InstallingtheGearBoxAssembly

RefertoFigure2forthisprocedure.

1.Applymediumstrengththreadlockingcompound(Loctite243orequivalent)

tothethreadsinthereelandallowthethreadlockingcompoundtocurefor

15minutesbeforecontinuingthisprocedure.

2.Insertalong-handledprybarthroughthefrontofthecuttingunit.Thepry

barshouldpassbetweenthetopofthereelshaftandthebacksofthereel

bladessothatthereelwillnotmove.

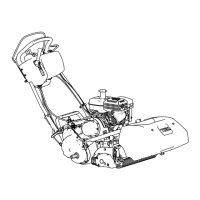

g323290

Figure7

1.5/16–18X5/8inchsquareheadsetscrew4.Reelshaft

2.Inputshaftassembly5.Weldsideofreelsupportplate

3.Groomergearboxassembly

6.Prybar

3.Movetheprybaragainsttheweldsideofthereelsupportplateclosesttothe

gearboxassemblyandrestthehandleoftheprybaragainstthefrontroller.

4.Positionthegearboxassemblyagainstthecuttingunitandturnthedrive

shaftassemblyclockwiseuntilitisseatedagainstthereel.

IMPORTANT

Youmustusea6-pointsocketwithaheavywalltoinstallthegear

boxtothereel.Donotuseanimpactwrench.Groomergearboxes

installedontherightsideofthecuttingunituseastandardright

handthread;turnthedriveshaftclockwisetoinstallthegearbox.

5.Tightenthedriveshaftassemblyfrom135to150N∙m(100to110ft-lb).

6.Removethesquareheadsetscrewfromtheendofthedriveshaft.

7.Installtheclevispinandanewcotterpintosecuretheheightadjustmentrod

tothefrontofthegroomergearbox.

GreensmasterFlex1800/1820/2100/2120

Page9–15

UniversalGroomer(Optional):ServiceandRepairs

12188SLRevD

Loading...

Loading...