If y ou lea v e the k ey in the ignition s witch, someone could accidentl y star t the engine and

seriousl y injur e y ou or other bystander s.

R emo v e the k ey fr om the ignition bef or e y ou do an y maintenance.

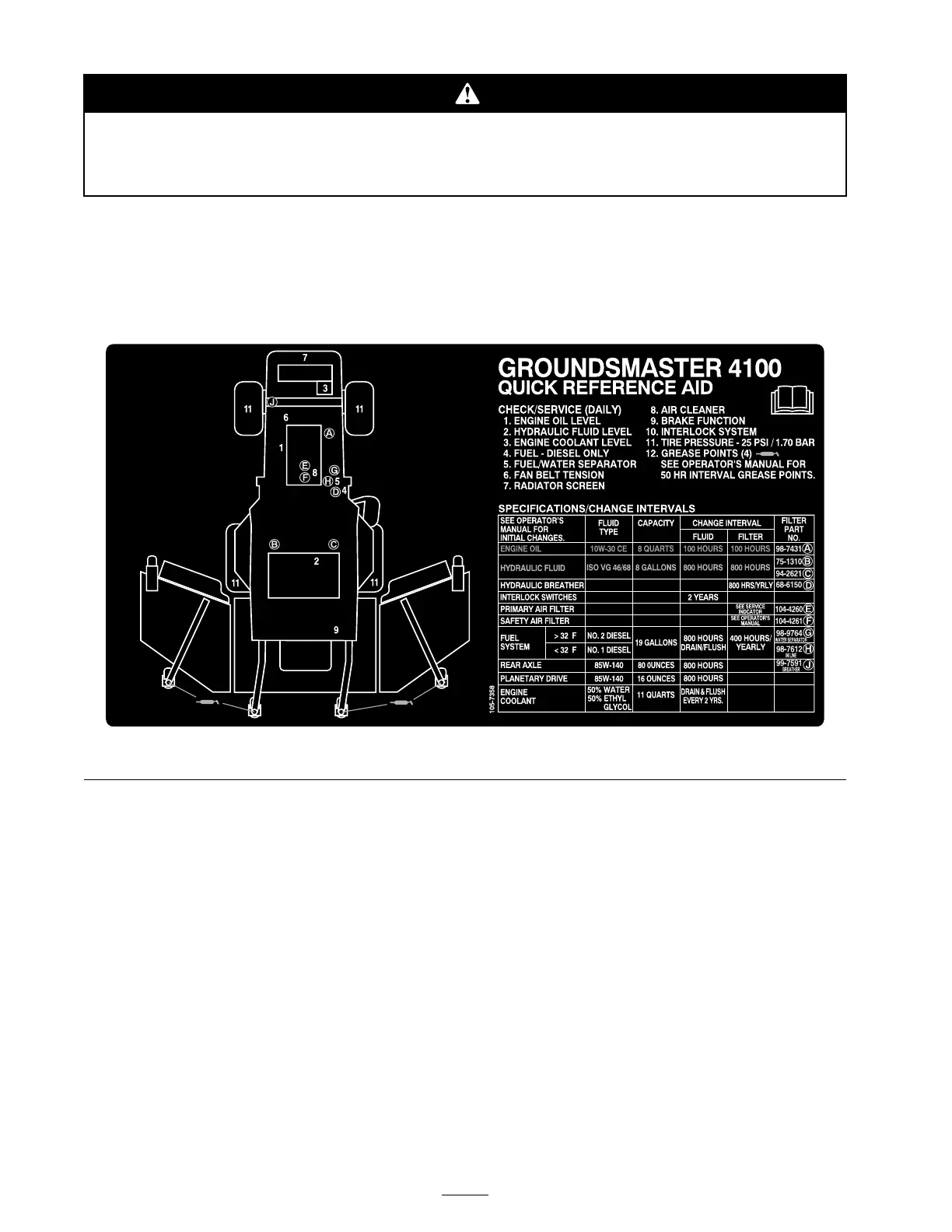

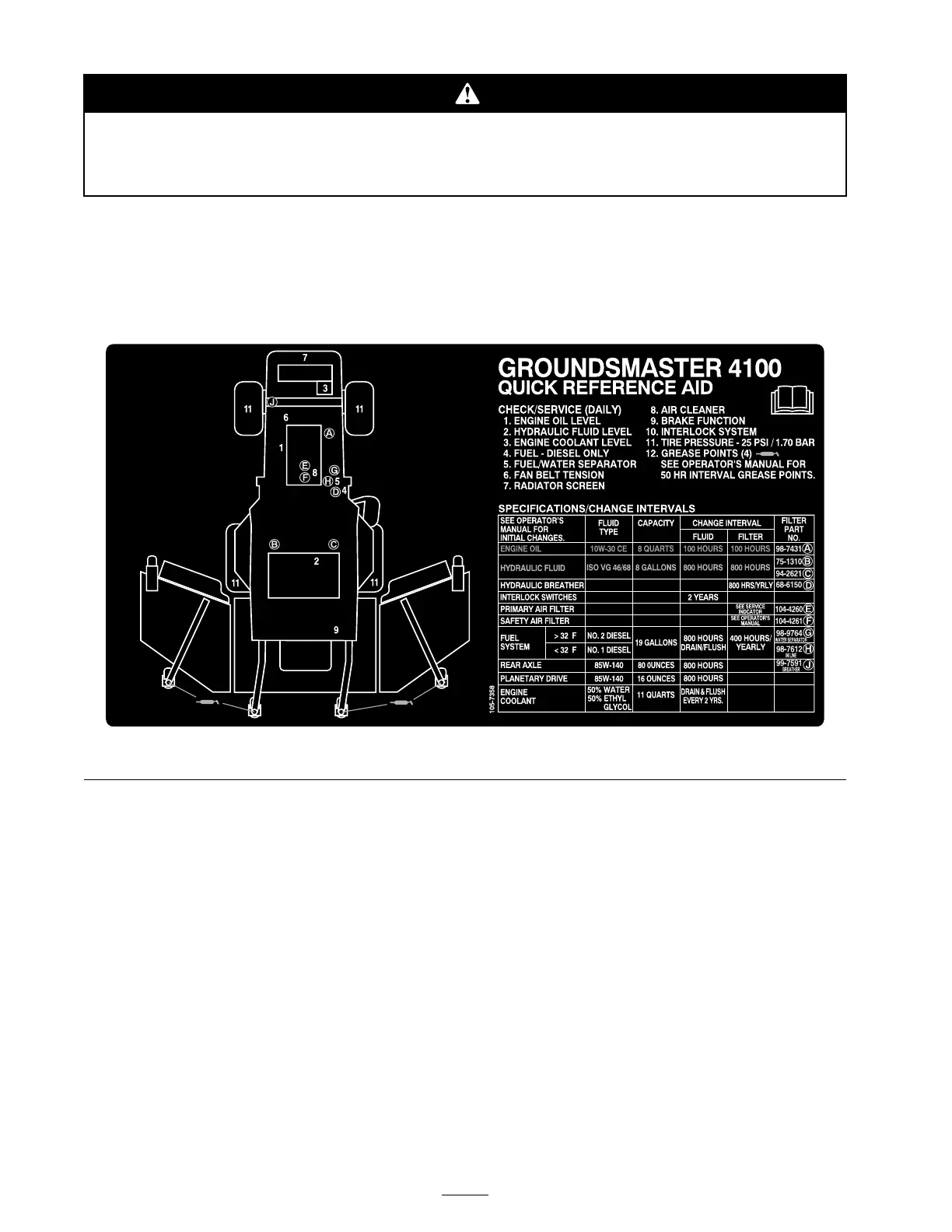

Premaintenance

Procedures

Service Interval Chart

Figure 33

Lubrication

Greasing the Bearings and

Bushings

T he mac hine has g rease fittings that m ust be

lubricated regularly with No . 2 General Pur pose

Lithium Base Grease . If the mac hine is operated

under nor mal conditions , lubricate all bearings

and bushings after ev er y 50 hours of operation or

immediately after ev er y w ashing .

Bearings rarely fail from defects in materials or

w orkmanship . T he most common reason for

failure is moisture and contamination w orking

its w a y past the protecti v e seals . Bearings that

are g reased will rely upon regular maintenance to

purg e har mful debris from the bearing area. Sealed

bearings , suc h as the castor wheel bearings , rely on

an initial fill of special g rease and a robust integ ral

seal to k ee p contaminants and moisture out of the

rolling elements .

T he sealed bearings require no lubrication or shor t

ter m maintenance . T his minimizes routine ser vice

required and reduces the potential of turf damag e

due to g rease contamination. T hese sealed bearing

pac kag es will pro vide g ood perfor mance and life

under nor mal use , but periodic inspections of

bearing condition and seal integ rity should be

conducted to a v oid do wntime . T hese bearings

should be inspected seasonally and re placed

34

Loading...

Loading...