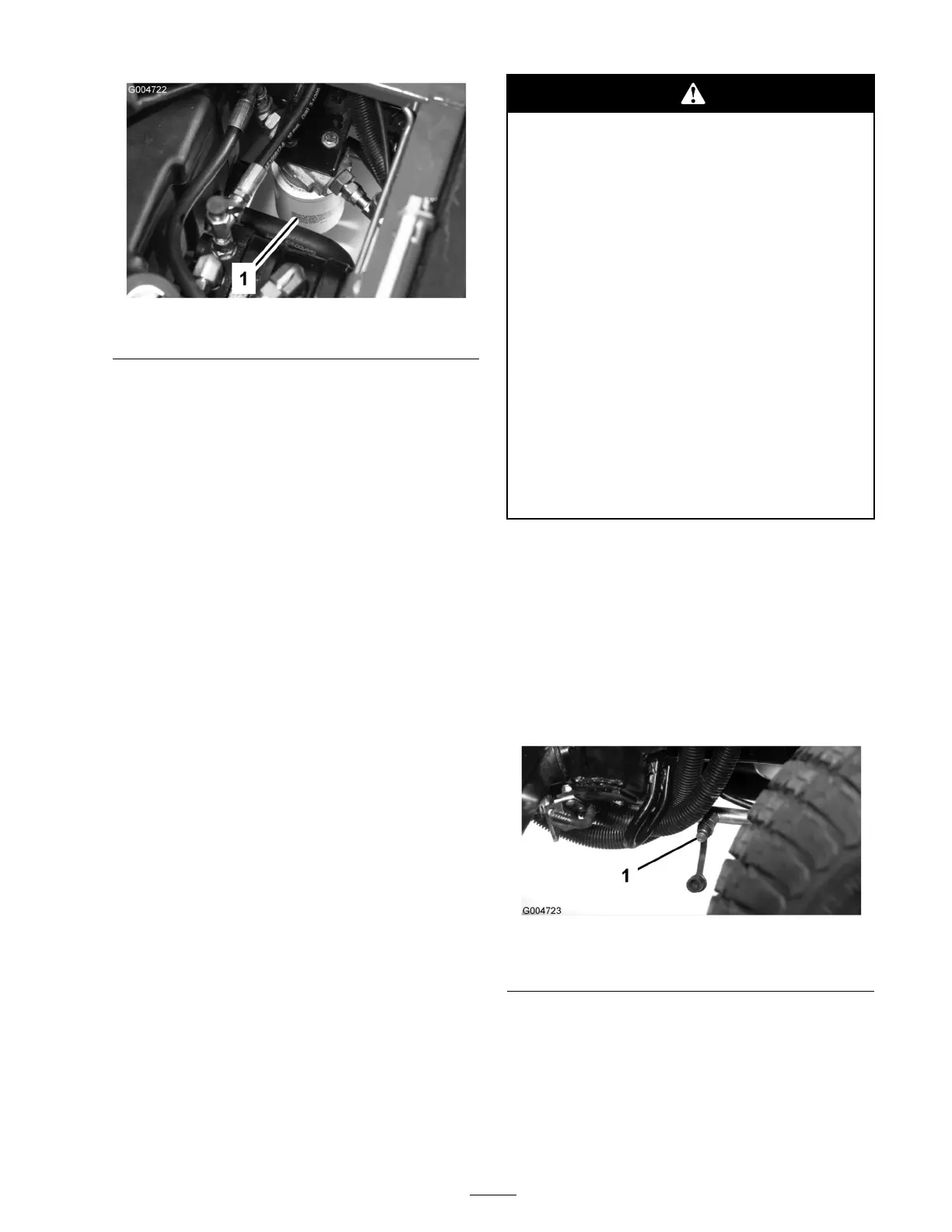

Figure 70

3. Lubricate the new filter g ask et and fill the filter

with h y draulic fluid.

4. Ensure that the filter mounting area is clean.

Screw the filter on until the g ask et contacts

the mounting plate; then tighten the filter an

additional 1/2 tur n.

5. Star t the engine and let it r un for about tw o

min utes to purg e air from the system. Stop the

engine and c hec k for leaks .

Checking the Hydraulic

Lines and Hoses

Inspect the h y draulic lines and hoses daily for

leaks , kink ed lines , loose mounting suppor ts , w ear ,

loose fittings , w eather deterioration, and c hemical

deterioration. Mak e all necessar y re pairs before

operating .

Hy draulic fluid escaping under pr essur e can

penetrate skin and cause injur y .

• Mak e sur e all h y draulic fluid hoses

and lines ar e in good condition and all

h y draulic connections and fittings ar e

tight bef or e appl ying pr essur e to the

h y draulic system.

• K eep y our body and hands a w ay fr om

pin hole leaks or nozzles that eject high

pr essur e h y draulic fluid.

• Use cardboard or paper to find h y draulic

leaks.

• Safel y r eliev e all pr essur e in the h y draulic

system bef or e perf or ming an y w or k on

the h y draulic system.

• Seek immediate medical attention if fluid

is injected into skin.

Hydraulic System Test Ports

T he test por ts are used to test the pressure in

the h y draulic circuits . Contact y our local T oro

distributor for assistance .

T est P or t A ( Figure 71 ), located on the left side

of the mac hine , is used to measure the forw ard

traction pressure .

Figure 71

1. Test port A

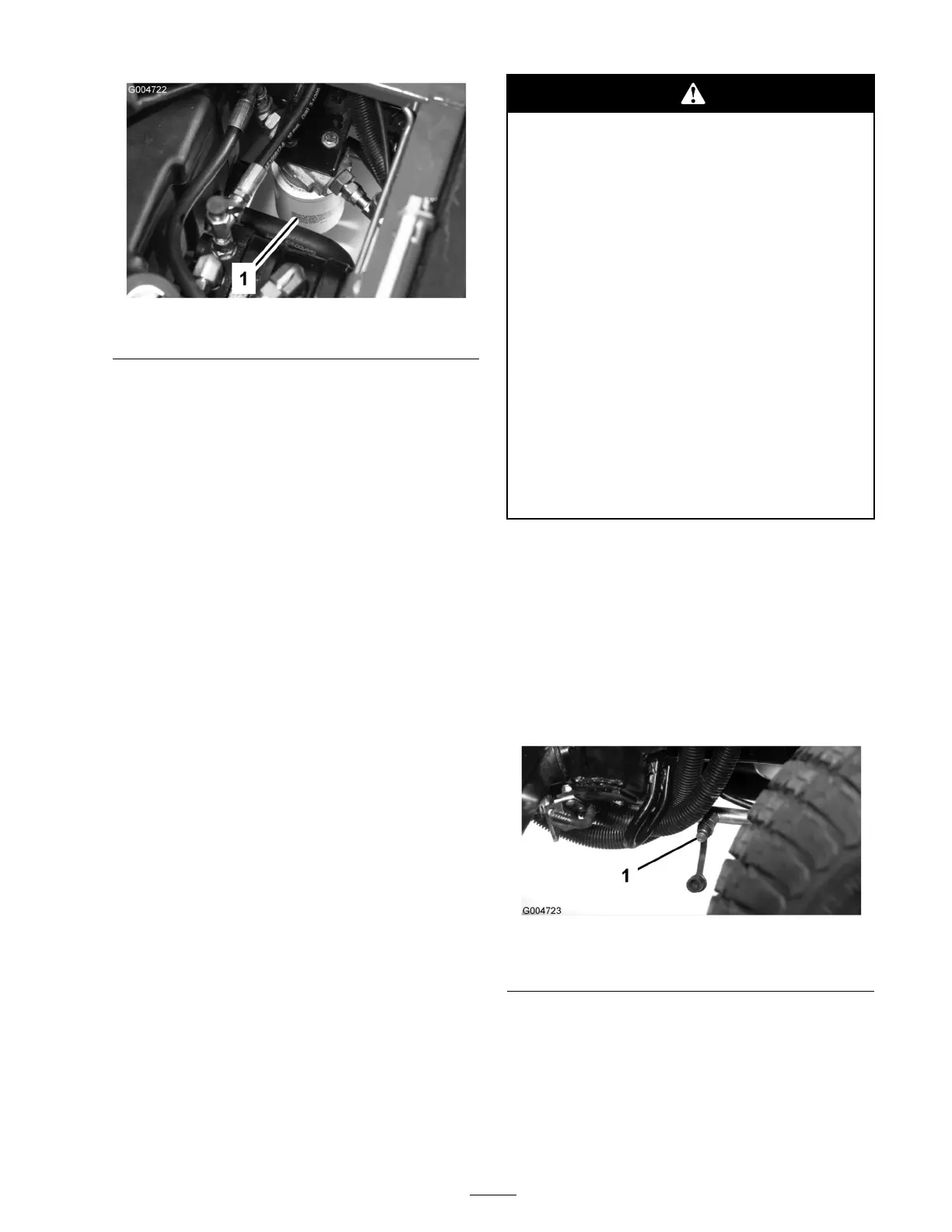

T est P or t B ( Figure 72 ), located on the right side

of the mac hine , is used to measure the rev erse

traction pressure .

49

Loading...

Loading...