ServicingtheCutterBlade

RemovingtheCutterBlade

Theblademustbereplacedifasolidobjectishit,theblade

isoutofbalance,orifthebladeisbent.Alwaysusegenuine

Tororeplacementbladestobesureofsafetyandoptimum

performance.Neverusereplacementbladesmadebyother

manufacturersbecausetheycouldbedangerous.

1.Raisethecuttingdecktothehighestposition,shutthe

engineoff,andengagetheparkingbrake.Blockthe

cuttingdecktopreventitfromfallingaccidentally.

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(Figure62).

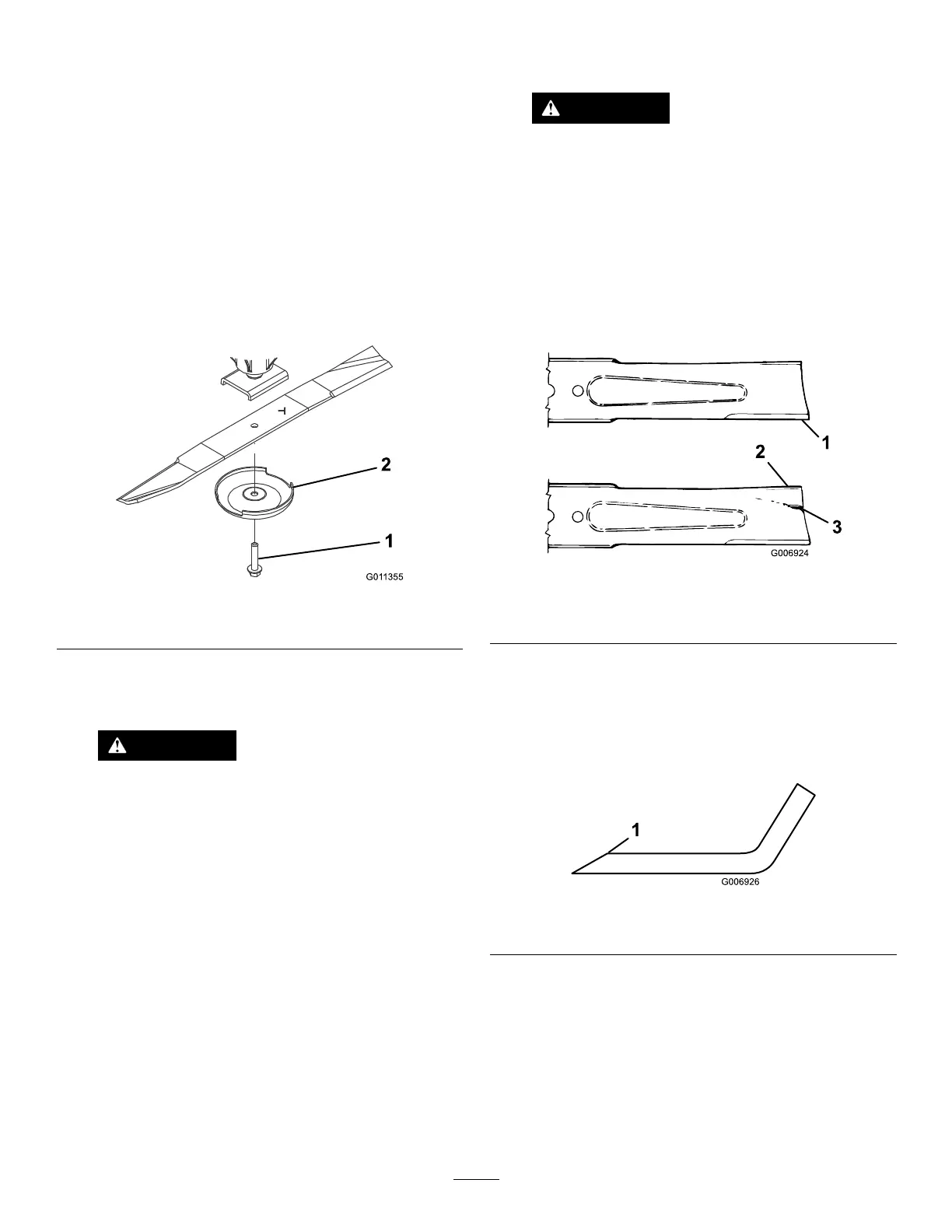

Figure62

1.Bladebolt2.Anti-scalpcup

3.Installtheblade,sailfacingtowardthecuttingdeck,

withtheanti-scalpcupandbladebolt(Figure62).

Tightenbladeboltto115–149N-m(85–110ft-lb).

DANGER

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath

•Inspectthebladeperiodicallyforwearor

damage.

•Neverweldabrokenorcrackedblade.

•Alwaysreplaceawornordamagedblade.

InspectingandSharpeningtheBlade

1.Raisethecuttingdecktothehighestposition,shutthe

engineoff,andengagetheparkingbrake.Blockthe

cuttingdecktopreventitfromfallingaccidentally.

2.Examinethecuttingendsofthebladecarefully,

especiallywheretheatandcurvedpartsoftheblade

meet(Figure63).Sincesandandabrasivematerialcan

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

machine.Ifwearisnoticed(Figure63),replacethe

blade;refertoRemovingtheCutterBlade.

DANGER

Ifthebladeisallowedtowear,aslotwillform

betweenthesailandatpartoftheblade

(Figure63).Eventuallyapieceoftheblade

maybreakoffandbethrownfromunderthe

housing,possiblyresultinginseriousinjuryto

yourselforbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Alwaysreplaceawornordamagedblade.

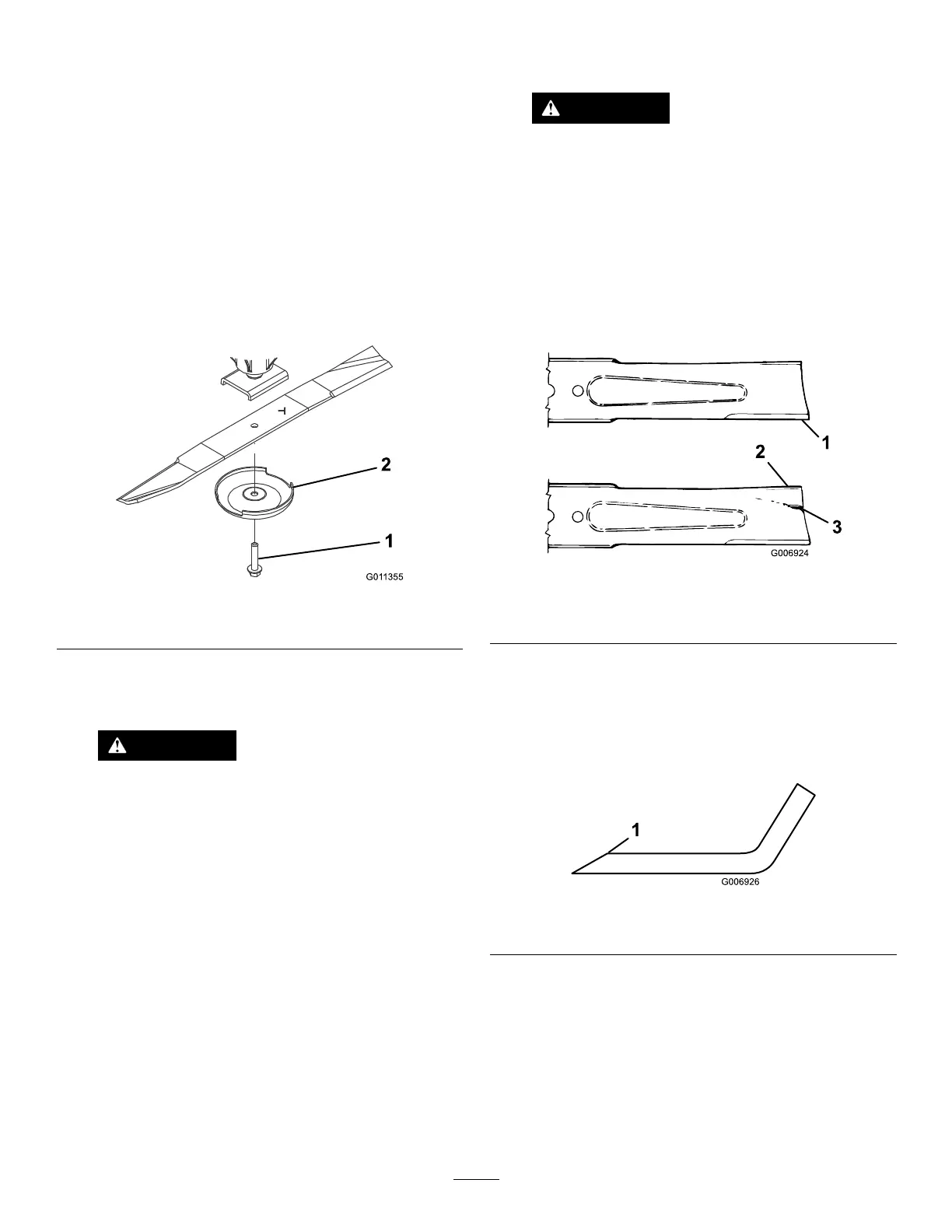

Figure63

1.Cuttingedge3.Wear/slot/crack

2.Sail

3.Inspectthecuttingedgesofallblades.Sharpenthe

cuttingedgesiftheyaredullornicked.Sharpenonly

thetopofthecuttingedgeandmaintaintheoriginal

cuttingangletomakesureofsharpness(Figure64).

Thebladewillremainbalancedifthesameamountof

metalisremovedfrombothcuttingedges.

Figure64

1.Sharpenatthisangleonly

4.Tocheckthebladeforbeingstraightandparallel,lay

thebladeonalevelsurfaceandcheckitsends.The

endsoftheblademustbeslightlylowerthanthecenter,

andthecuttingedgemustbelowerthantheheelofthe

blade.Thisbladewillproducegoodqualityofcutand

requireminimalpowerfromtheengine.Bycontrasta

bladethatishigherattheendsthanthecenter,orif

cuttingedgeishigherthantheheel,thebladeisbentor

warpedandmustbereplaced.

46

Loading...

Loading...