Donaldson Company, Inc. © 1995

45

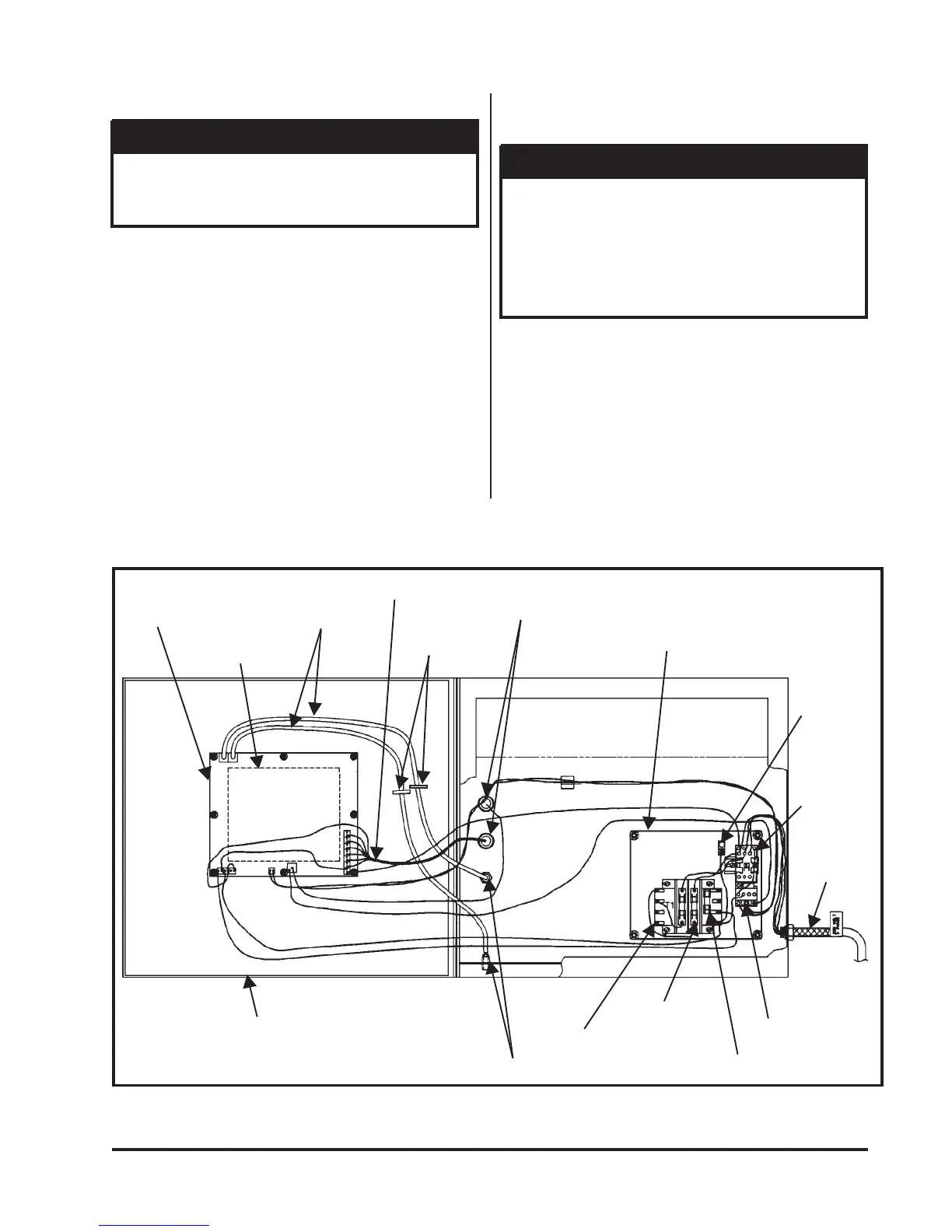

Figure 41

Typical Electrical Component Assembly

Door shown in

an open position

Checker board

PC Assembly

Checker board

Interface

Vinyl Tubing

Conductor Cable

Safety Filters

Mounting Panel

Grounding

Lug

Motor

Starter

(Contactor)

Power Cord

Overload Relay

Transformer

Plastic Bushings

Primary Fuse

Connectors

Secondary Fuse

Shut off and bleed off residual pressure

before performing any service work.

CAUTION

Disconnect the Downflo model SDF from

all electrical power sources and compressed

air supply and bleed off any residual

pressure before performing any service

work.

CAUTION

6.5 Compressed Air Components

1. Periodically check any compressed air filter/

dryer components and service them by

installing new compressed air filters and

draining any moisture off by following

manufacturer's instructions.

2. Check the Downsized Downflo compressed

air manifold for contamination, oil and/or

water. Clean or drain if necessary.

3. With the compressed air supply turned on,

check the cleaning valves, solenoid valves,

and tubing for any leakage. Replace any

components that are leaking compressed air

(reference the Replacement Parts List).

6.6 Electrical Service (See Figure 41 Typical

Electrical Component Assembly)

A model SDF dust collector prewired electrical

compartment equipped with the Checker board

diagnostic and control panel is shown in

Figure 41 Typical Electrical Component

Assembly. For a detailed description of these

parts see the Checker Board Replacement Parts

List RPL-46813-00.

Loading...

Loading...