SettingUptheDrillHeadandTracking

System

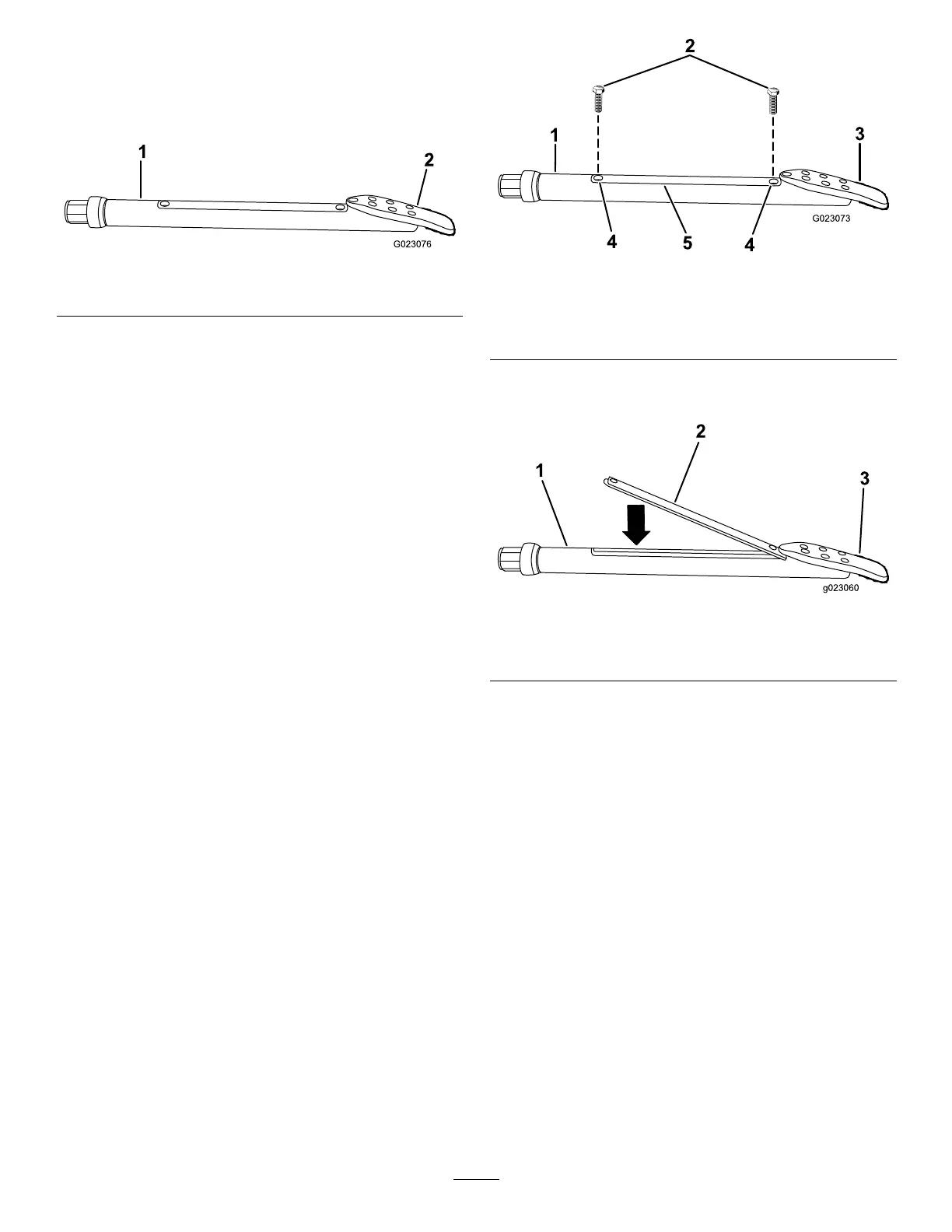

Thedrillheadconsistsoftwoparts,thedrillbitandthesonde

housing(Figure37).

Figure37

1.Sondehousing

2.Drillbit

Drillbitsvaryinsizeandtypetomeetthevarioussoil

conditionsyoumayneedtodrillthrough.Someofthe

possibilitiesareasfollows:

•Straightblade—Usedinawiderangeofmediumdensity

soils.

•Bentblade—Usedinmediumtosoftsoils.Thisbithas

anadded20°bendtoincreasesteeringperformancein

softsoils.

•Trianglepointblade—Useinhardandrockysoils.This

bithascarbideedgestoreducewear.

Alloftheabovebitscomeinvaryingwidths.Awiderblade

increasesyourabilitytosteerinsoftsoils.Anarrowerblade

movesthroughhardsoilsbetter.ContactyourAuthorized

ToroDealerforacompletelistofavailableblades.

Thesondesandreceiversareessentialtotracktheposition

ofthedrillheadthroughoutthedrillingoperation.The

sondehousingonthedrillheadopensuptoacceptthesonde

beaconwhichworkswiththereceivertotrackthelocation,

pitch,direction,headorientation,andmoreofthedrillhead.

RefertotheTrackingSystemOperator’sManualforinstructions

onusingthesystem.

Toinstallthesondebeaconintothesondehousingonthe

drillhead,completethefollowing:

1.Replacethebatteriesinthesondebeaconasdescribed

intheTrackingSystemOperator’sManual.

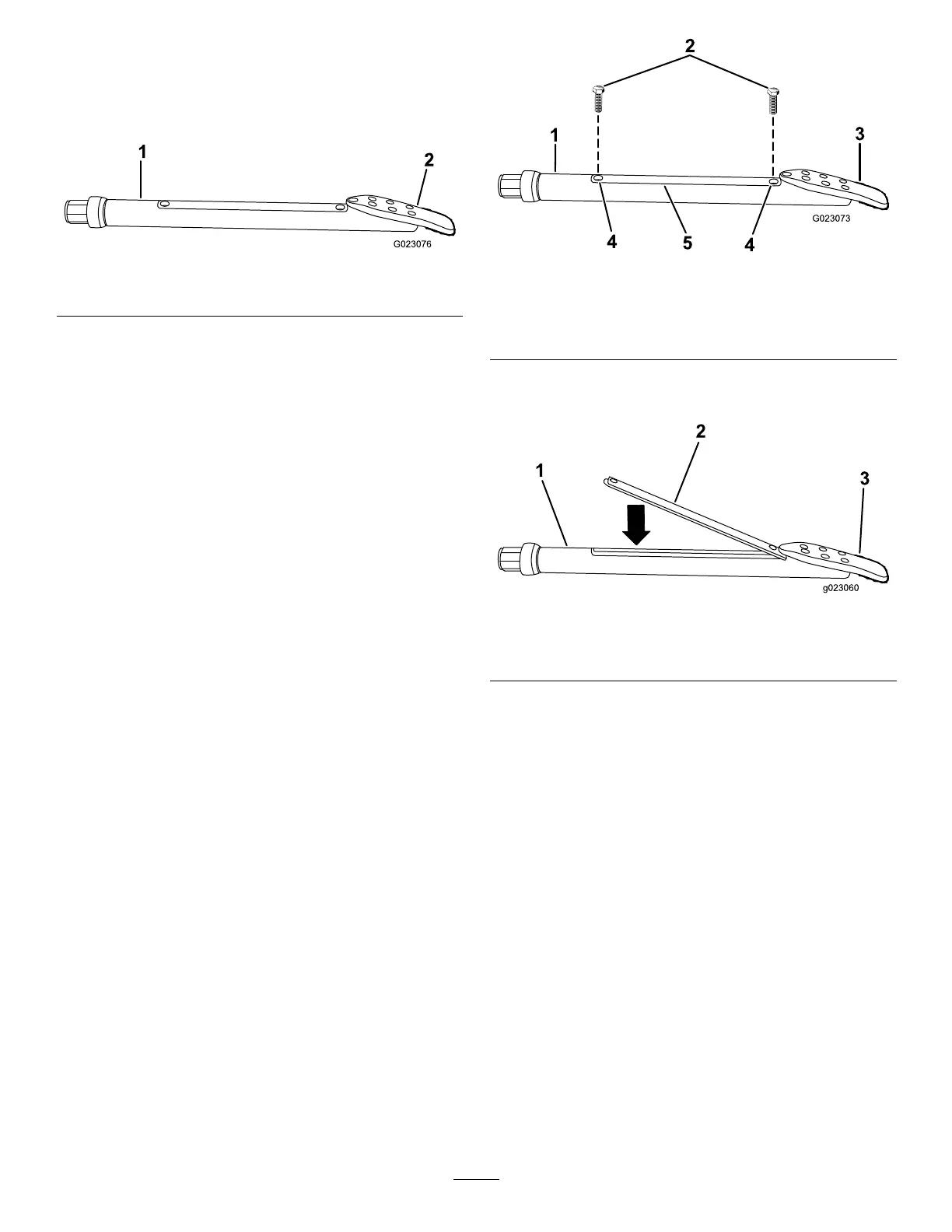

2.Loosenthescrewssecuringthehousingcovertothe

housingandremovethecover(Figure38).

Figure38

1.Sondehousing

4.Housingcover

2.Screws

5.Housing

3.Drillbit

3.Insertthesondebeaconwiththeforwardendtoward

thedrillbitintothesondehousing(Figure39).

Figure39

1.Sondehousing

3.Drillbit

2.Sondebeacon

4.Installthehousingcoverandsecureitwiththescrews

(Figure38).

SettinguptheMachineforDrilling

1.Usingthedrivependant,drivethemachinetothe

locationthatyouhavepreparedforit,ensuringthat

thefrontofthemachineistheproperdistanceback

fromentrypointandthedrillframeisinlinewiththe

borepath.

2.Driveuptothelocationandmakesurethatallutilities

arelocatedandmarkedpriortodrilling.

3.Loosenthe4screwsthatsecurethecoversoverthe

operatorconsolesandremovethecovers(Figure40).

Note:Storethemsomeplacesafefortheday.

45

Loading...

Loading...