Belt Maintenance

Servicing the Alternator Belt

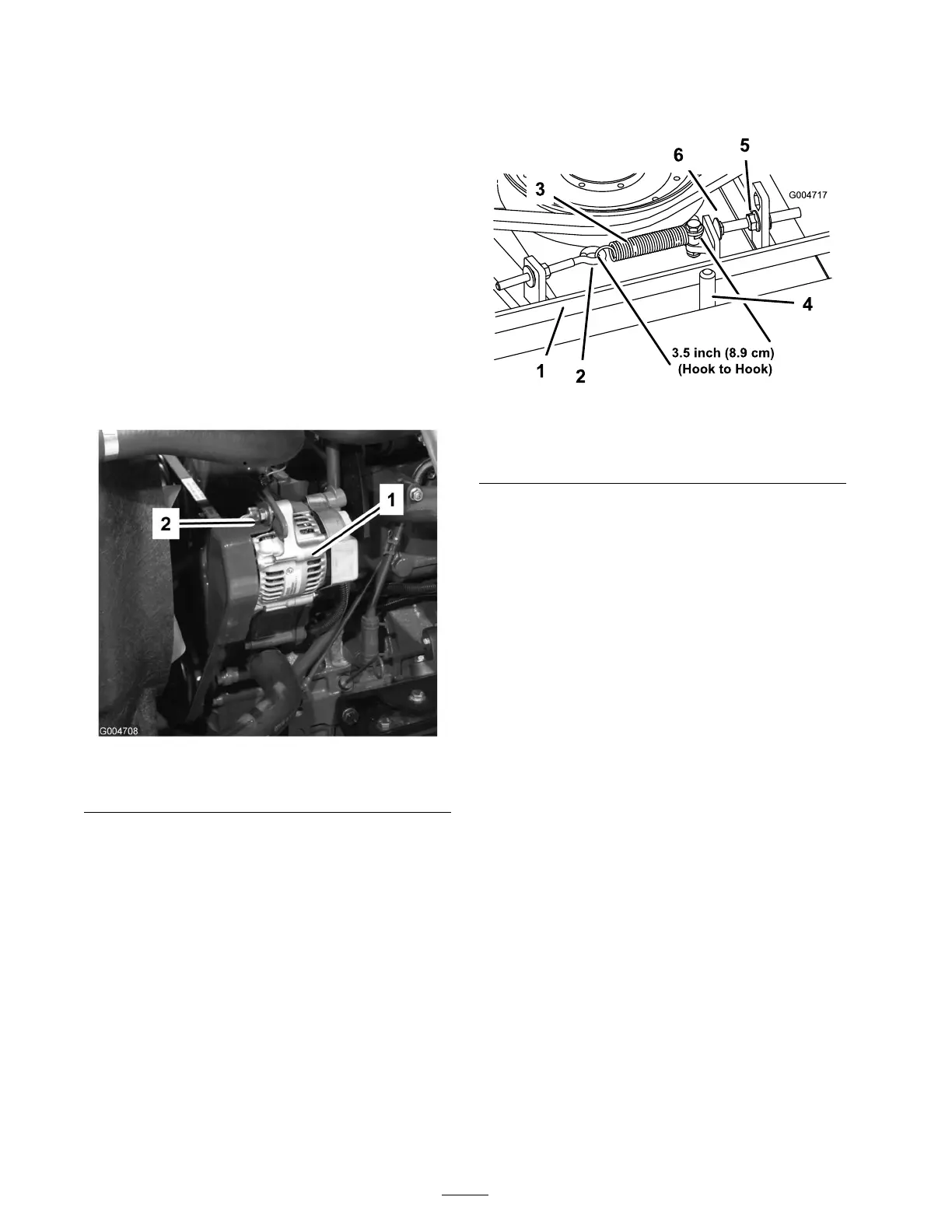

Chec k the condition and tension of the belts

( Figure 63 ) after ev er y 100 operating hours .

1. Proper tension will allo w 3/8 inc h (10 mm)

deflection when a force of 10 lb is applied on

the belt midw a y betw een the pulleys .

2. If the deflection is not 3/8 inc h (10 mm),

loosen the alter nator mounting bolts

( Figure 63 ). Increase or decrease the alter nator

belt tension and tighten the bolts . Chec k the

deflection of the belt ag ain to ensure that the

tension is cor rect.

Figure 63

1. Alternator 2. Mounting bolt

Re-tensioning the Blade

Drive Belts

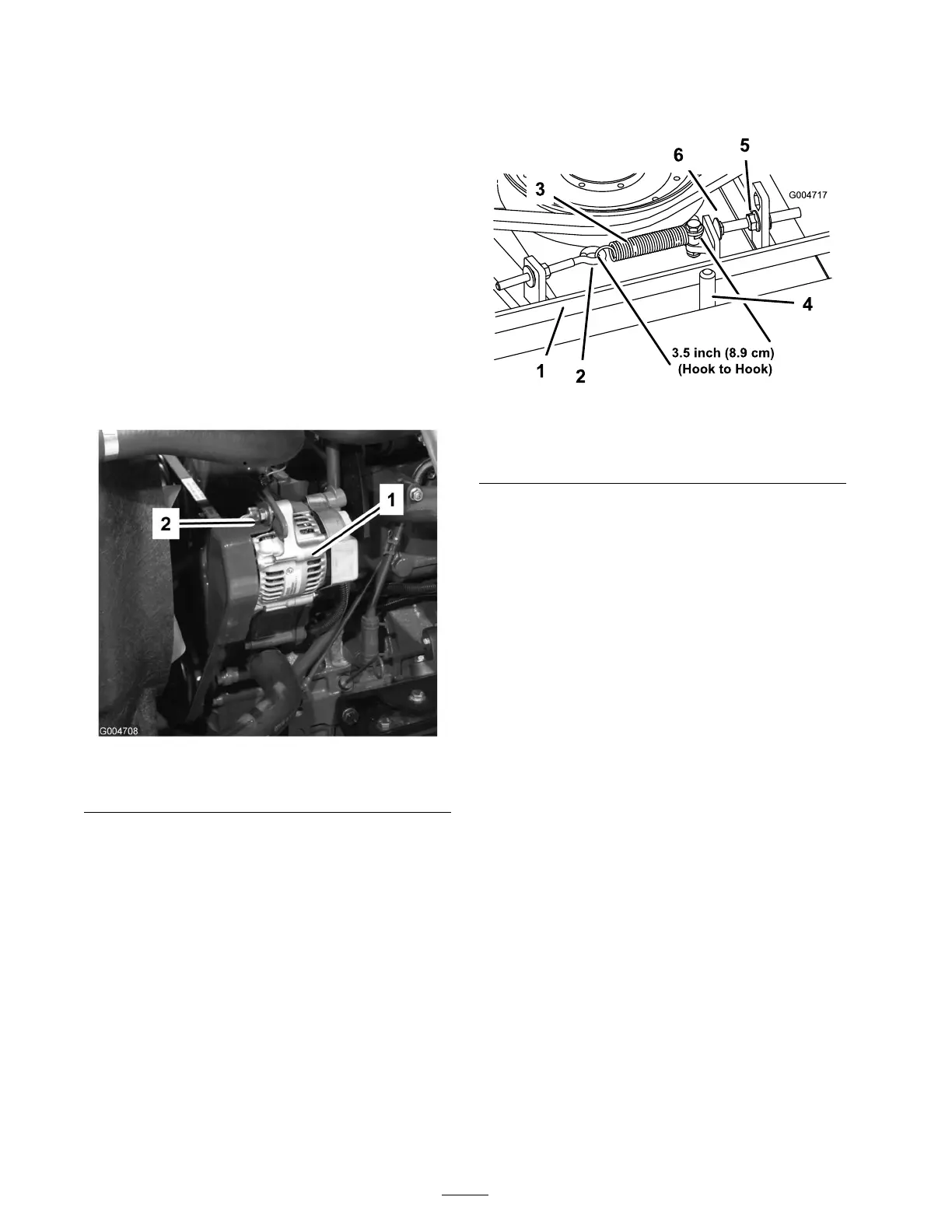

Chec k the condition and tension of the cutting

unit dri v e belts initially after 8 hours of operation

and ev er y 50 operating hours thereafter .

W hen properly tensioned, the extension

spring (hook to hook) measurement should be

appro ximately 3.50 ±.25 inc h (inside). Once the

cor rect spring tension is attained, adjust the stop

bolt (car riag e bolt) until there is appro ximately

.125 +.060/-.000 inc h clearance betw een the head

of the bolt and the idler ar m ( Figure 64 ).

Note: Mak e sure the belt is positioned on the

spring side of the belt guide ( Figure 64 ).

Figure 64

1. Belt 4. Belt guide

2. Eye bolt 5. Flange nut

3. Extension spring

6. Stop bolt

Replacing the Blade Drive

Belt

T he blade dri v e belt, tensioned b y the spring

loaded idler pulley , is v er y durable . Ho w ev er , after

many hours of use , the belt will sho w signs of

w ear . Signs of a w or n belt are: squealing when

belt is rotating, blades slipping when cutting g rass ,

fra yed edg es , bur n marks and crac ks . R e place the

belt if any of these conditions are evident.

1. Lo w er the cutting unit to the shop floor .

R emo v e the belt co v ers from the top of the

cutting unit and set the co v ers aside .

2. Loosen the eye bolt allo wing the remo v al of

the extension spring ( Figure 64 ).

3. Loosen the flang e n ut securing the stop bolt

to the mounting tab . Bac k off the n ut enough

to allo w the idler ar m to pass b y the stop bolt

( Figure 64 ). Mo v e the idler pulley a w a y from

the belt to release belt tension.

Note: If the stop bolt is ev er remo v ed from

the mounting tab , mak e sure it is reinstalled

in the hole that aligns the stop bolt head with

the idler ar m.

4. R emo v e the bolts securing the h y draulic motor

to the cutting unit ( Figure 65 ). Lift the motor

off of the cutting unit and la y it on top of the

cutting unit.

46

Loading...

Loading...