24 / 65

SERVICE INSTRUCTIONS

C190-0113 01.07.2019 Rev: 4.0

TW 230VTR

REMOVING THE RUBBER TRACKS

Remove gravel or mud when they are jammed between the

sprocket and the track link before loosening the track.

Stop your machine on a solid and level surface. Lift it up and 1

support it in safe conditions.

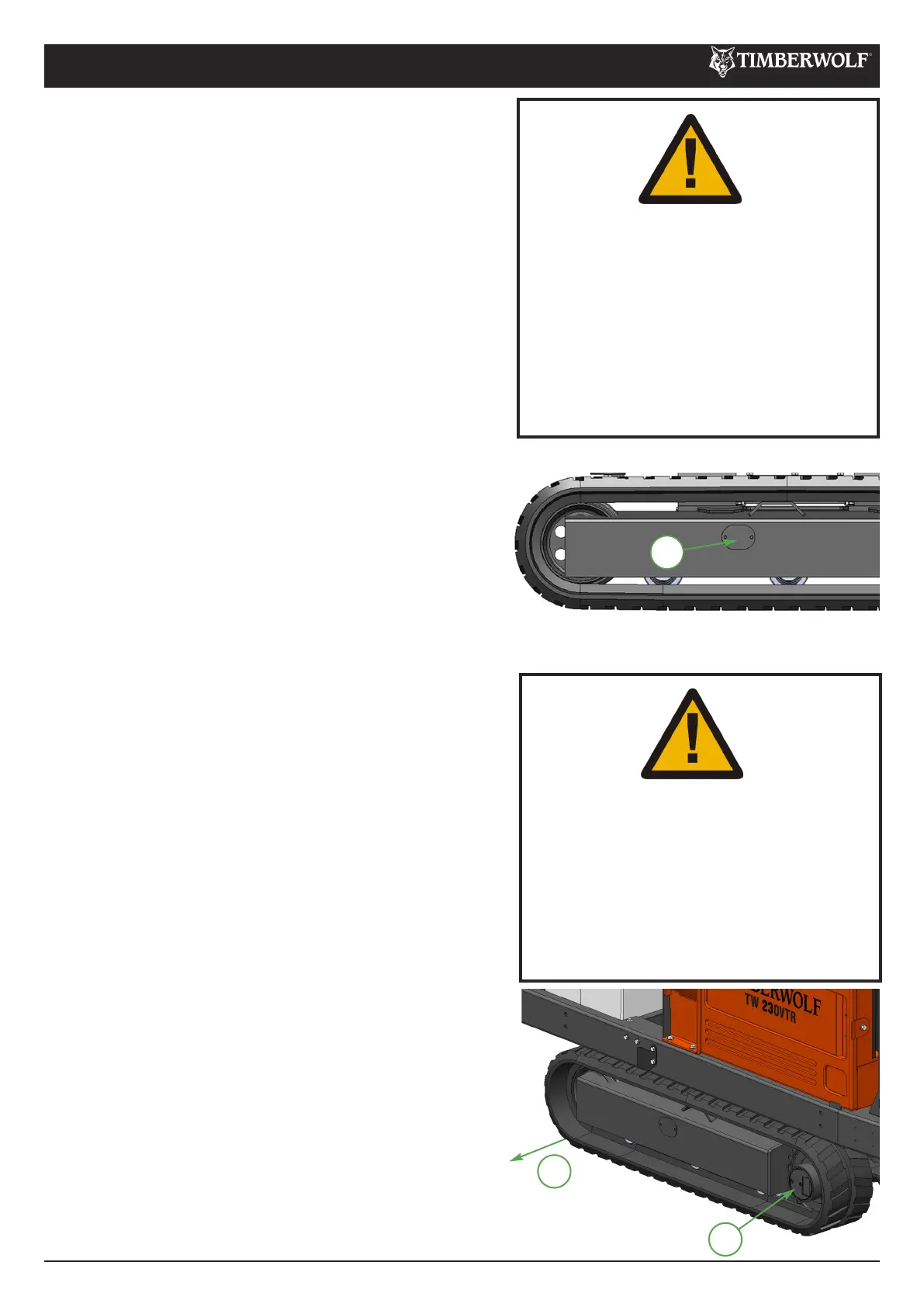

Locate grease nipple under coverplate in side frame to 2

access to the adjustment system (No. 1, Fig. 1).

To loosen a track turn the grease nipple counter-clockwise 3

slowly then the grease should begin to be expelled after

approximately 2 turns.

If grease does not start to drain out then slowly rotate the 4

track forward and reverse to free adjuster mechanism.

Using levers exercise force sideways to slide the track off the 5

track-stretching wheel.

Remove track from drive sprocket end.6

5

Fig. 1

TRACK LOOSENING/TIGHTENING PROCEDURES

Track tension is maintained by grease in the adjuster unit.

Adding more grease will increase track tension, removing grease

will decrease it.

The grease contained in the hydraulic track tensioner ram is

pressurised. Never release grease nipple (No. 1, Fig. 1) for more

than necessary to slowly release grease to a maximum of five

turns. If the valve is loosened too much you risk expelling grease

under pressure and possible injury to the machine operator.

Remove gravel or mud when they are jammed between the

sprocket and the track link before loosening the track.

Locate grease nipple under coverplate in side frame (Fig. 1) 1

to access the adjustment system.

To loosen the track turn the grease nipple counter-clockwise 2

slowly, the grease should begin to be expelled after

approximately two turns.

If grease does not start to drain out then slowly rotate the 3

track forward and reverse to free adjuster mechanism -

grease may then be expelled under pressure as track tension

is relieved.

When you have obtained correct track tension then turn 4

valve clockwise and tighten it. Clean all traces of extruded

grease.

To stretch the track connect a grease gun to grease nipple 5

and add grease until track tension falls within specified

values.

6

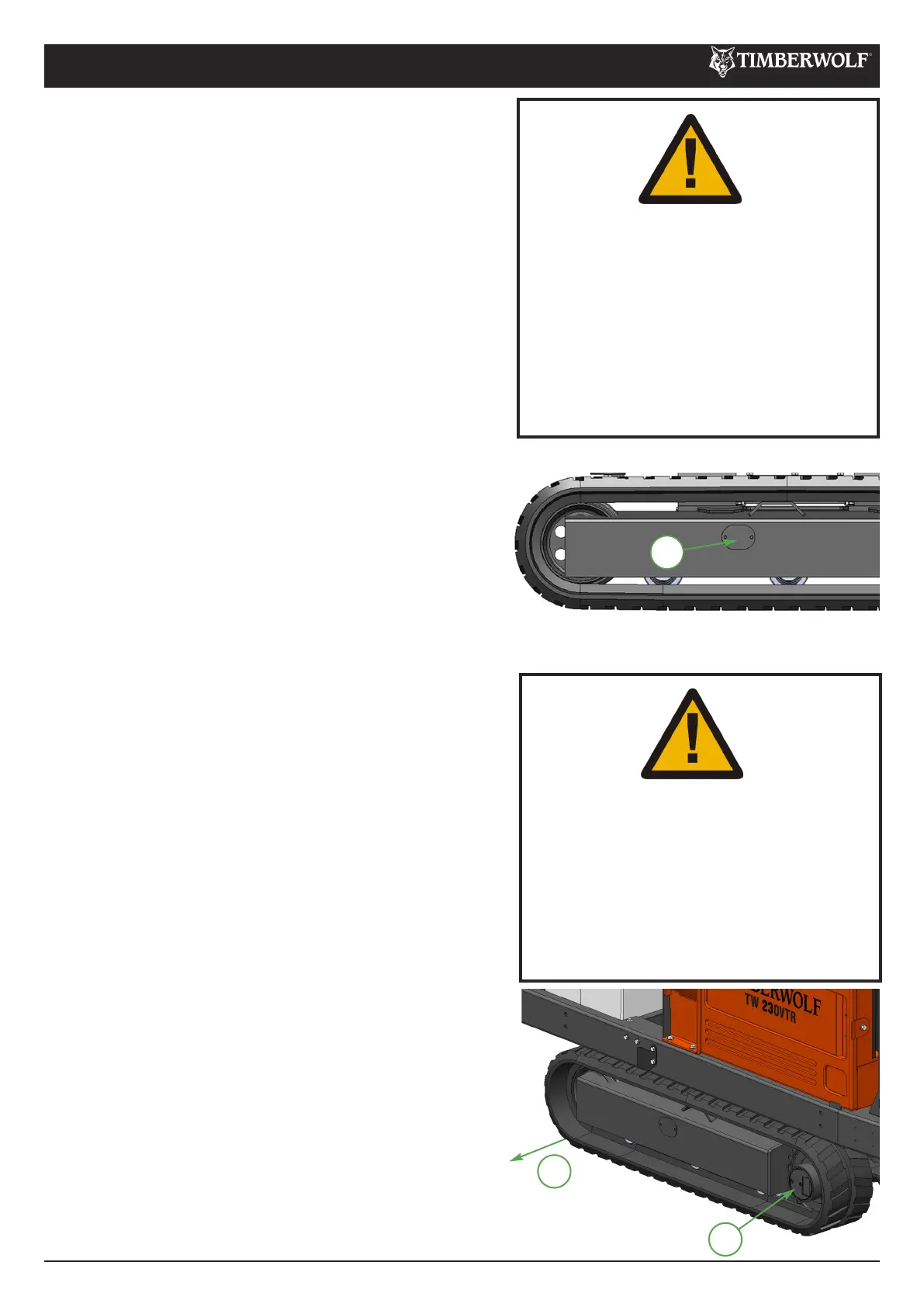

WARNING

IT IS NOT NORMAL FOR THE TRACK TO

REMAIN TOO TIGHT AFTER TURNING THE

GREASE NIPPLE COUNTERCLOCKWISE

OR FOR IT TO REMAIN LOOSE AFTER

INTRODUCING GREASE INTO THE GREASE

NIPPLE. NEVER TRY TO REMOVE THE

TRACKS OR DISASSEMBLE THE TRACK

STRETCHING CYLINDER SINCE PRESSURE

OF THE GREASE INSIDE THE TRACK IS

DANGEROUS.

WARNING

THE GREASE CONTAINED IN THE

HYDRAULIC TENSIONER IS UNDER

PRESSURE. NEVER LOOSEN THE GREASE

NIPPLE FOR MORE THAN 5 TURNS. IF

THE GREASE NIPPLE IS LOOSENED TOO

MUCH THEN PRESSURISED GREASE MAY

EXIT AND CAUSE INJURY TO THE

MACHINE OPERATOR.

1

Loading...

Loading...