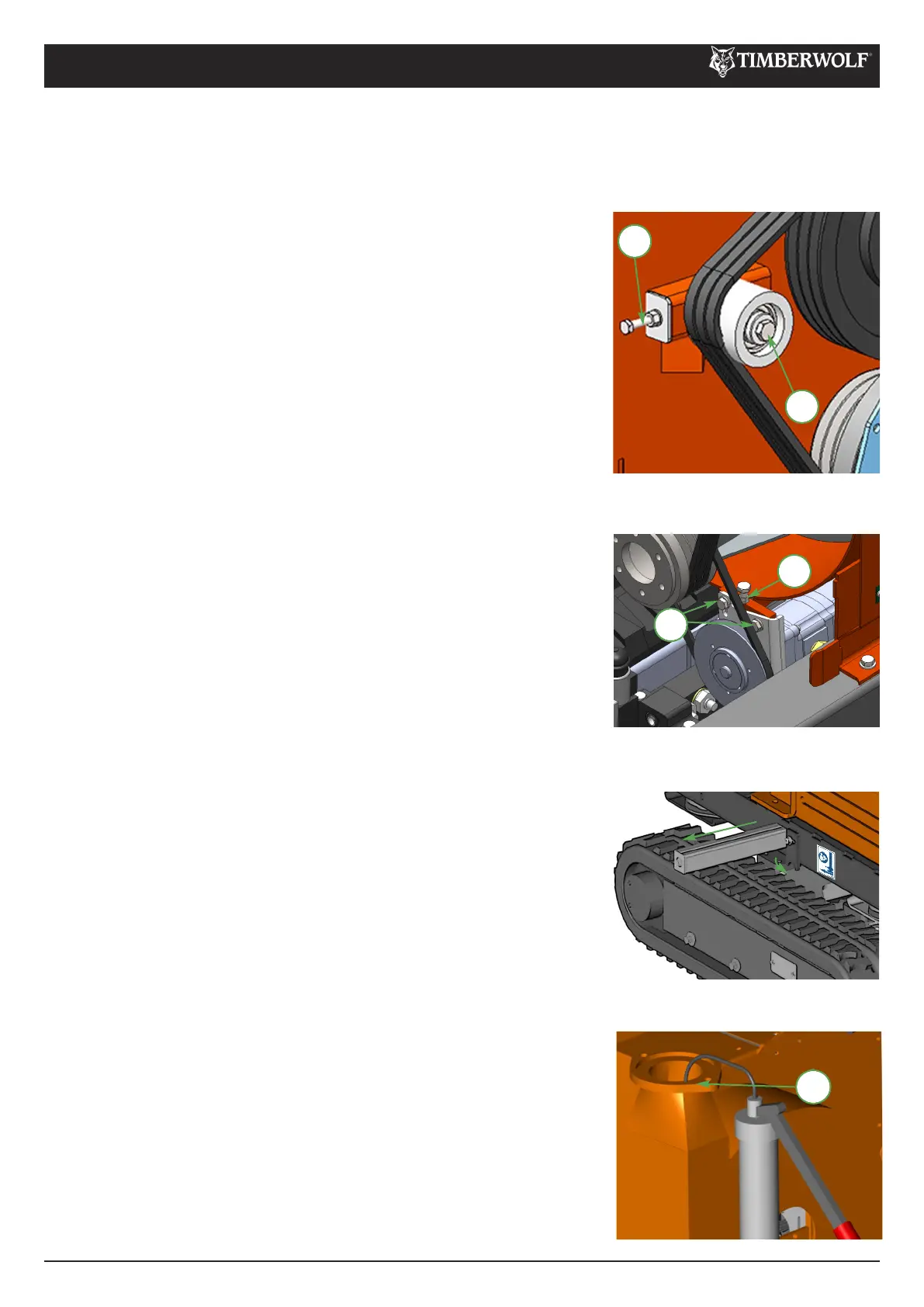

TENSION DRIVE BELTS

Remove engine bay side panel. 1

Loosen bolt in centre of tensioner pulley with a 19 mm 2

spanner so that pulley is able to slide with minimal wobble.

Turn nut in end of tensioner pulley slider until correct belt 3

tension is achieved. For instructions on checking belt

tension & correct belt tension values, please refer to the

Timberwolf V-Belt Tensioning Data Table (page 34).

Re-tighten bolt in centre of tensioner pulley. 4

Run machine and test, recheck belt tension. 5

NOTE: Slack drive belts will cause poor performance and excess

belt and pulley wear.

NOTE: There will normally be a rapid drop in tension during run-in period for new belts. When new belts are fitted,

check the tension every 2 - 3 hours and adjust until the tension remains constant. Belt failures due to lack of correct

tensioning will not be covered under your Timberwolf warranty.

Remove the discharge tube. 1

Apply multipurpose grease to surface shown. 2

Refit discharge tube.3

GREASE THE DISCHARGE FLANGE

3

2

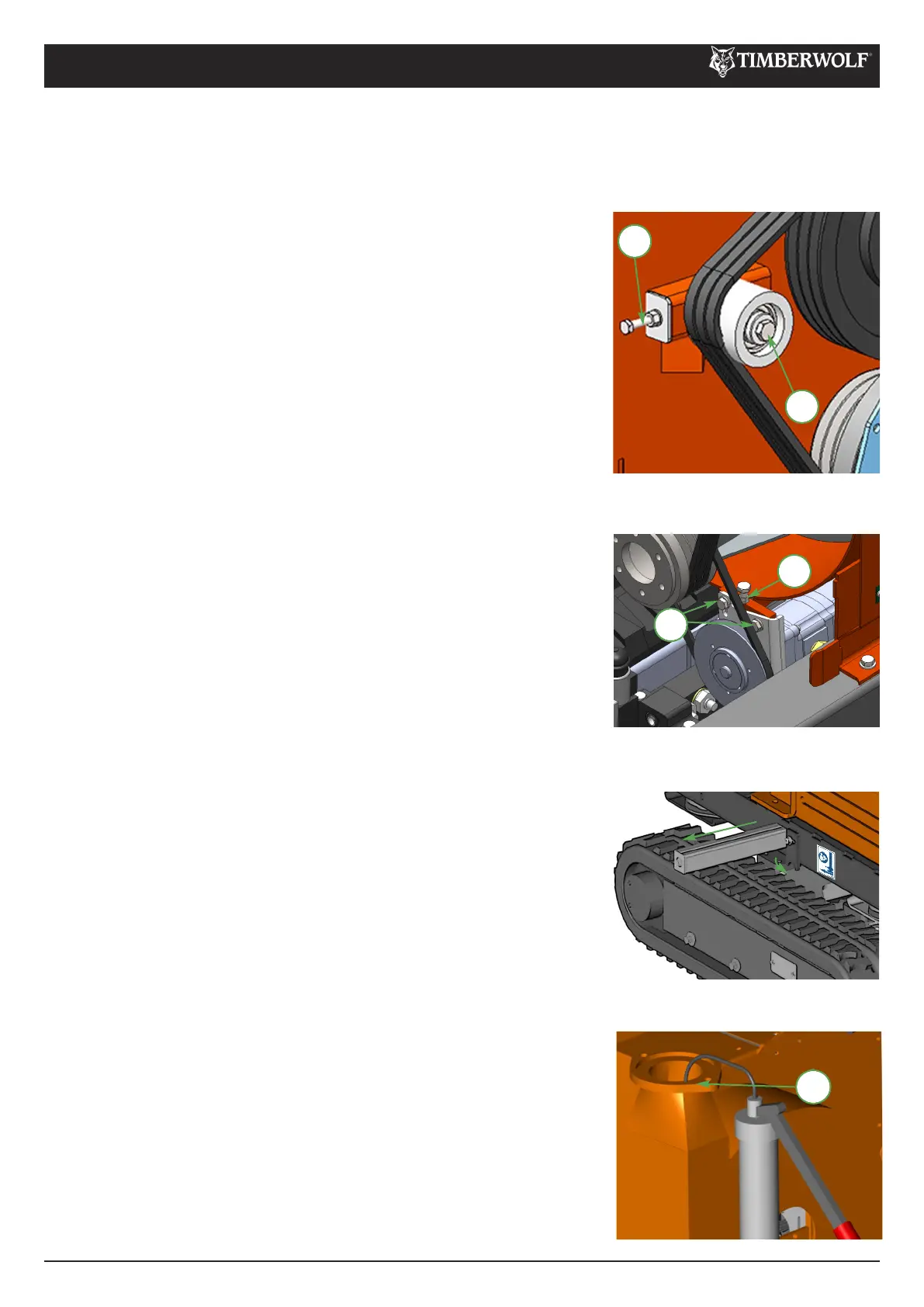

TENSION HYDRAULIC PUMP BELT

Loosen the cover plate bolt on the appropriate side of the chipper. 1

Rotate cover plate, allowing it to remain attached to the chassis. 2

Pull the jacking beam from the access hole to its fullest extent (approx 3

300 mm).

After use, push beam back into access hole and secure cover plate.4

Loosen the 2 M10 bolts on the mounting pad. 1

Loosen the M8 lock nut. 2

Adjust M8 bolt to tension/slacken drive belt. For instructions on 3

checking belt tension & correct belt tension values, please refer to the

Timberwolf V-Belt Tensioning Data Table (page 34).

Re-tighten lock nut and M10 bolts.4

2

1

2

CHASSIS JACKING POINT

Loading...

Loading...