CAN'T LOAD OR UNLOAD A TOOL, OR THE SPINDLE'S DRAWBAR DRAGS

Can't Load or Unload a Tool, or the Spindle's Drawbar Drags Against the Power Drawbar

Cylinder's Piston Bolt

Cause:Insufficient shop air pressure.

Probability How-To Steps

High Examine the shop air pressure, and verify that there's a minimum of 90 psi

compressed air at the machine's FRLFilter-Regulator-Lubricator.

Cause: Insufficient or excessive preload of drawbar springs.

Probability How-To Steps

Medium Verify that there's sufficient preload of the drawbar disc springs:

1. Examine the shop air pressure, and verify that there's a minimum of 90 psi

compressed air at the machine's FRLFilter-Regulator-Lubricator.

If the machine's inlet air pressure is too low, it limits the machine's ability to

unclamp tools.

2. If the spring stack drags against the power drawbar cylinder bolt, tighten the

spring stack compression nut and jam nut to increase the tool's clamping force.

If you cant' load or unload the tool, loosen the spring stack compression nut and

jam nut to increase clamping mechanism travel.

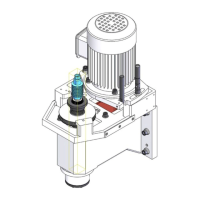

3. (Serial numbers ME10048/MF10028 and earlier, three-stack power drawbar

only) Adjust the power drawbar cylinder's piston bolt to maintain a 0.5 mm

(0.20 in.) gap with the spindle's spring stack when there's no tool loaded in the

spindle. Secure the piston bolt jam nut.

4. Verify that the clamping force is increased as high as possible while still

smoothly and reliably clamping and unclamping tool holders. Repeat Steps 2-3

as necessary.

Cause:Power drawbar cylinder piston is out of adjustment range. (For three-stack power drawbar cylinders

only.)

Probability How-To Steps

Low 1. Loosen the power drawbar cylinder's jam nut and adjust the piston bolt. Verify

that the piston bolt sits within 0.5 mm (0.020 in.)of the spindle's spring stack

when there's no tool loaded in the spindle.

2. Secure the jam nut.

Page 44

©Tormach® 2021

Specifications subject to change without notice.

tormach.com

TD10705: Installation Guide: BT30 Spindle Upgrade Kit for 1100M+ (0521A)

Loading...

Loading...